Coated glass and processing method thereof

A technology of coated glass and processing method, which is applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of high cost, hardness, strength and insufficient anti-fouling, etc., and achieve strong anti-drop effect, Guaranteed firmness, uniform and tight plating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

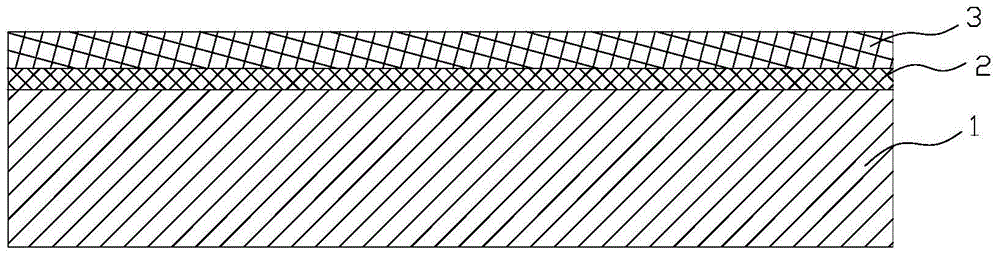

[0020] A kind of coated glass and its processing method, please refer to figure 1 , including a glass substrate 1, one surface of the glass substrate 1 is sequentially coated with SIO 2 Layer 2, AL 2 o 3 Layer 3.

[0021] Its processing method comprises the following steps:

[0022] 1) Arranging the targets: SIOs are respectively arranged in the 8 cavities arranged in sequence in the vacuum sputtering coating equipment 2 target, SIO 2 target, SIO 2 Target, AL 2 o 3 Target, AL 2 o 3 Target, AL 2 o 3 Target, AL 2 o 3 target and AL 2 o 3 target, each setting SIO 2 The set power in the cavity of the target is 6KW, each setting AL 2 o 3 The power set in the cavity of the target is 8KW;

[0023] 2) The temperature of all chambers is set to 150 degrees, the voltage is set to 420V, and the current is 15A;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com