Three-dimensional ultrasonic vibration cutting working head

A vibrating cutting and three-dimensional ultrasonic technology is applied in the direction of metal processing equipment, fluid using vibration, metal processing machinery parts, etc., to achieve the effect of reducing surface roughness, improving processing performance and ensuring reliable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

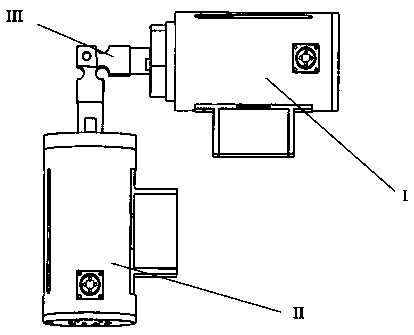

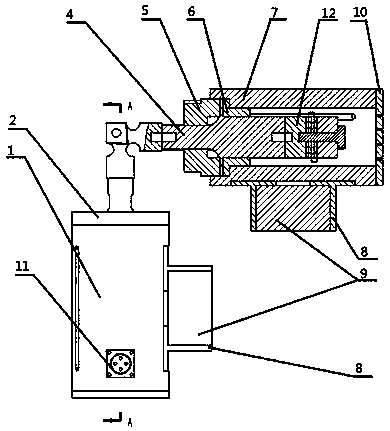

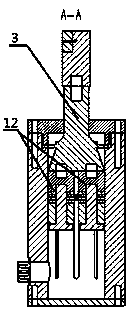

[0021] Embodiment 1: as Figure 1-7 As shown, a three-dimensional ultrasonic vibration cutting machining head includes three parts: X ultrasonic vibrating arm I, Y ultrasonic vibrating arm II and cutter head III; the front end of X ultrasonic vibrating arm I and the front end of Y ultrasonic vibrating arm II The cutter head III is connected orthogonally through flexible hinges; the clamping of the two vibrating arms is designed in strict accordance with the installation dimensions of the standard four-station tool holder to facilitate installation and use on the machine tool.

[0022] Further, it can be set that the X ultrasonic vibrating arm I is composed of a chuck 5, a sleeve 6, an X arm ultrasonic vibrator, a cylinder I7, a T-shaped positioning block 8, a cuboid positioning block 9, a cylinder rear end cover 10, an aviation The X-arm ultrasonic vibrator consists of a plug 11; the X-arm ultrasonic vibrator includes a horn I4 and an ultrasonic transducer 12, and the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com