Glass etching liquid and method of etching glass therewith, cover glass and preparation method thereof

A technology of cover glass and etching solution, which is applied in the field of preparation of cover glass, etching glass, glass etching solution, cover glass and display equipment with the same, and can solve the problems that the preparation method of cover glass needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

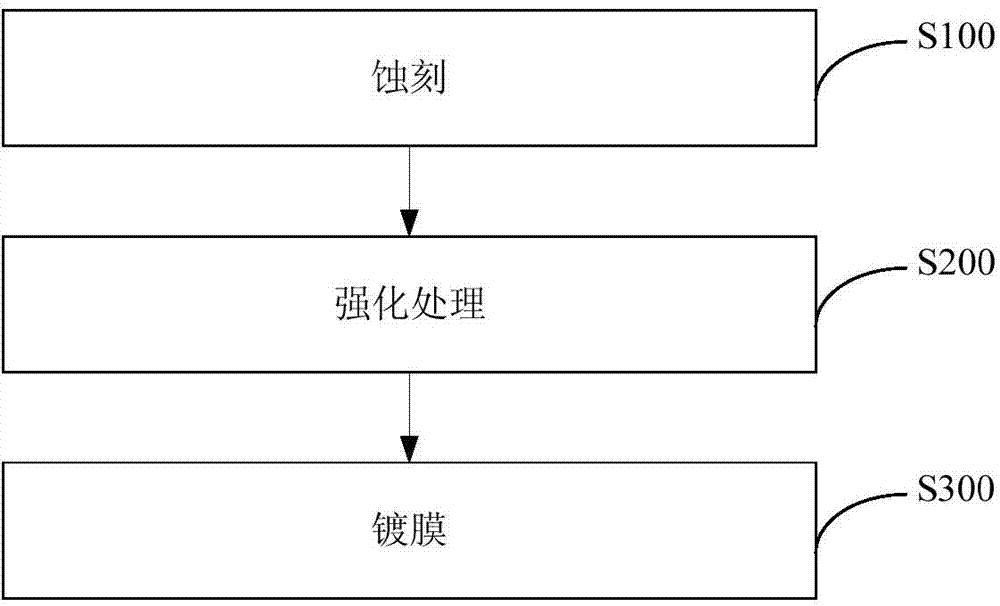

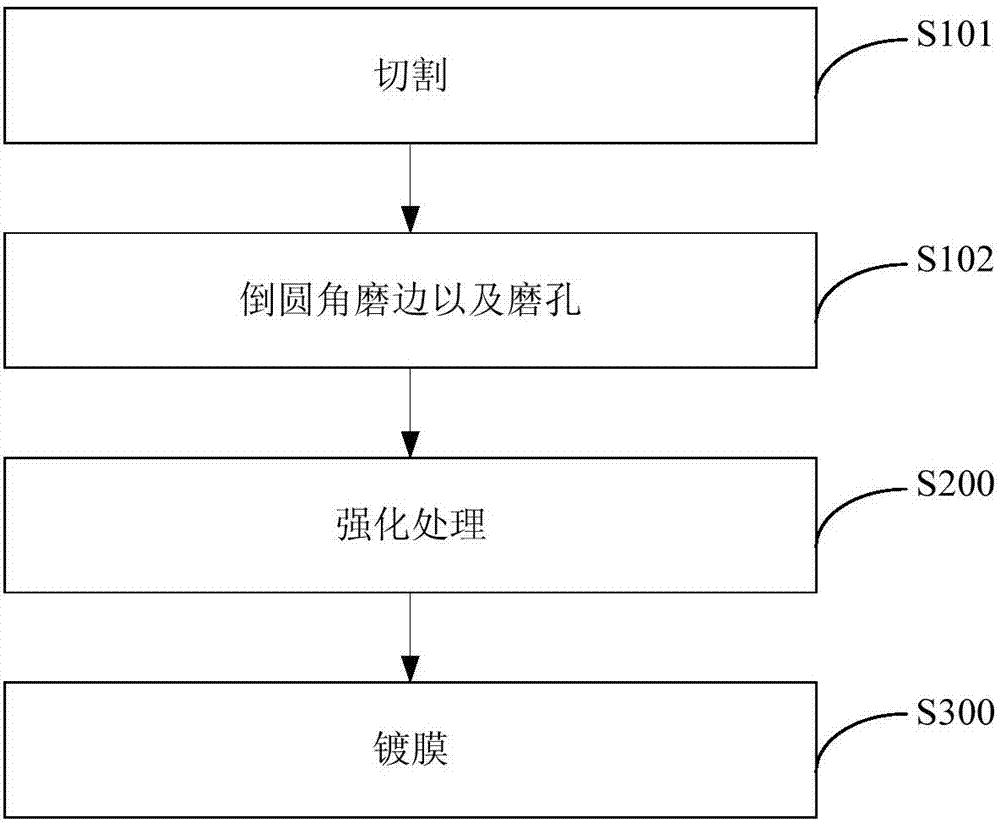

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of glass etching solution

[0033] Experimental raw materials and reagents: 10 parts by weight of ammonium fluoride, 0.01 parts by weight of sodium dodecylbenzenesulfonate, 15 parts by weight of sulfuric acid, 1 part by weight of potassium chloride, and 60 parts by weight of pure water.

[0034] Experimental procedure: Accurately weigh ammonium fluoride, sodium dodecyl sulfonate, sulfuric acid, potassium chloride and pure water according to the proportion, and then mix the above-mentioned raw materials and reagents obtained by weighing to obtain the glass etching solution 1.

Embodiment 2

[0035] Embodiment 2: the preparation of glass etching solution

[0036] Experimental raw materials and reagents: 10 parts by weight of ammonium fluoride, 0.05 parts by weight of sodium cetylbenzenesulfonate, 22 parts by weight of nitric acid, 3 parts by weight of potassium chloride, and 65 parts by weight of pure water.

[0037] Experimental procedure: Accurately weigh ammonium fluoride, sodium cetyl sulfonate, nitric acid, potassium chloride and pure water according to the proportion, and then mix the above-mentioned raw materials and reagents obtained by weighing to obtain the glass etching solution 2.

Embodiment 3

[0038] Embodiment 3: the preparation of glass etching solution

[0039] Experimental materials and reagents: 10 parts by weight of ammonium fluoride, 0.1 part by weight of sodium octadecyl sulfonate, 30 parts by weight of hydrochloric acid, 5 parts by weight of potassium chloride, and 70 parts by weight of pure water.

[0040] Experimental procedure: Accurately weigh ammonium fluoride, sodium octadecyl sulfonate, hydrochloric acid, potassium chloride and pure water according to the proportion, and then mix the above-mentioned raw materials and reagents obtained by weighing to obtain the glass etching solution 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface compressive stress | aaaaa | aaaaa |

| Four point bending strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com