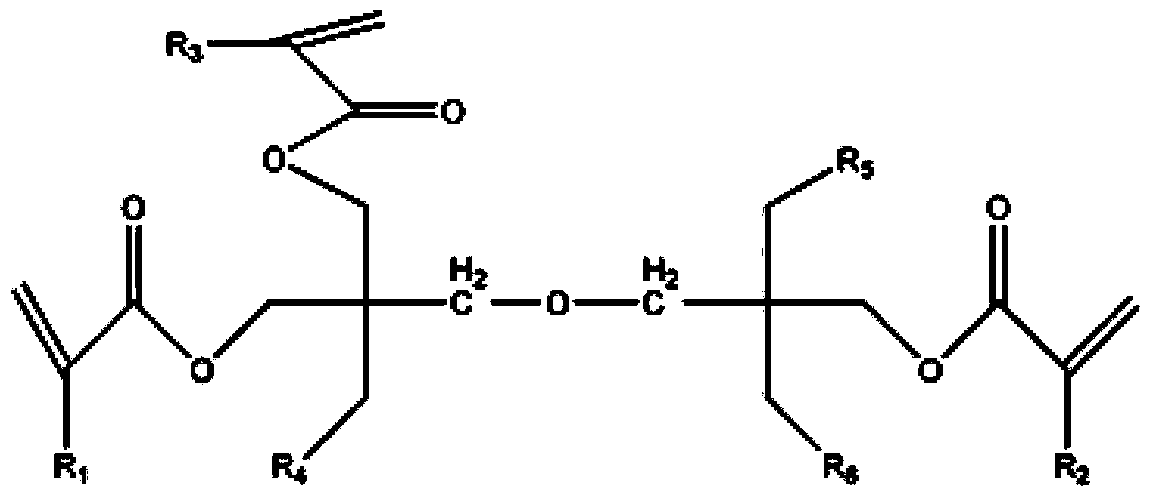

Low-viscosity high-reactivity low-volume-contraction modified dipentaerythritol acrylate and preparation method thereof

A high-reactivity, dipentaerythritol technology, applied in the preparation of organic compounds, the preparation of carbamate derivatives, chemical instruments and methods, etc., can solve the adverse effects on the environment and human health, product volatile migration, high volume shrinkage, etc. problems, to achieve the effect of improving light curing efficiency, increasing light curing rate, and low volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

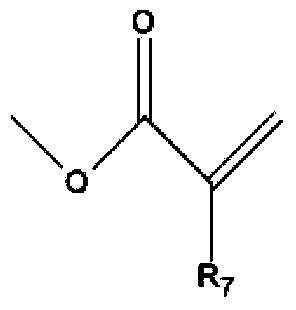

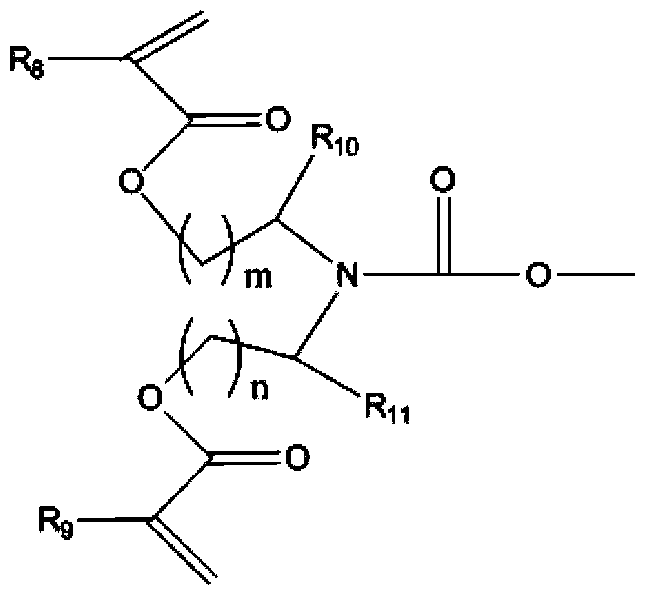

Method used

Image

Examples

Embodiment 1

[0057] Preparation of cyclic 1,3 propanediol carbonate-type modified dipentaerythritol from dipentaerythritol and dimethyl carbonate:

[0058] Add (127 g, 0.5 mol) dipentaerythritol, (180 g, 2 mol) dimethyl carbonate and (0.56 g, 5 mmol) 1,4-diazabicyclo[2.2.2]octane DABCO into a In a 2000ml reaction flask with a reflux condenser, place the flask in a sand bath in an electric heating mantle, use a temperature controller connected to a thermocouple immersed in the sand bath to control the temperature of the sand bath, use the sand bath to heat the contents of the solution in the flask with stirring To 80 ℃, by stirring, the solid component of the solution in the flask dissolves into a colorless transparent solution, the reaction temperature is maintained at 80 ℃ and continues to stir for 14 hours; the reaction product methanol is continuously distilled out during the reaction, and the excess dicarbonate The methyl ester was distilled out of the reaction bottle, and the remainin...

Embodiment 2

[0060] The cyclic 1,3 propanediol carbonate type modified dipentaerythritol and the diethanolamine reaction synthesis band tertiary amine modified dipentaerythritol polyols by the gained of embodiment 1:

[0061] Before cooling the reaction product in the flask of Example 1 to room temperature, add (105g, 1mol) diethanolamine and 600ml cyclohexane, under the action of electric stirring, the solution in the flask is slowly heated to 70°C, and the reaction temperature is maintained at 70°C Continue to stir for 3 hours, cool to room temperature after the reaction is over, do multiple experiments at the same time under the same conditions as above, one of the obtained products is purified by ethanol and water precipitation, recrystallization, etc., and is separated by silica gel chromatography (n-hexane: acetic acid Ethyl ester=4:1), the rest of the resulting product is not further processed as the raw material for the next step; the purified product is subjected to FTIR infrared a...

Embodiment 3

[0063] The cyclic 1,3 propanediol carbonate type modified dipentaerythritol and the diisopropanolamine reaction synthesis band tertiary amine modified dipentaerythritol polyol by embodiment 1 gained:

[0064] Before cooling the reaction product in the flask of Example 1 to room temperature, (133g, 1mol) diisopropanolamine and 600ml cyclohexane were added, and under the action of electric stirring, the solution in the flask was slowly heated to 70°C, and the reaction temperature was maintained Stirring was continued at 70 ° C for 3 h, and cooled to room temperature after the reaction was completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com