Coating process of matte veneer

A coating process and veneer technology, which is applied to devices, coatings, special surfaces and other directions for coating liquid on the surface, which can solve the problems of poor surface effect, poor matte effect, and easy formation of particles and impurities. , to achieve the effect of good surface flatness, fast speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

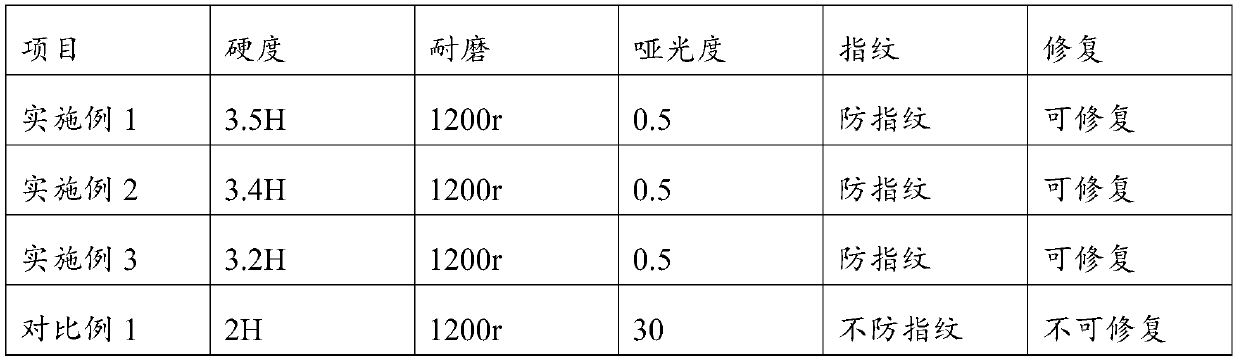

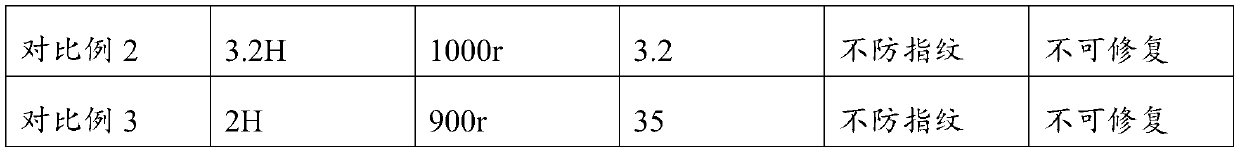

Examples

Embodiment 1

[0027] A coating process for a matte veneer, comprising the following steps:

[0028] (1) Clean the dust on the surface of the substrate, fill and seal the duct pores of the substrate with UV putty, and the coating amount is 44-46g / m 2 , put the UV putty at an energy of 150-200mJ / cm 2 Drying and curing under the environment, the duct pores of the substrate are filled and closed with UV putty paint for the second time, and the coating amount is 40-50g / m 2 , put the filled and sealed UV putty at an energy of 250-300mJ / cm 2 drying and curing;

[0029] (2) After filling and sealing, sand the surface of the UV putty, clean the dust on the surface of the board, and apply a UV sanding primer with a coating amount of 20-25g / m 2 , the direction of roller coating is two coats along the paint, and the UV sanding primer is applied at an energy of 250-300mJ / cm 2 drying and curing;

[0030] (3) Continue roller coating to make UV sanding primer. The direction of roller coating is one ti...

Embodiment 2

[0033] A coating process for a matte veneer, comprising the following steps:

[0034] (1) Clean the dust on the surface of the substrate, fill and seal the duct pores of the substrate with UV putty, and the coating amount is 40-50g / m 2 , put the UV putty at an energy of 150-200mJ / cm 2 Drying and curing under the environment, the duct pores of the substrate are filled and closed with UV putty paint for the second time, and the coating amount is 40-50g / m 2 , put the filled and sealed UV putty at an energy of 250-300mJ / cm 2 drying and curing;

[0035] (2) After filling and sealing, sand the surface of the UV putty, clean the dust on the surface of the board, and apply a UV sanding primer by roller coating. The coating amount should be controlled at 20-25g / m 2 , the direction of roller coating is two coats along the paint, and the UV sanding primer is applied at an energy of 250-300mJ / cm 2 drying and curing;

[0036] (3) Continue roller coating to make UV sanding primer. The ...

Embodiment 3

[0039] A coating process for a matte veneer, comprising the following steps:

[0040] (1) Clean the dust on the surface of the substrate, fill and seal the duct pores of the substrate with UV putty, and the coating amount is 40-50g / m 2 , dry and cure the UV putty;

[0041] (2) Roller coat UV sanding primer on the surface of UV putty. The direction of roller coating is to apply once along the direction, and then apply once in the opposite direction. The amount of coating is controlled at 25-30g / m 2 , at an energy of 280-300mJ / cm 2 drying and curing;

[0042] (3) Sand the surface of the UV sanding primer after drying and curing, remove the dust, and roll-coat the UV matte topcoat on the board surface, and the coating amount of the UV matte topcoat is controlled at 30-40g / m 2, and then enter the ultra-matt matting machine for matting. The nitrogen inlet pressure of the ultra-matting matting machine is controlled at 7bar, the nitrogen purity is ≧99%, the temperature must not be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com