Metal plate bending method and terminal

A sheet metal and bending machine technology, applied in metal processing, metal processing equipment, feeding devices, etc., can solve the problems of low production efficiency and high cost, and achieve the effect of improving efficiency, improving accuracy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

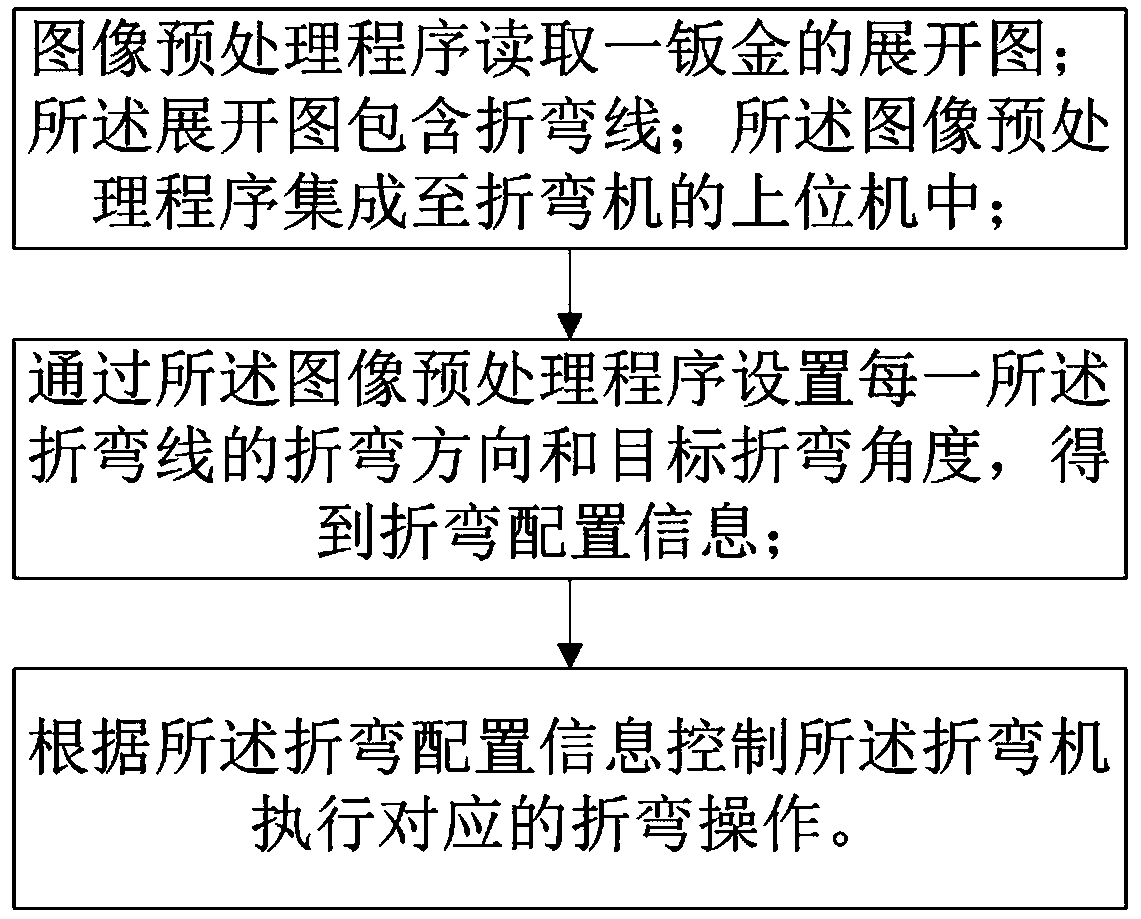

[0087] Such as figure 1 As shown, the present embodiment provides a sheet metal bending method, including:

[0088] S1. The image preprocessing program reads an unfolded view of a sheet metal; the unfolded view includes bending lines; the image preprocessing program is integrated into the host computer of the bending machine.

