Automatic pipe bender for stainless steel pipes and bending method thereof

A stainless steel pipe and pipe bending machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of piston cylinder stroke, driving force cannot be adjusted accurately, reduce the bending efficiency of the pipe bender, and cannot be precisely bent, etc. problems, to achieve the effect of improving bending accuracy and bending stability, reducing labor intensity and labor costs, and improving bending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

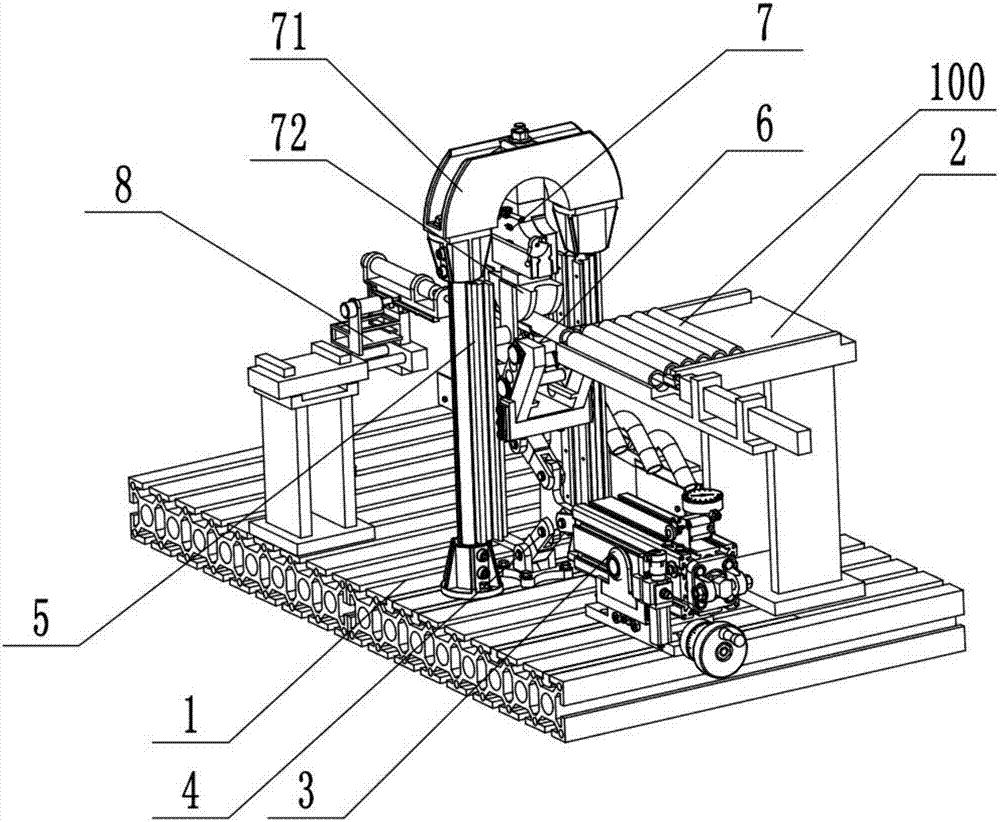

