Calcium carbide preparation system and method

A preparation system and technology of calcium carbide, applied in sustainable manufacturing/processing, carbide, chemical industry, etc., can solve the problems of reducing the quality of calcium carbide and increasing energy consumption, so as to reduce the introduction of ash, reduce the consumption of carbon materials, and increase energy The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

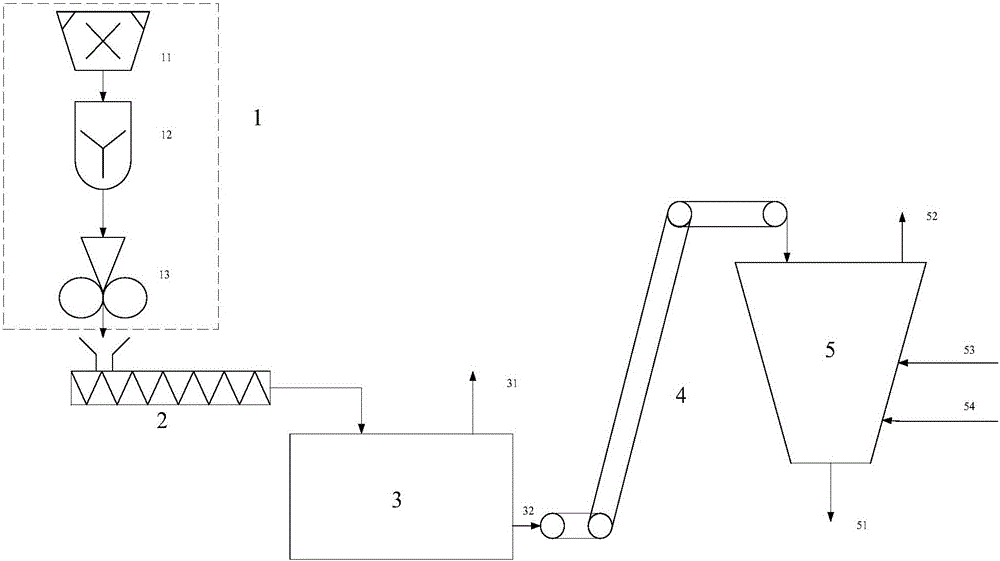

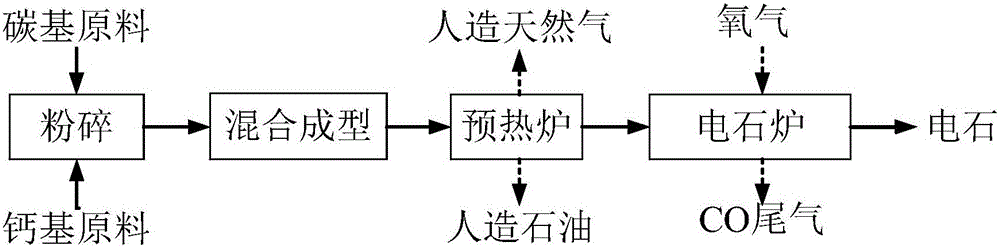

[0034] figure 1 Schematic diagram of the composition and structure of the preparation system of calcium carbide provided by the present invention, such as figure 1 As shown, the preparation system includes: raw material pretreatment unit 1, feeding device 2, preheating furnace 3, high temperature conveying device 4 and calcium carbide furnace 5; wherein,

[0035] The raw material pretreatment unit 1 includes a crushing device 11, a mixing device 12 and a molding device 13 connected in sequence; the outlet of the molding device 13 communicates with the inlet of the feeding device 2;

[0036] The outlet of the feeding device 2 communicates with the inlet of the preheating furnace 3;

[0037] The preheating furnace 3 is provided with a solid material outlet 32 and an oil gas outlet 31, and the solid material outlet 32 is connected with the high-temperature conveying device 4;

[0038] The outlet of the high-temperature conveying device 4 communicates with the high-temperatu...

Embodiment 1

[0061] The long-flame coal and quicklime with a particle size of less than 5mm are finely ground and dried by jet mill respectively, and the long-flame coal powder and quicklime powder whose particle size is less than 0.07mm-0.05mm account for more than 90% are respectively obtained. The industrial analysis of flame coal is shown in Table 1. The content of quicklime (CaO) is 92%, and then the long-flame coal powder and quicklime powder are transported into the batching tank through gas. According to the weight ratio, quicklime powder: long-flame coal powder=0.6 :1 for mixing, the mixed powder gas is transported to the molding unit for molding, and the pellets with a particle size of 15×5×10mm are obtained, which are directly transported by the belt to the bunker on the top of the radiant tube rotary hearth furnace, and the vibrating distribution machine is used The material is distributed to the bottom of the rotary hearth furnace with a thickness of 20mm. Then, with the rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com