Bending mechanism for flexible flat cable assembly device

A technology for assembling equipment and bending mechanisms, applied in the direction of lines/collector parts, electrical components, circuits, etc., can solve problems such as easy movement, wrong bending position of core wire, tilting movement, etc., and achieve high bending accuracy , Safe and reliable processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

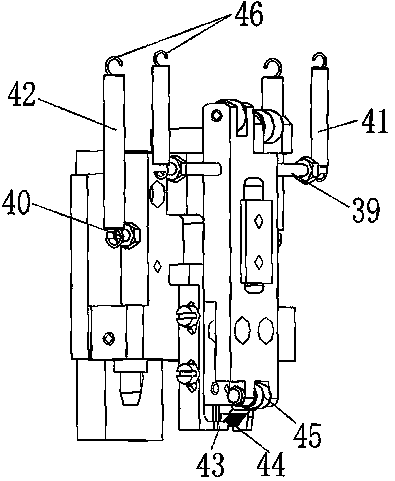

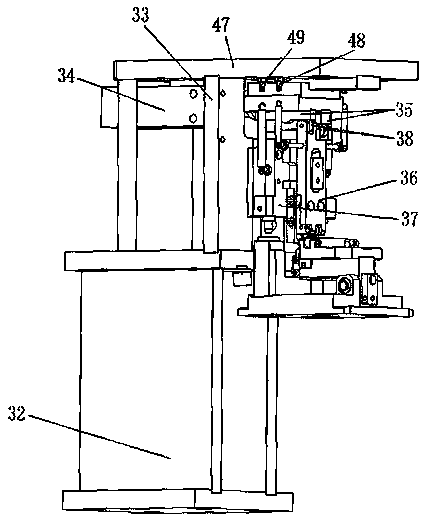

[0014] Such as Figure 1-2 As shown, a bending mechanism of flexible cable assembly equipment includes a base 32, a rear plate 33, a top plate 47, a cylinder 34, two cams 38, two inclined blocks 35, a front moving plate 36, a rear moving plate 37 and The bending knife 44 is provided with a back plate 33 above the base 32, a top plate 47 is provided at the top of the back plate 33, and two movable oblique blocks 35 are arranged below the top plate 47. After the cylinder rod of the cylinder 34 passes through the The plate is connected with the slanting block 35, and a front moving plate 36 and a rear moving plate 37 are respectively provided below the two slanting blocks 35, and the top of the front moving plate 36 and the rear moving plate 37 is equipped with a corresponding slanting block 35 slopes. The cam 38 is provided with a pressing wheel 45 at the bottom of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com