Matt oleophobic and hydrophobic melamine-urea-formaldehyde impregnated bond paper and preparing method and application thereof

An adhesive paper, matte technology, used in paper, papermaking, paper coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

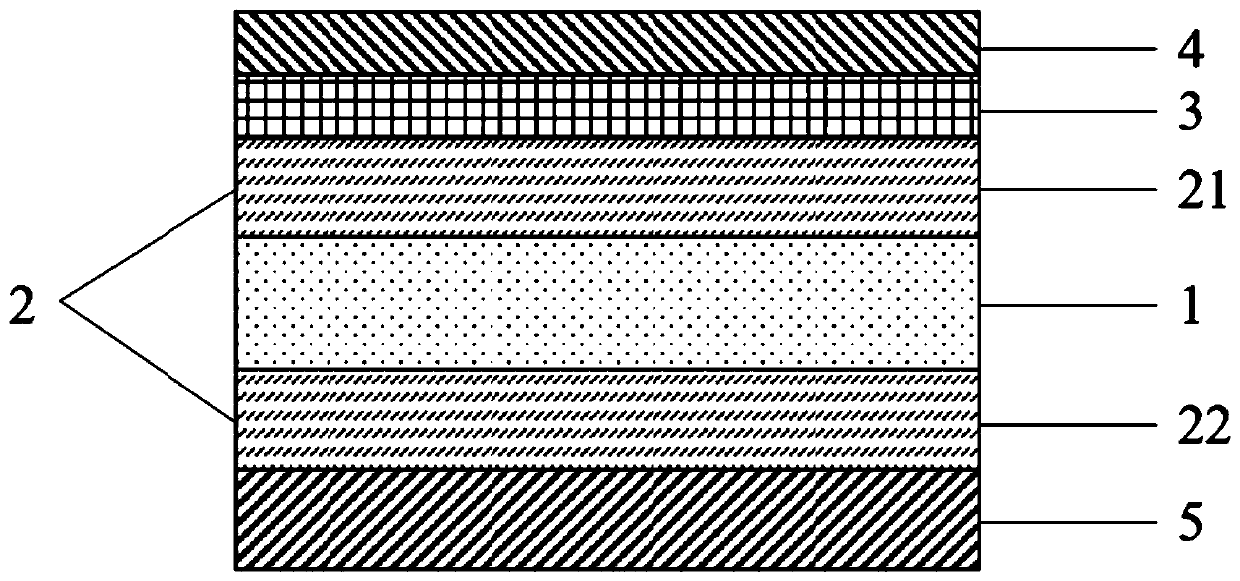

Image

Examples

Embodiment 1

[0058] The preparation method of the matte oleophobic hydrophobic facing adhesive film paper in this example is as follows:

[0059] 1) First time gluing: impregnate the printed decorative base paper with urea-formaldehyde resin, the amount of resin impregnated in the base paper is 80g per square meter, and then dry in a three-section oven (the temperature of the three-section oven is set to 145℃, 160℃, 150℃) , A semi-finished product of printed decorative paper is obtained.

[0060] 2) Second time gluing: spray matte melamine formaldehyde resin on the front of semi-finished printed decorative paper A. The matte melamine formaldehyde resin is composed of the following parts by mass: 100 parts of melamine formaldehyde resin, matting powder emulsion 8 parts, curing agent 1.2 parts, release agent 0.2 parts, anti-sticking agent 0.2 parts, dust removal agent 0.2 parts. These raw materials are weighed according to the proportion, mixed and stirred to obtain the matte melamine formaldehy...

Embodiment 2

[0068] The preparation method of the matte oleophobic hydrophobic facing adhesive film paper in this example is as follows:

[0069] 1) First time gluing: impregnate the printed decorative base paper with urea-formaldehyde resin, the amount of resin impregnated in the base paper is 80g per square meter, and then dry in a three-section oven (the temperature of the three-section oven is set to 145℃, 160℃, 150℃) , A semi-finished product of printed decorative paper is obtained.

[0070] 2) Second time gluing: spray matte melamine formaldehyde resin on the front of semi-finished printed decorative paper A. The matte melamine formaldehyde resin is composed of the following parts by mass: 100 parts of melamine formaldehyde resin, matting powder emulsion 8 parts, curing agent 1.2 parts, release agent 0.2 parts, anti-sticking agent 0.2 parts, dust removal agent 0.2 parts. These raw materials are weighed according to the proportion, mixed and stirred to obtain the matte melamine formaldehy...

Embodiment 3

[0078] The preparation method of the matte oleophobic hydrophobic facing adhesive film paper in this example is as follows:

[0079] 1) First time gluing: impregnate the printed decorative base paper with urea-formaldehyde resin, the amount of resin impregnated in the base paper is 80g per square meter, and then dry in a three-section oven (the temperature of the three-section oven is set to 145℃, 160℃, 150℃) , A semi-finished product of printed decorative paper is obtained.

[0080] 2) Second time gluing: spray matte melamine formaldehyde resin on the front of semi-finished printed decorative paper A. The matte melamine formaldehyde resin is composed of the following parts by mass: 100 parts of melamine formaldehyde resin, matting powder emulsion 8 parts, curing agent 1.2 parts, release agent 0.2 parts, anti-sticking agent 0.2 parts, dust removal agent 0.2 parts. These raw materials are weighed according to the proportion, mixed and stirred to obtain the matte melamine formaldehy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com