Silicon-zirconium composite super-hydrophilic abrasion-resistant coating

A wear-resistant coating and silicon-zirconium composite technology, applied in the coating field, can solve the problems of wear resistance, scratch resistance, anti-fingerprint, poor stain resistance, short service life of super-hydrophilic coating, low coating hardness, etc. problems, to achieve the effects of good water resistance and weather resistance, good anti-fog performance, and high pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

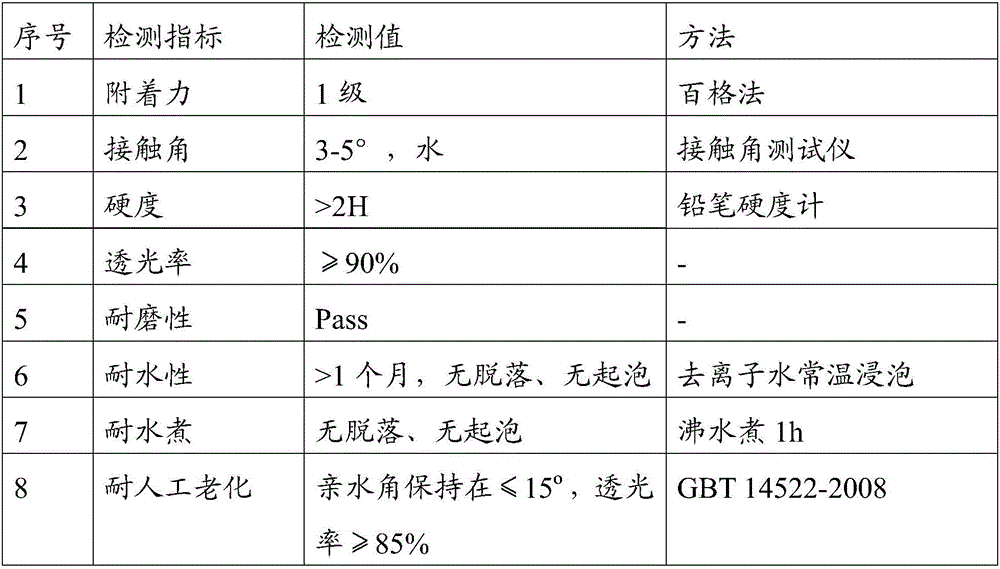

Embodiment 1

[0035] The silicon-zirconium composite super-hydrophilic wear-resistant coating of the present invention comprises the following components by weight: 10 grams of single-layer zirconium hydrogen phosphate, 30 grams of silica sol containing sulfonic acid groups, and 30 grams of silane coupling agent , 50 grams of alcohol solvent. Wherein, the silane coupling agent is methyltriethoxysilane, and the alcohol solvent is ethanol.

[0036] The single-layer zirconium hydrogen phosphate is prepared by the following method: 20 grams of α-zirconium hydrogen phosphate is ultrasonically peeled off with 100 ml of 0.1 mol / liter propylamine solution, and 110 ml of 0.1 mol / liter hydrochloric acid is added to replace and remove the propylamine, and then water Excess hydrochloric acid was washed alternately with ethanol to obtain monolayer zirconium hydrogen phosphate.

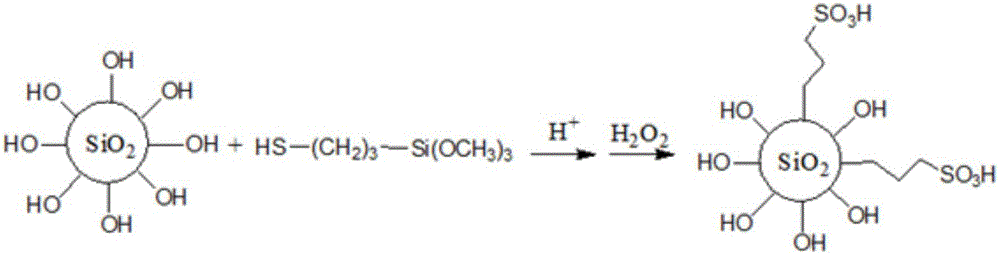

[0037] The preparation method of the silica sol containing sulfonic acid group is: 40 grams of nano-scale silica sol are stir...

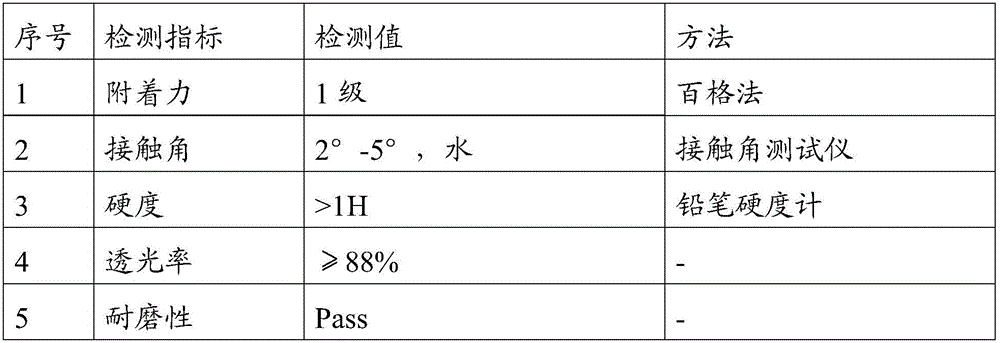

Embodiment 2

[0044]The silicon-zirconium composite super-hydrophilic wear-resistant coating of the present invention comprises the following components by weight: 30 grams of single-layer zirconium hydrogen phosphate, 50 grams of silica sol containing sulfonic acid groups, and 25 grams of silane coupling agent , 60 grams of alcohol solvent. Wherein, the silane coupling agent is a mixture of γ-mercaptopropyl tetraethoxysilane and γ-mercaptopropyl tetramethoxysilane in a mass ratio of 1:1, and the alcohol solvent is isopropanol.

[0045] Single-layer zirconium hydrogen phosphate is prepared by the following method: 40 grams of α-zirconium hydrogen phosphate is ultrasonically peeled off with 300 milliliters of 0.1 mol / liter propylamine solution, and 280 milliliters of 0.1 mol / liter hydrochloric acid is added to replace and remove propylamine, and then water Excess hydrochloric acid was washed alternately with ethanol to obtain monolayer zirconium hydrogen phosphate.

[0046] The preparation ...

Embodiment 3

[0054] The silicon-zirconium composite super-hydrophilic wear-resistant coating of the present invention comprises the following components by weight: 5 grams of single-layer zirconium hydrogen phosphate, 10 grams of silica sol containing sulfonic acid groups, and 20 grams of silane coupling agent , 30 grams of alcohol solvent. Wherein, the silane coupling agent is γ-mercaptopropylmethyltrimethoxysilane, and the alcohol solvent is propylene glycol methyl ether acetate.

[0055] The single-layer zirconium hydrogen phosphate is prepared by the following method: 10 grams of α-zirconium hydrogen phosphate is ultrasonically peeled off with 200 ml of 0.1 mol / liter propylamine solution, and 120 ml of 0.1 mol / liter hydrochloric acid is added to replace and remove the propylamine, and then water Excess hydrochloric acid was washed alternately with ethanol to obtain monolayer zirconium hydrogen phosphate.

[0056] The preparation method of the silica sol containing sulfonic acid group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com