Mobile phone curved glass hot bending composite die with temperature regulation function and control method

A curved glass and composite mold technology, which is applied in glass manufacturing equipment, glass molding, glass reshaping, etc., can solve the problems of easy offset, cracks and bubbles, and large bending stress at the edge of the glass. Achieve the effect of improving precision and reducing the generation of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

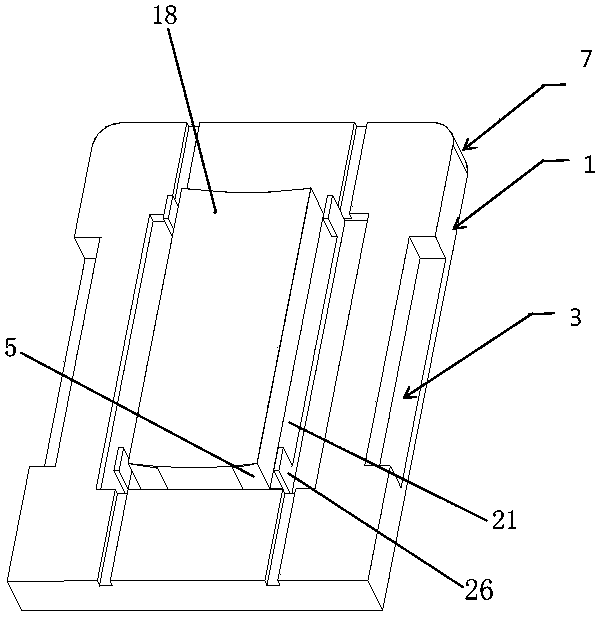

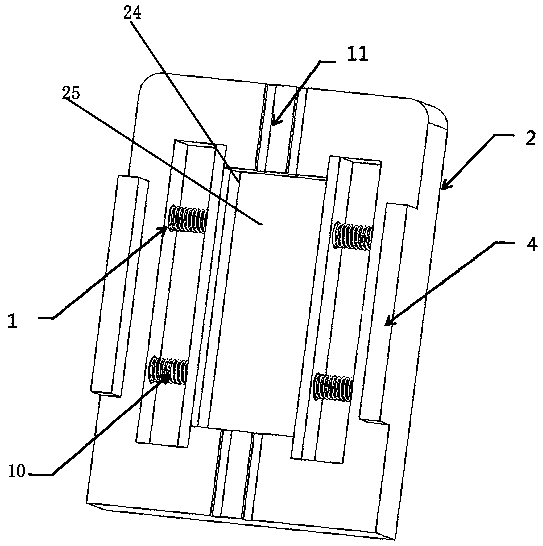

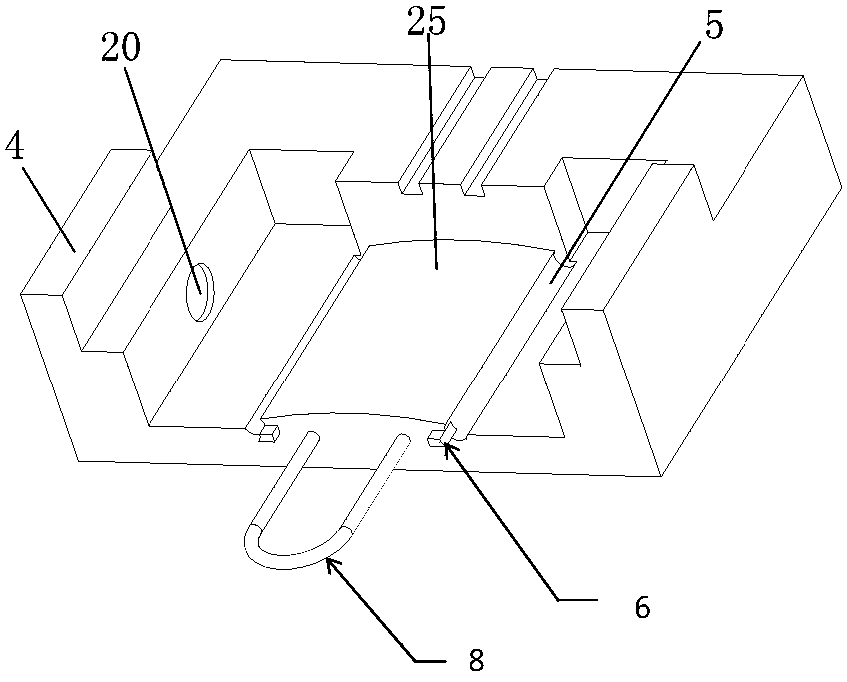

[0035] as attached Figure 1-8 As shown, on the one hand, the present invention discloses a mobile phone curved surface glass hot-bending composite mold with temperature control, including a die 1 and a bottom die 2, a cavity 24 is provided in the bottom die 2, and both sides of the die 1 Grooves 3 are respectively provided, and the two sides of the bottom mold 2 are provided with bosses 4 meshing with the grooves 3, the edges of the grooves 3 and the bosses 4 are the same curved surface, and the center of the die 1 is provided with a die curved surface 18 , the cavity 24 is provided with an open cavity surface 25, the mold surface 18 and the cavity surface 25 are curved surfaces with the same curvatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com