Preparation process of scratch-resistant glass with flashing sand effect

A preparation process and anti-scratch technology, applied in the coating and other directions, can solve the problems of poor adhesion, easy scratches, and easy aging of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

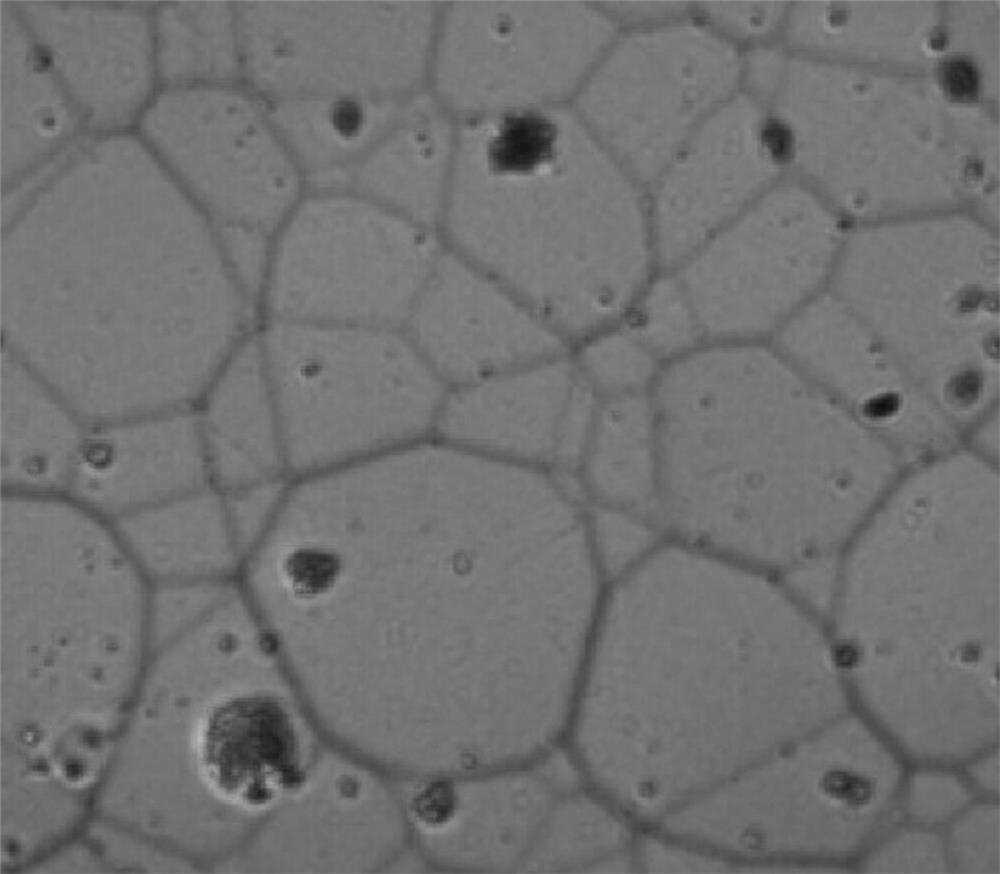

Image

Examples

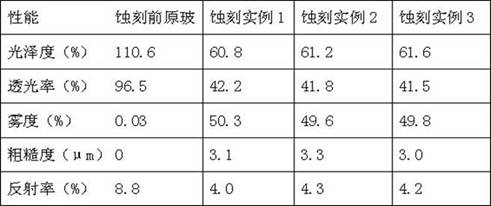

Embodiment 1

[0017] 1. Prepare crystal diamond flash point effect glass etching solution (wt%) according to the following formula: NH 4 HF 2 20.6%, ALF 3 13.5%, H 3 PO 4 13.8%, HNO 3 12.7%, K 2 SO 4 4.8%, Na 2 S 2 o 3 3.3%, K 2 SiF 6 0.5%, sodium alkyl sulfate 0.3%, glycerol 4.8%, H 2 O 25.7%; Add the above-mentioned raw materials in sequence according to the etching process requirements, and then fully stir evenly to present a uniform and stable supersaturated solution state, and leave it to stand and mature for 24-72 hours at room temperature to obtain a satisfactory etching solution. You can start the etching treatment of the anti-scratch crystal diamond flash point effect glass of the original glass sheet.

[0018] 2. Use anti-etching ink to protect the side of the original glass that does not need to be etched;

[0019] 3. Clean the side of the original glass sheet that needs to be etched with the pretreatment solution, and put it into the etching solution in a wet s...

Embodiment 2

[0023] 1. Prepare crystal diamond flash point effect glass etching solution (wt%) according to the following formula: NH 4 HF 2 23.6%, ALF 3 14.8%, H 3 PO 4 13.6%, HNO 3 12.7%, K 2 SO 4 4.0%, Na 2 S 2 o 3 3.8%, K 2 SiF 6 0.6%, sodium alkyl sulfate 0.3%, glycerin 5.0%, H 2 O 21.6%; Add the above-mentioned raw materials in turn according to the etching process requirements, and then fully stir evenly to present a uniform and stable supersaturated solution state, and leave it to mature for 24-72 hours at room temperature to obtain a satisfactory etching solution. You can start the etching treatment of the anti-scratch crystal diamond flash point effect glass of the original glass sheet;

[0024] 2. Use anti-etching ink to protect the side of the original glass that does not need to be etched;

[0025] 3. Clean the side of the original glass sheet that needs to be etched with the pretreatment solution, and put it into the etching solution in a wet state for immer...

Embodiment 3

[0029] 1. Prepare crystal diamond flash point effect glass etching solution (wt%) according to the following formula: NH 4 HF 2 24.3%, ALF 3 12.8%, H 3 PO 4 14.5%, HNO 3 11.5%, K 2 SO 4 4.1%, Na 2 S 2 o 3 3.3%, K 2 SiF 6 0.6%, sodium alkyl sulfate 0.3%, glycerol 4.9%, H 2 O 23.7%; add the above-mentioned raw materials in sequence according to the etching process requirements, and then fully stir evenly to present a uniform and stable supersaturated solution state, and leave it to mature at room temperature for 24-72 hours to obtain a special etching solution that meets the requirements , you can start the etching treatment of the anti-scratch crystal diamond flash point effect glass of the original glass sheet;

[0030] 2. Use anti-etching ink to protect the side of the original glass that does not need to be etched;

[0031] 3. Clean the side of the original glass sheet that needs to be etched with the pretreatment solution, and put it into the etching solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com