Combined coal pyrolysis gasification system

A pyrolysis gasification and combined technology, which is used in granular/powder fuel gasification, chemical industry, manufacture of combustible gas, etc., can solve the problem of reducing the full utilization of effective components in coal, and achieve the effect of improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

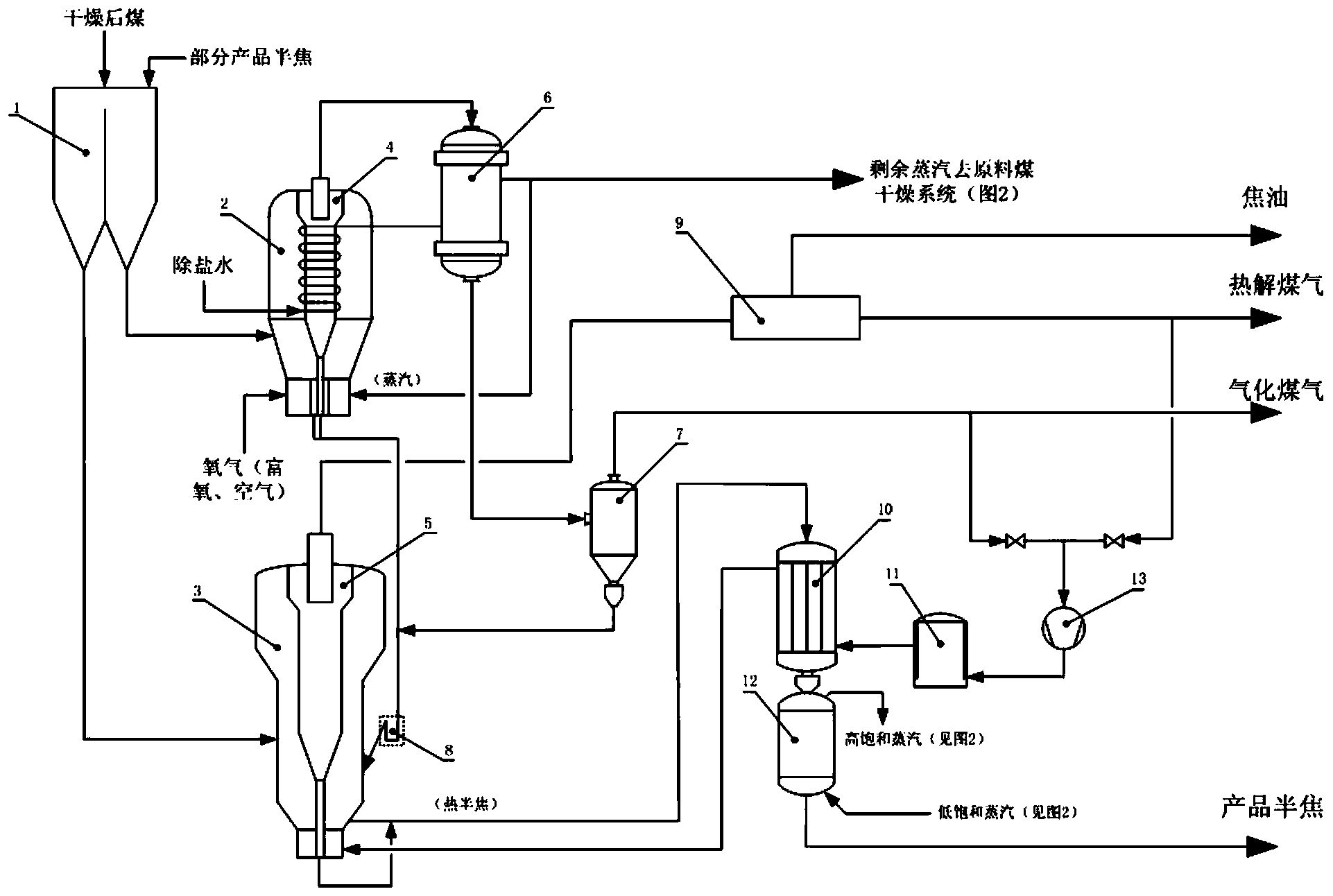

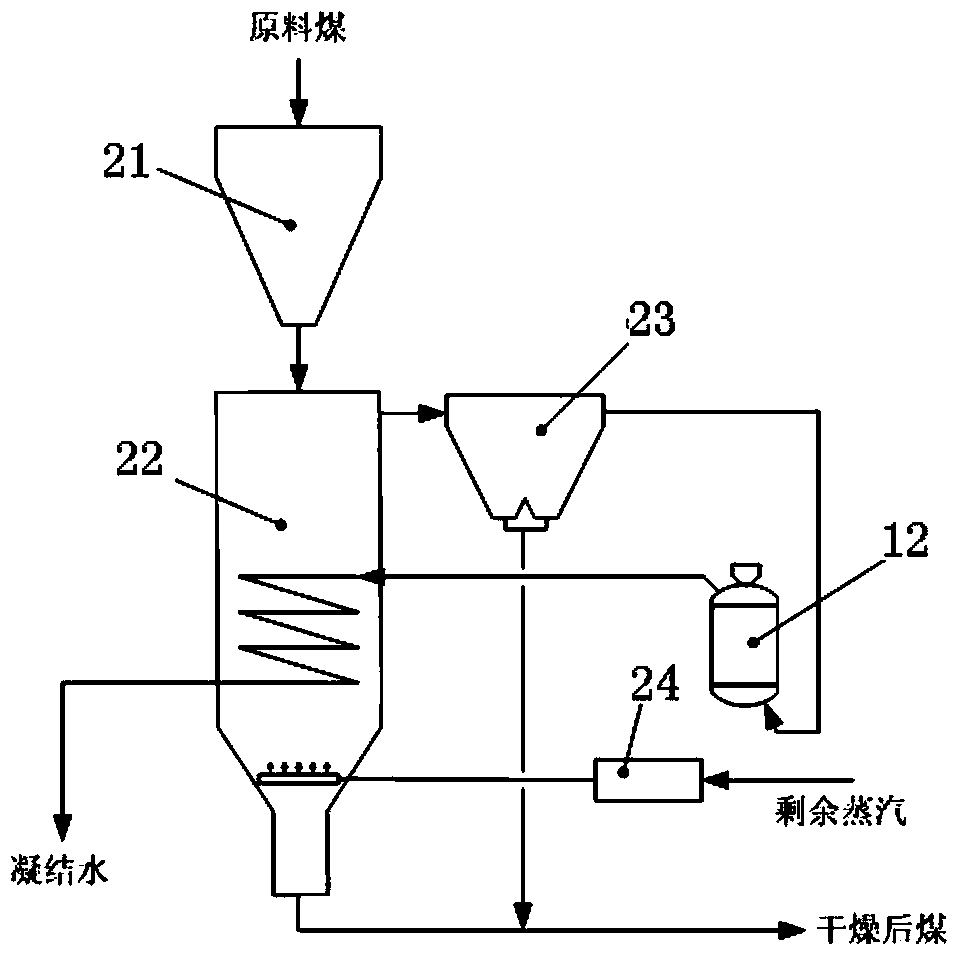

[0020] Combined briquette pyrolysis gasification system of the present invention, its preferred embodiment is:

[0021] It includes a composite coal bunker, a combined gasifier and a combined pyrolysis furnace. The feed port of the type gasifier is connected, and the other discharge port is connected with the feed port of the combined pyrolysis furnace;

[0022] The operation mode of the combined gasifier is in the form of a fluidized bed, and there is a built-in separator in the gasifier in the form of multi-inlet and cyclone separation. The central axis of the built-in separator in the gasifier is in line with the The central axis of the gasifier coincides, the top is flush with the top of the combined gasifier, and a hot gas outlet pipe is provided;

[0023] The hot gas outlet pipe is connected to the air inlet of the shell-and-tube waste heat boiler, the gas outlet of the shell-and-tube waste heat boiler is connected to the air inlet of the hard tube dust collector, and t...

specific Embodiment

[0032] like figure 1 As shown, the treated raw coal and the semi-coke produced by the system are sent to the lower part of the combined gasifier 2 through the composite coal bunker 1; The co-action of the combined gasifier generates heat and performs partial gasification; the semi-coke produced by the combined gasifier 2 and the semi-coke powder separated by the built-in separator 4 of the gasifier pass through the semi-coke at the bottom of the combined gasifier 2 respectively. The outlet and the separated ash outlet of the separator are sent to the hot semi-coke return valve 8 connected with the combined pyrolysis furnace 3, and then sent into the combined pyrolysis furnace 3. At the same time, the gasification hot coal gas produced in the combined gasifier 2 enters the hot gas inlet of the shell-and-tube waste heat boiler 6 through the outlet pipe of the built-in separator 4 of the gasifier; After exchanging heat with desalted water in 6, the temperature is lowered to abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com