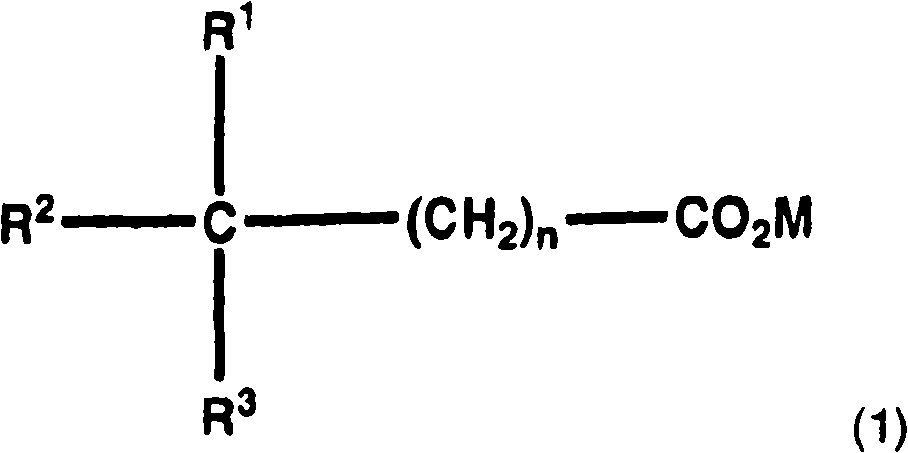

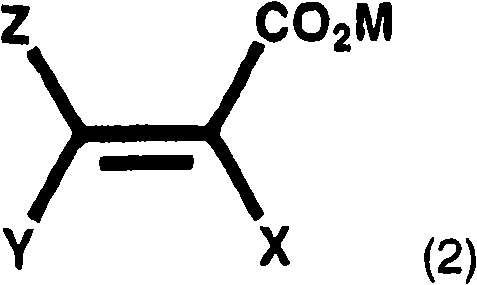

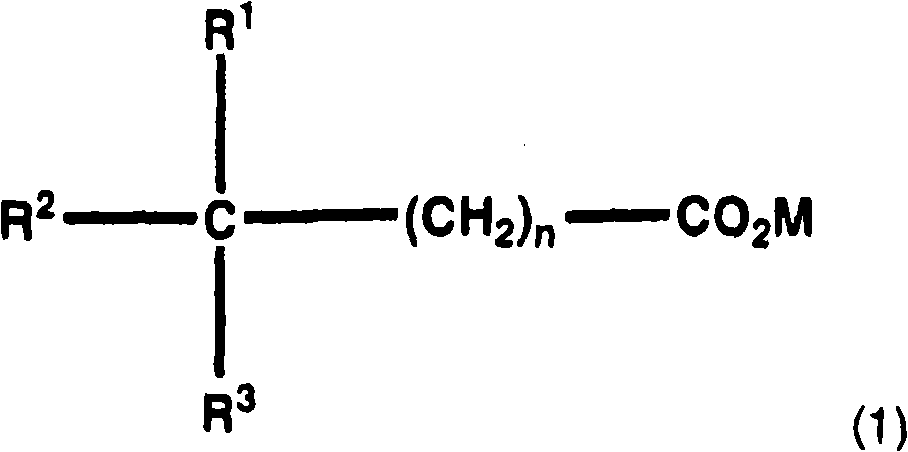

Tetraalkylammonium carboxylate salts as trimerization catalysts for spray foam applications

A technology of foam plastics and blowing agents, which is applied in the field of preparing PIR/PUR spray foam plastics, can solve problems such as instability, and achieve the effects of good performance, minimized surface brittleness, and fast surface curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] In a 32-ounce (951 ml) metal cup, the catalyst according to the present invention was added to a foam composition (Table 1) to make foam, wherein the foam composition contained polyisocyanate (crude MDI), polybasic alcohol, flame retardant (TCPP), surfactant, urethane catalyst ( 5 catalyst) and blowing agent (n-pentane). The composition was mixed at about 6,000 RPM for about 10 second(s) using an overhead mixer equipped with a 2 inch (5.1 cm) diameter impeller. Sufficient MDI isocyanate was then added to achieve an isocyanate index of 270, and the formulation was mixed well for about 6 seconds at about 6,000 RPM using the same mixer. The 32-ounce (951 ml) cup was dropped onto a stand through the hole in the bottom of the 128-ounce (3804 ml) paper cup. The hole is sized to catch the lip of a 32oz (951ml) mug. The total volume of the foam container was about 160 ounces (4755 ml). The foam is approximately this volume at the end of the foam forming reaction. Record t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com