A preparation method of anti-glare nano anti-microbial composite functional coating

An anti-microbial and composite function technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of glare, eye diseases, and visual health affecting workers' labor efficiency, and achieve good anti-glare and uniform coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

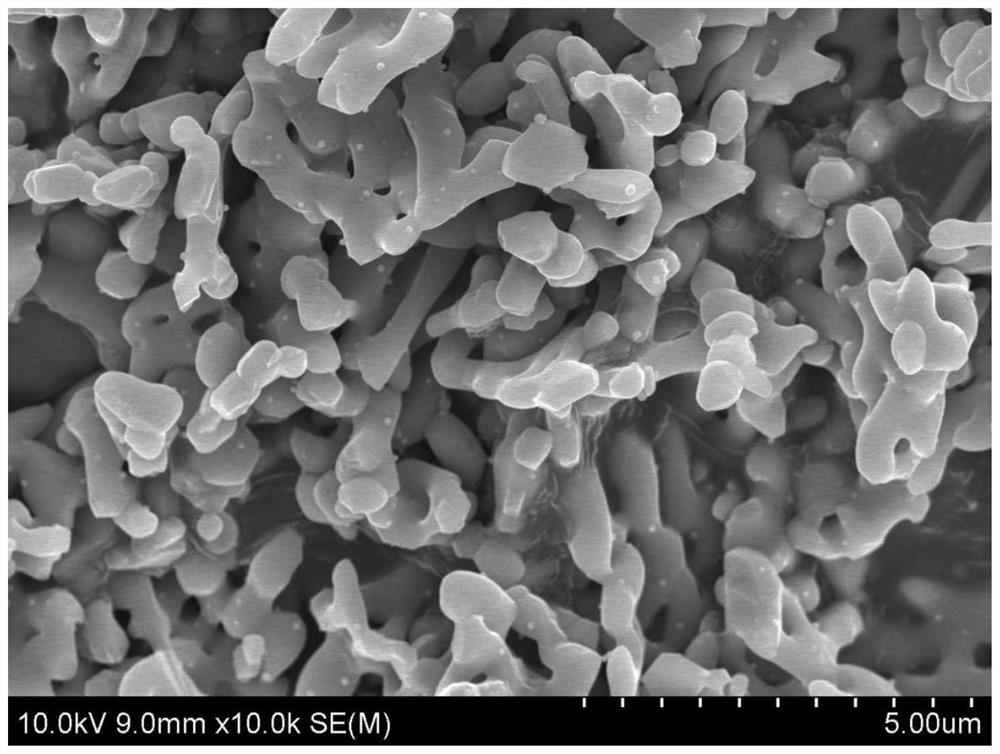

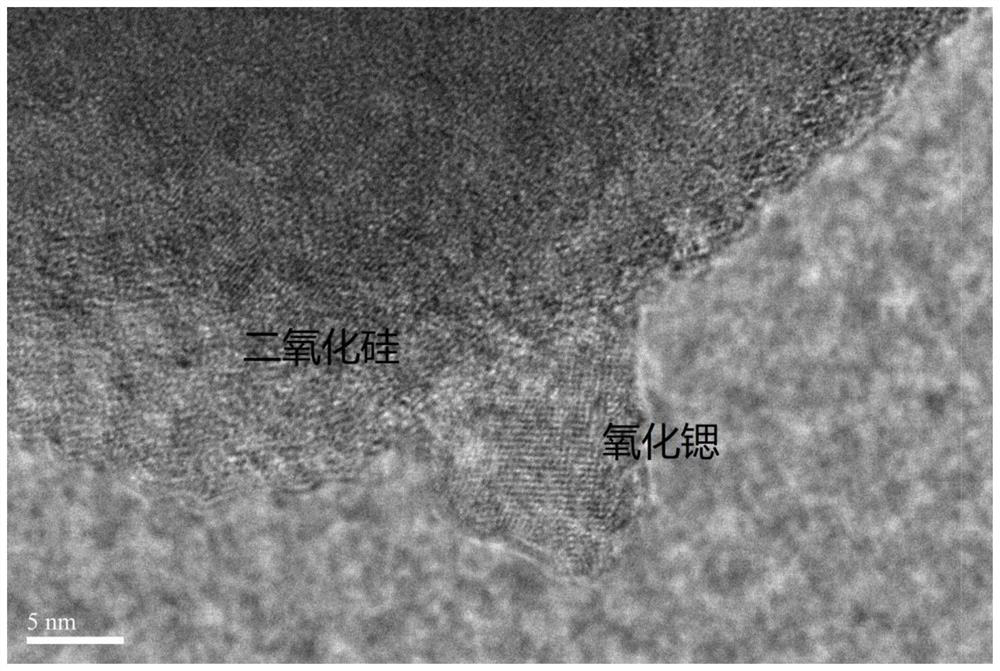

[0030] First prepare the silica particles with hemispherical strontium oxide enriched on the surface: add 10g of ethylenediaminetetraacetic acid, 5g of citric acid, and 1g of strontium citrate to 221g of water and stir evenly, add 663g of ethanol, then slowly add 100g of TEOS, drop Add concentrated ammonia water to adjust the pH value to 7, react at 30°C to form a gel, stir and mix with 100g of n-butanol, azeotropically distill at 92°C to remove the water, and continue to reflux to distill out n-butanol. The obtained precursor powder was treated at 400° C. for 2 h to obtain the desired hemispherical strontium oxide-enriched silica particles.

