Pipe bending tooling

A technology for bending and pipe fittings, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the qualified rate of elbows, difficult to control the distance between two bends, etc., and achieve the effect of improving the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

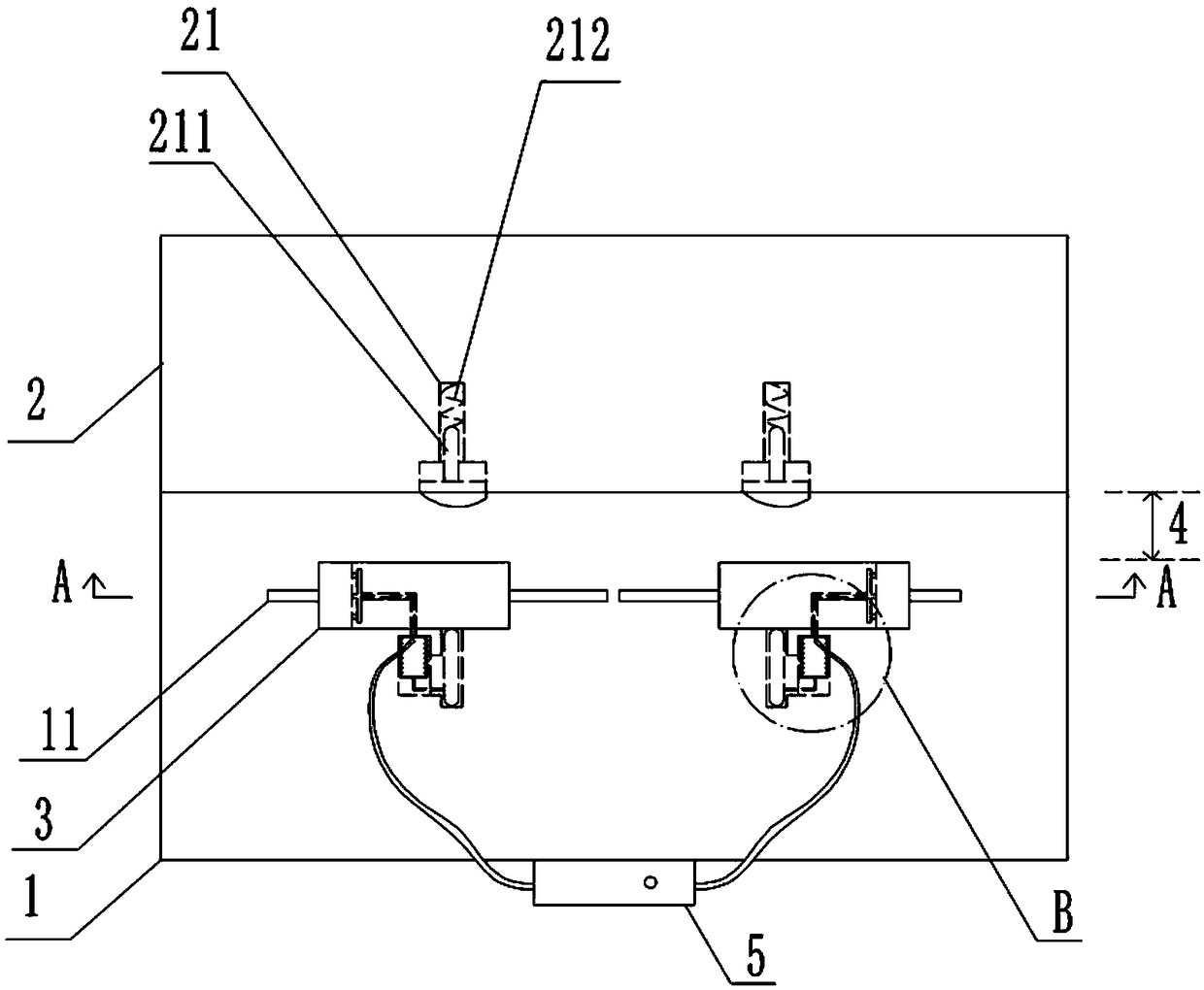

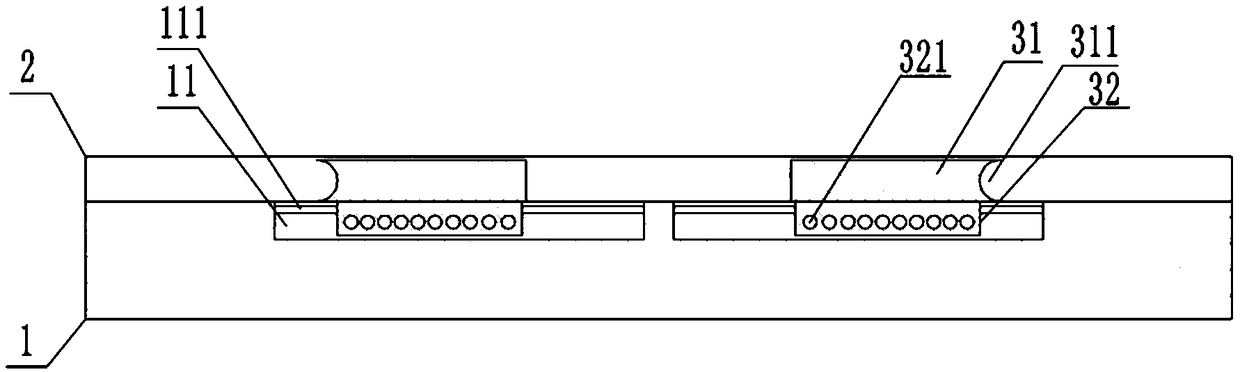

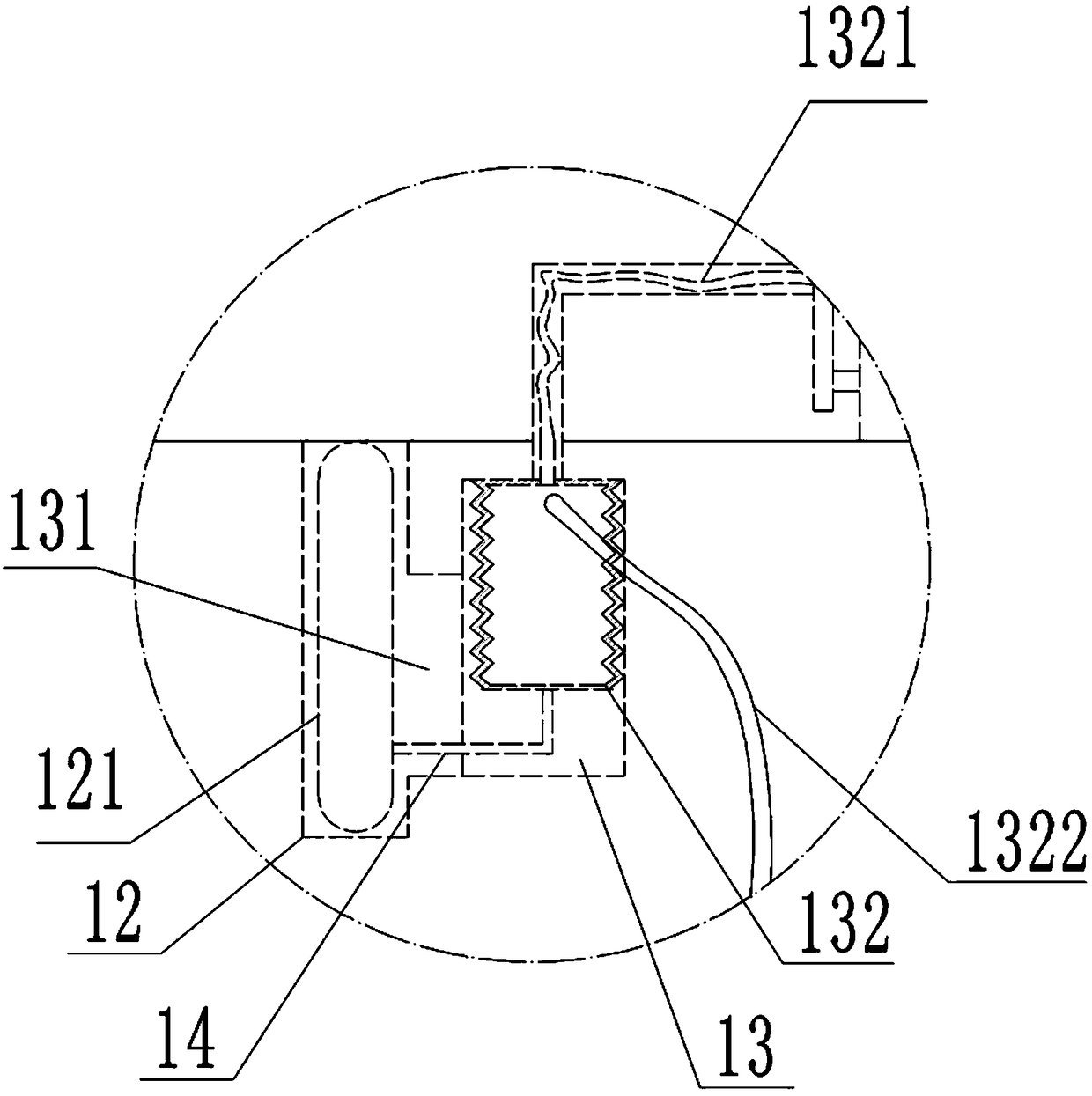

[0023] The reference signs in the drawings of the description include: processing table 1, strip chute 11, strip side groove 111, positioning cavity 12, positioning column 121, extrusion cavity 13, connecting hole 131, elastic air bag 132, liquid outlet pipe 1321, liquid inlet pipe 1322, L-shaped push rod 14, positioning platform 2, sliding hole 21, slide block 211, spring 212, adjustment block 3, block body 31, arc groove 311, sliding block 32, positioning hole 321, place Channel 4, storage tank 5.

[0024] The embodiment is basically as figure 1 , figure 2 and image 3 As shown, the pipe bending tooling includes a processing table 1, a positioning table 2 and an adjustment block 3 are arranged on the processing table 1, the positioning table 2 is fixedly connected to one side of the processing table 1, and the adjustment block 3 is connected to the other side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com