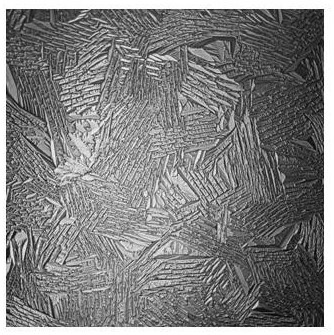

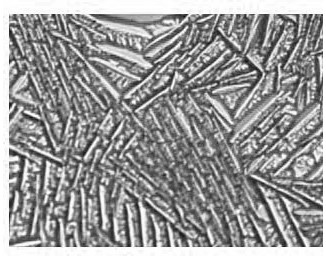

Glass etching liquid simulating rock bedding staggered stacking effect and glass manufacturing process

A production process, rock imitation technology, applied in the field of glass production, to achieve uniform size, excellent effect, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] ①. Prepare the etching solution for imitating rock bedding lines according to the following formula (wt%): NH 4 HF 2 16.5%, NH 4 F7.5%, ALF 3 3.5%, HNO 3 18%, H 3 PO 4 6%, H 2 SO 4 11.5%, (NH 4 ) 2 SiF 6 4.5%, BaSO 4 3.5%, KCL2.5%, V 2 O 5 0.2%, Sodium Alkylbenzene Sulfonate 0.3%, Sorbitol 3.8%, H 2 O 22.2%.

[0037] ②. Put the prepared etching liquid in a stirring container for full stirring until the liquid is in a uniform state of supersaturated solution, and let it stand and mature for 72 hours.

[0038] ③ After the curing time is completed, stir again before use.

[0039] ④. Protect the back of the cleaned glass sheet with film, and put it into the chemical solution for etching.

[0040] ⑤. The original glass sheet placed in the liquid medicine swings according to the figure-8 trajectory, the swing speed is controlled at 40 laps / min, and the swing amplitude is controlled at 400MM.

[0041] ⑥, the swing time is controlled at 3.5 minutes.

...

example 1

[0043] Example 1 Product performance test data: gloss 15.8%, light transmittance 25.6%, haze 69.5%, roughness 1.2 μm, reflectance 6.8%.

Embodiment 2

[0045] ①. Prepare the etching solution for imitating rock bedding lines according to the following formula (wt%): NH 4 HF 2 19.5%, NH 4 F4.5%, ALF 3 5.5%, HNO 3 15.5%, H 3 PO 4 9%, H 2 SO 4 10.5%, (NH 4 ) 2 SiF 6 3%, BaSO 4 2.5%, KCL3.5%, V 2 O 5 0.2%, Sodium Alkylbenzene Sulfonate 0.5%, Sorbitol 4.5%, H 2 O 21.3%.

[0046] ②. Put the prepared etching liquid in a stirring container for full stirring until the liquid is in a uniform state of supersaturated solution, and let it stand and mature for 72 hours.

[0047] ③ After the curing time is completed, stir again before use.

[0048] ④. Protect the back of the cleaned glass sheet with film, and put it into the chemical solution for etching.

[0049] ⑤. The original glass sheet placed in the liquid medicine swings according to the figure-8 trajectory, the swing speed is controlled at 60 laps / min, and the swing amplitude is controlled at 450MM.

[0050] ⑥, the swing time is controlled at 4.5 minutes.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com