A kind of anti-fingerprint facing film paper and its preparation method and application

A technology of glued paper and fingerprints, which is applied in papermaking, paper coating, textiles and papermaking, etc., and can solve problems such as difficult to remove fingerprints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

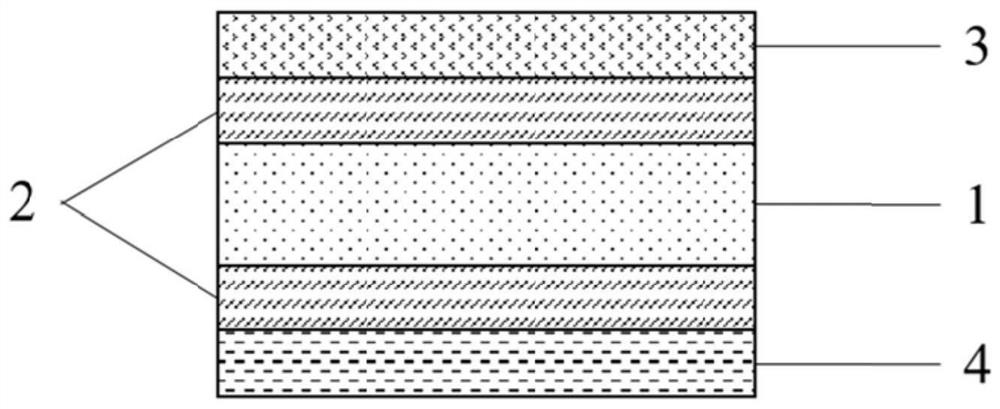

Image

Examples

Embodiment 1

[0048] The preparation method of the facing adhesive film paper of embodiment 1 anti-fingerprints, comprises the following steps:

[0049] 1) First gluing: impregnate the printed decorative base paper with urea-formaldehyde resin, the amount of impregnated resin per square meter of base paper is 80g, and then dry in three ovens (the temperature of the three ovens is set to 145°C, 160°C, and 150°C respectively) , to obtain the semi-finished printed decorative paper;

[0050] 2) Second gluing: Coat the back of the semi-finished printed decorative paper with melamine resin. The amount of melamine resin coated on the back of the semi-finished printed decorative paper per square meter is 40g, and the front is coated with melamine formaldehyde resin with matte function. The amount of melamine formaldehyde resin with matte function is coated on the front of the semi-finished printed decorative paper per square meter, and then dried in four ovens (the temperatures of the four ovens ar...

Embodiment 2

[0056] The preparation method of the facing adhesive film paper of embodiment 2 anti-fingerprints, comprises the following steps:

[0057] 1) First time gluing: impregnate the printed decorative base paper with melamine resin, the amount of impregnated resin per square meter of base paper is 70g, and then dry in three ovens (the temperature of the three ovens is set to 145°C, 160°C, 150°C respectively) , to obtain the semi-finished printed decorative paper;

[0058] 2) Second gluing: Coat the back of the semi-finished printed decorative paper with melamine resin. The amount of melamine resin coated on the back of the semi-finished printed decorative paper per square meter is 30g, and the front is coated with melamine formaldehyde resin with matte function. The amount of melamine formaldehyde resin with matte function is coated on the front of the semi-finished printed decorative paper per square meter, and then dried in four ovens (the temperatures of the four ovens are set to...

Embodiment 3

[0064] The preparation method of the facing adhesive film paper of embodiment 3 anti-fingerprints, comprises the following steps:

[0065] 1) First time gluing: impregnate the printed decorative base paper with urea-formaldehyde resin, the amount of impregnated resin per square meter of base paper is 90g, and then dry in three ovens (the temperature of the three ovens is set to 145°C, 160°C, and 150°C respectively) , to obtain the semi-finished printed decorative paper;

[0066] 2) Second gluing: Coat the back of the semi-finished printed decorative paper with melamine resin. The amount of melamine resin coated on the back of the semi-finished printed decorative paper per square meter is 50g, and the front is coated with melamine formaldehyde resin with a matte function. The amount of melamine-formaldehyde resin coated on the front of the semi-finished printed decorative paper per square meter is 10g, and then dried in four ovens (the temperatures of the four ovens are respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com