Ton bag extruding machine

An extruder, ton bag technology, applied in grain processing and other directions, can solve the problems of inability to carry out loading and unloading, inability to squeeze at multiple angles, and difficult to feed materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

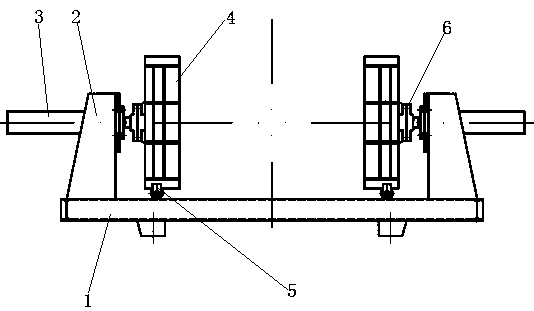

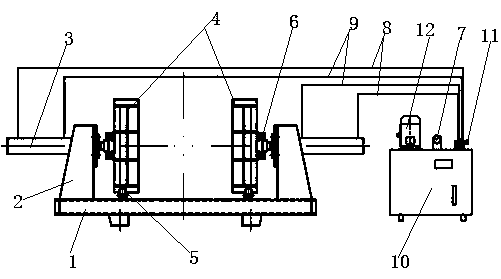

[0015] Such as Figure 1 to Figure 3 The big bag extrusion machine shown includes a base 1, and a support plate assembly 2 is fixed on both sides of the top surface of the base 1; a hydraulic cylinder 3 is fixed on the two support plate assemblies 2; There is an extruding plate 4 between them; pulleys 5 are arranged at the bottom of both sides of the extruding plate 4; The middle part of the outer side is fixed; the hydraulic cylinder 3 is connected to the hydraulic station 10 through the advancing oil pipe 8 and the retreating oil pipe 9; the pushing oil pipe 8 and the returning oil pipe 9 are provided with a pressure regulating valve 11; the hydraulic station 10 is provided with an oil pump The motor 12 and the pressure display gauge 7; the left and right swing range of the two extruding plates 4 is 2~3°; the axes of the two hydraulic cylinders 3 are on the same center line; the two extruding plates 4 are upper, lower, and upper Small bell mouth structure; before starting t...

Embodiment 2

[0017] Such as Figure 4 with Figure 5 As shown, the big bag extrusion machine of this embodiment is basically the same as that of Embodiment 1, wherein a bearing 13 is fixed through the center of the base 1; a rotating shaft 14 is installed inside the bearing 13; the top surface of the rotating shaft 14 is installed There is a turntable 15; the turntable 15 is movably installed on the outer bearing 16 on the top surface of the base; the bottom surface of the rotating shaft 14 is equipped with a drive disc 17; the drive disc 17 is connected to the reducer 18 through a transmission belt; the outer diameter of the pulley 5 is It is greater than the height of the turntable 15 and the outer bearing 16 after installation; the front and rear sides of the top of the base 1 are attached to the feeding and discharging conveyor belt 19; one end of the feeding and discharging conveyor belt 19 is close to the turntable 15, and the other end is close to the top and bottom of the slope str...

Embodiment 3

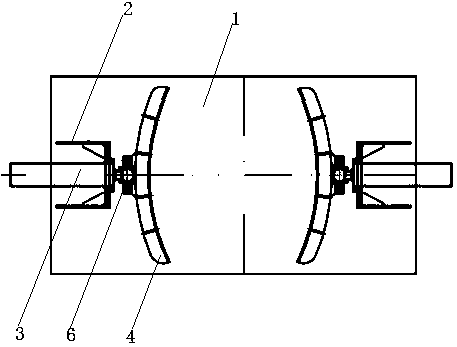

[0019] Such as Figure 5 with Image 6As shown, the big bag extrusion machine of this embodiment is basically the same as that of Embodiment 1, and the two sides of the extrusion plate 4 are axially provided with straight through grooves 22; the inside of the straight through grooves 22 is embedded with internal pressure The seat body 23; the front side of the internal pressure seat body 23 is provided with a plurality of rolling grooves 24 at intervals; the upper and lower sides of the rolling grooves 24 are fixed with inner bearings 25; rollers 26 are installed between the inner bearings 25; The roller 26 protrudes from the inner pressure seat body 23; the upper and lower sides of the rear side of the inner pressure seat body 23 are fixed with slide bars 27; the inner pressure seat body 23 is fixed with multiple sets of strong springs 28 between the two slide bars; The other end of the powerful spring 28 is fixed to the self-locking sliding seat 29; the upper and lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com