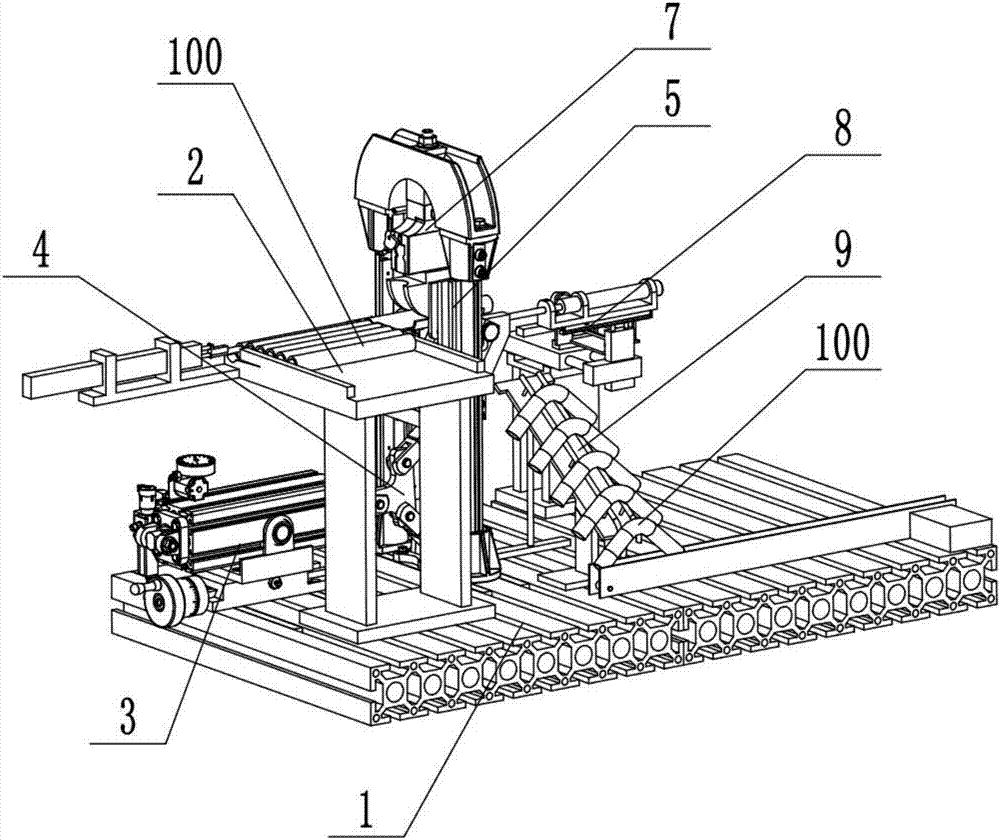

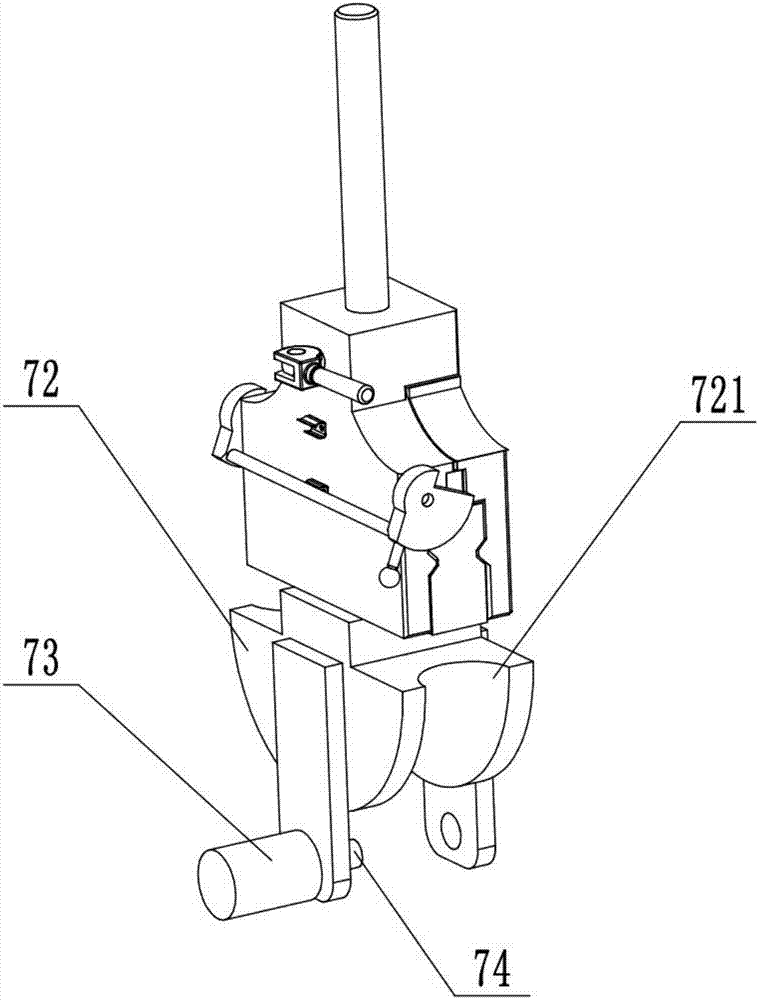

[0046] Such as Figure 1 to Figure 4 As shown, the stainless steel pipe automatic pipe bending machine of this embodiment includes a base 1, a bending frame 5 installed on the base, a bending head assembly 7 fixed on the upper end of the bending frame 5, and can be vertically mounted on the bending frame 5. To the sliding bending seat 6 and the bending driving device for driving the bending seat 6, the bending hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com