Method and system for manufacturing multi-layer composite paint-free molded three-dimensional board

A multi-layer composite and manufacturing method technology, applied in the field of building materials manufacturing, can solve the problems of easy cracking of the decorative surface layer, high production cost, heavy pollution, etc., and achieve the effect of solving surface layer cracking, solving quality defects, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

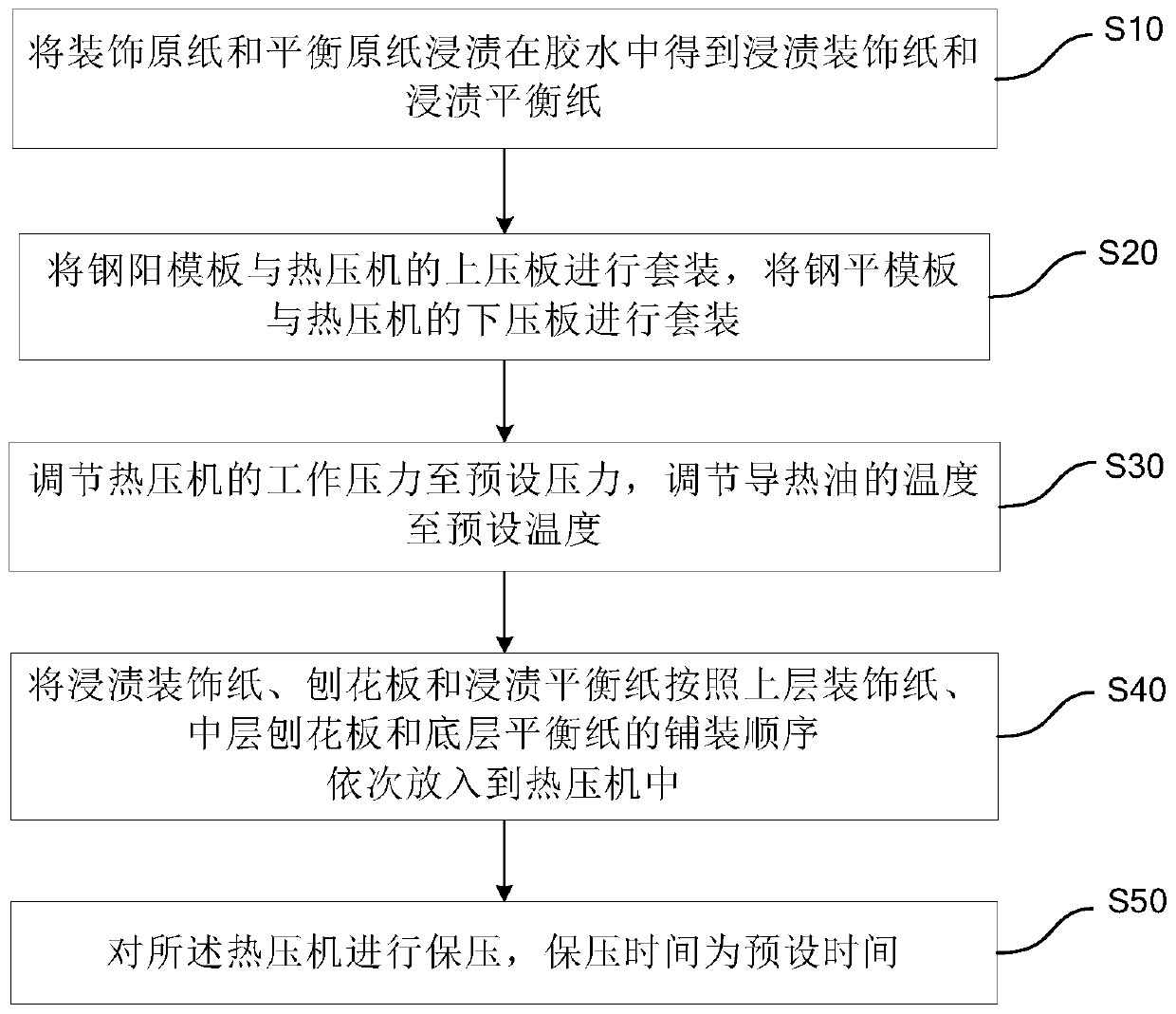

[0031] This embodiment discloses a specific embodiment of a method for manufacturing a multi-layer composite paint-free molded three-dimensional panel, including steps:

[0032] S10: impregnating the decorative base paper and the balance base paper in glue to obtain an impregnated decorative paper and an impregnated balance paper;

[0033] S20: Assemble the steel positive formwork with the upper platen of the hot press, and set the steel flat formwork with the lower platen of the heat press;

[0034] S30: adjusting the working pressure of the heat press to a preset pressure, and adjusting the temperature of the heat transfer oil to a preset temperature;

[0035] S40: Put the impregnated decorative paper, the particle board and the impregnated balancing paper into the heat press in sequence according to the laying sequence of the upper layer of decorative paper, the middle layer of particle board and the bottom layer of balancing paper;

[0036] S50: maintaining pressure on th...

Embodiment 2

[0038] This embodiment discloses another specific embodiment of the method for manufacturing a multi-layer composite paint-free molded three-dimensional board, the steps of which are basically the same as those in Embodiment 1, the difference being that in step S10 of the method of this embodiment, dipping Decorative and impregnated balance papers had a volatile content of 7.5% and a precure of 45%.

[0039] Specifically, in step S20, the thickness of the steel male formwork and the rigid flat formwork are both 7.5mm, the height of the convex pattern of the steel male formwork is 5% of the thickness of the particleboard, and the width of the positive pattern is 1 / 4 of the height of the positive pattern. 20 times, the top arc radius of the positive pattern is 35 times the height of the positive pattern, the transition radius of the positive pattern is 20 times the height, the positive pattern is treated with high light, and the gloss of the positive pattern is 180 degrees.

[0...

Embodiment 3

[0043] This embodiment discloses another specific embodiment of the method for manufacturing a multi-layer composite paint-free molded three-dimensional board, the steps of which are basically the same as those in Embodiment 1, the difference being that in step S10 of the method of this embodiment, dipping The decorative paper and impregnated balance paper had a volatile content of 7.7% and a pre-cured degree of 46%.

[0044] Specifically, in step S20, the thickness of the steel male template and the rigid flat template are both 8mm, the height of the convex pattern of the steel male template is 6% of the thickness of the particleboard, and the width of the male pattern is 23% of the height of the male pattern. times, the radius of the top arc of the sun pattern is 38 times the height of the sun pattern, the transition radius of the sun pattern is 22 times the height, the sun pattern has been treated with high light, and the gloss of the sun pattern is 186 degrees.

[0045] Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com