[0031] Dispersion modification of silica particles enriched in hemispherical strontium oxide: Take 2g of grinding resin EFKA-1101, 1g of wetting and dispersing agent ECO-2300, add them to 100g of ethanol solvent, stir evenly, add 10g of hemispherical strontium oxide enriched For silica particles, use an explosion-proof closed non-circula...

Embodiment 2

[0036] First prepare the silica particles with hemispherical strontium oxide enriched on the surface: add 14g ethylenediaminetetraacetic acid, 7g citric acid and 1.5g strontium acetate to 207g water and stir evenly, add 620g ethanol, then slowly add 150g TEOS, drop Add concentrated ammonia water to adjust the pH value to 8, react at 40°C to form a gel, stir and mix with 150g of n-butanol, azeotropically distill at 92°C to remove the water therein, and continue to reflux to distill out n-butanol. The obtained precursor powder was treated at 430° C. for 3 h to obtain the desired hemispherical strontium oxide-enriched silica particles.

[0037] Dispersion modification of hemispherical strontium oxide enriched silica particles: Take 2.4g of grinding resin EFKA-1120, 1.2g of wetting and dispersing agent byk110, add to 100g of propylene glycol methyl ether acetate solvent, stir well, add 10g of hemispherical The silicon dioxide particles enriched with strontium oxide are dispersed i...

Embodiment 3

[0042] First prepare the silica particles with hemispherical strontium oxide enriched on the surface: add 18g of ethylenediaminetetraacetic acid, 9g of citric acid, and 2g of strontium oxalate to 194g of water and stir evenly, add 583g of ethanol, then slowly add 180g of TEOS, drop Adjust the pH value to 8.5 with concentrated ammonia water, react at 45°C to form a gel, stir and mix with 180g of n-butanol, azeotropically distill at 92°C to remove the water, and continue to reflux to distill out n-butanol. The obtained precursor powder was treated at 480° C. for 4 h to obtain the desired hemispherical strontium oxide-enriched silica particles.

[0043] Dispersion modification of hemispherical strontium oxide enriched silica particles: Take 2.8g of grinding resin EFKA-1120, 1.4g of wetting and dispersing agent ECO-2300, add to 100g of propylene glycol methyl ether solvent, stir well, add 10g of hemispherical The silicon dioxide particles enriched with strontium oxide are disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

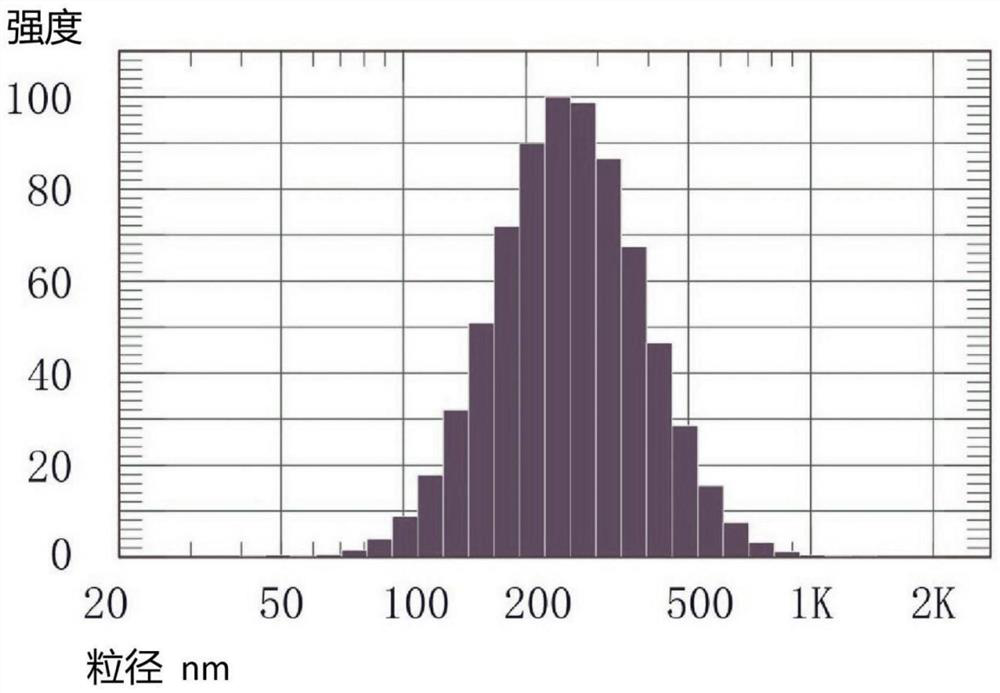

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com