Elevator door plate production line

A production line and door panel technology, applied in storage devices, metal processing equipment, feeding devices, etc., can solve the problems of incoherent movement of elevator door panels and wall panels, failure to realize automatic turnover transportation, increase labor intensity of operators, etc., and achieve reduction The effect of material turnover, avoiding loss and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

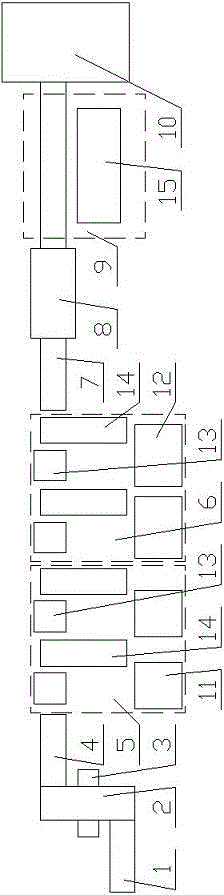

[0053] combine Figure 1~Figure 6 As shown, the present invention sequentially includes a wool material feeding device 1, a feeding transfer frame 2, a punching device 3, a bending device, a riveting device 8, an upper rib area 9 and a blanking transfer frame 10, and the punching device 3 and the bending device is provided with a conveying frame A4, between the bending device and the riveting device 8 is provided with a conveying frame B7, and the loading and transferring frame 2 is arranged on the feeding device 1, punching device 3 and Above the conveying frame A4, the conveying frame B7 is connected with the unloading and moving carrier 10 through the riveting device 8 and the ribbing device 9; the riveting device 8 is arranged on the conveying frame B7.

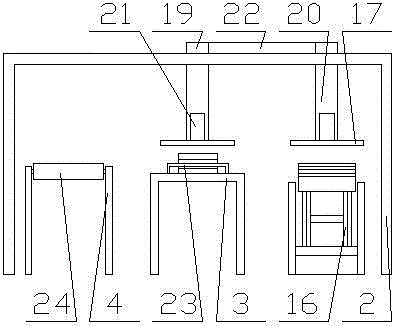

[0054] The feeding device 1 includes a lifting platform 16 , and the lifting platform 16 is located below the loading and transferring frame 2 .

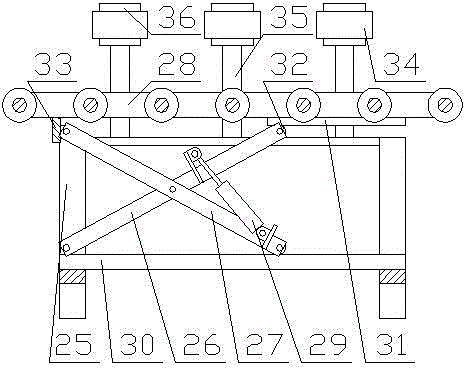

[0055] The lifting platform 16 includes a frame A25, and the top of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com