Photocatalytic compound exhaust gas treatment system

A waste gas treatment and composite technology, which is applied in the direction of combined devices, gasification substances, chemical instruments and methods, etc., can solve problems such as conflicts of energy saving and consumption reduction, limited use, easy cracking of pipes, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

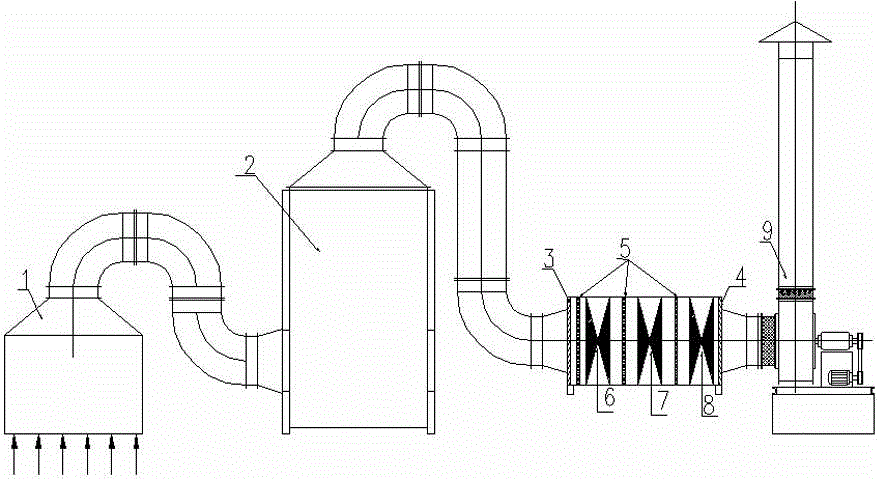

[0019] The present invention as figure 1 shown.

[0020] A photocatalytic composite exhaust gas treatment system, comprising an exhaust gas collection cover 1, the exhaust gas collection cover 1 is connected with a spray tower 2, the spray tower 2 is connected with a photo-oxygen catalytic device, and the photo-oxygen catalytic device is connected with an induction Wind device 9; filter 3 through the first filter screen between the photo-oxygen catalytic device and the spray tower 2, and filter through the second filter screen 4 between the photo-oxygen catalytic device and the draft device 9; Multi-channel TiO2 filter screen, UVC tube and ozone generator, wherein the multi-channel TiO2 filter screen 5 and UVC tube and ozone generator are arranged at intervals.

[0021] There are three TiO2 filter screens 5, UVC tubes and ozone generators, wherein the TiO2 filter screens are set behind the first filter screen, and then the first UVC tube and ozone generator 6, TiO2 filter scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com