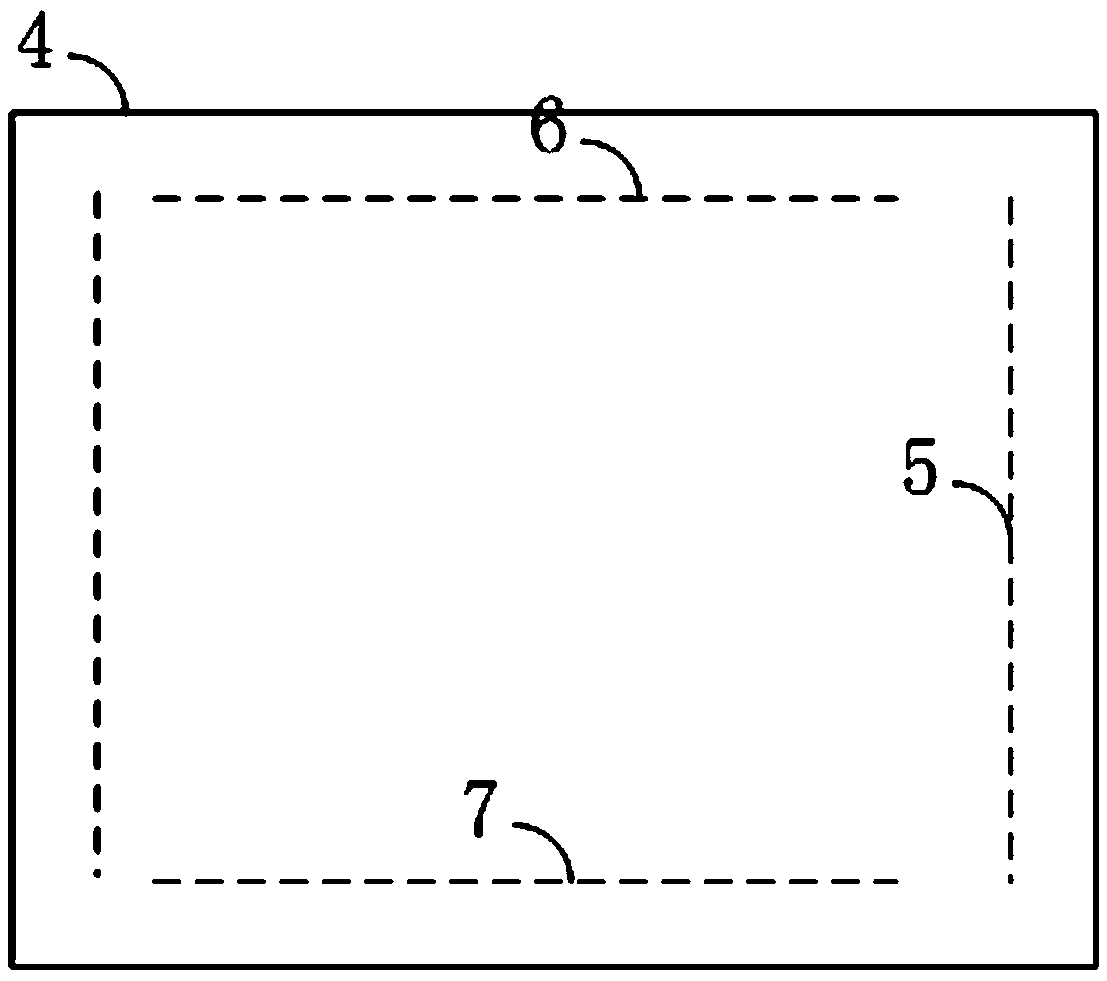

[0089] in, figure 2 It is an expanded view of a sheet metal, and the expanded view includes a first bending line 5 , a second bending line 6 and a third bending line 7 . The image preprocessing program can identify bend lines in the unfolded diagram and set configuration information for the bend lines.

[0090] S2. Set the bending direction and target bending angle of each of the bending lines through the image preprocessing program to obtain bending configuration information. Specifically:

[0091] S21. Select a bending line in the expanded view to obtain the current bending line;

[0092] S22. Select a bending direction from the preset drop-down...

Embodiment 2

[0184] Such as Figure 16 As shown, this embodiment provides a sheet metal bending terminal, including one or more processors 9 and a memory 10, the memory 10 stores a program and is configured to be executed by the one or more processors 9 The following steps:

[0185] S1. The image preprocessing program reads an unfolded view of a sheet metal; the unfolded view includes bending lines; the image preprocessing program is integrated into the host computer of the bending machine.

[0186] in, figure 2 It is an expanded view of a sheet metal, and the expanded view includes a first bending line 5 , a second bending line 6 and a third bending line 7 . The image preprocessing program can identify bend lines in the unfolded diagram and set configuration information for the bend lines.

[0187] S2. Set the bending direction and target bending angle of each of the bending lines through the image preprocessing program to obtain bending configuration information. Specifically:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com