Tunnel kiln for firing ceramic items

A tunnel type, article technology, applied in the field of building material manufacturing, can solve the problems of bursting of roasted articles, and achieve the effect of increasing gas consumption, reducing heat consumption and reasonable temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

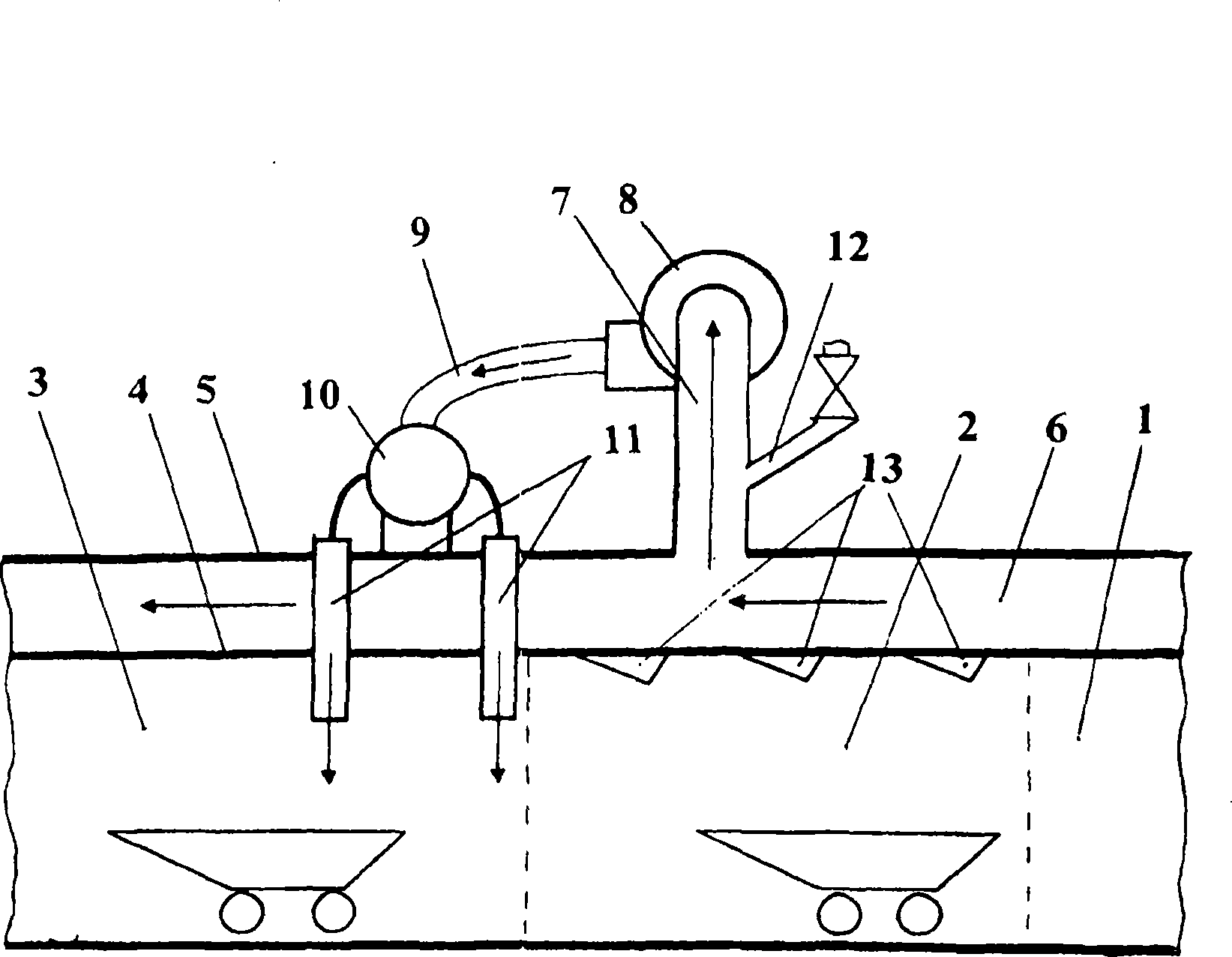

[0013] Position 1 represents the preheating section of the processing channel, position 2—firing section, and position 3—cooling section. Between the main vaulted roof 4 and the additional vaulted roof 5 there is an inner vaulted space 6 . The gas distribution (ventilation) system consists of a suction line 7, a ventilator 8, a feed line 9 and a collector-distributor 10 with a main pipe 11; Connected with the ventilator 8, the main pipe 11 of the collector-distributor 10 is directly output to the cooling section 3 near the firing section 2 of the processing channel. Position 13 indicates the burner located in firing section 2. The ventilation system may comprise several fans 8 with a corresponding number of connecting lines. However, the kiln can supply a certain portion of the gas supplied to the atmosphere and pipelines to feed hot gas to the preheating section 1 of the ceramic objects through exhaust ventilation (such constructional elements are not shown in the drawings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com