High-sun-resistance printing ink for impregnated paper and preparation method of high-sun-resistance printing ink

A printing ink and high light fastness technology, applied in the field of printing ink, can solve the problems of graphic ink layer losing luster, unfavorable ink printing, yellowing and whitening of ink, etc., to achieve surface curing, not easy to yellow, aging, change The effect of rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

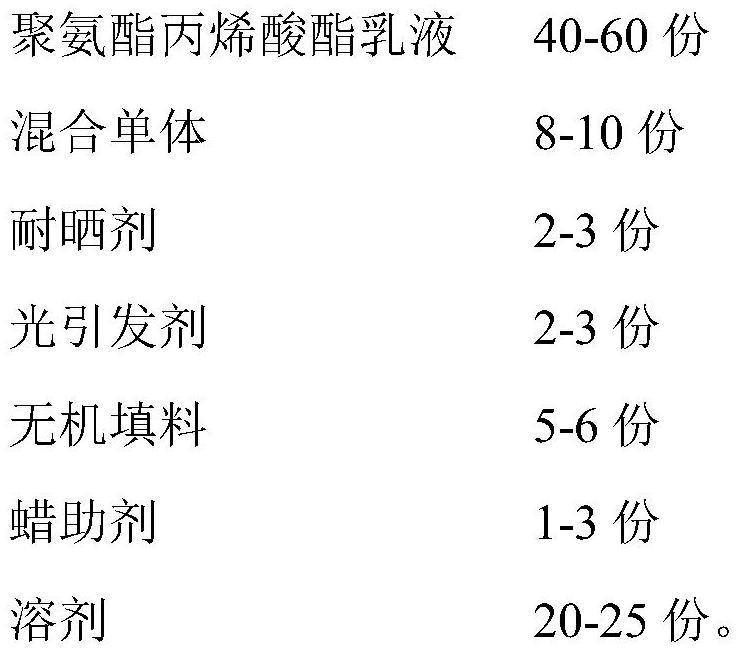

[0036] A high light fast printing ink for impregnated paper, comprising the following raw materials in parts by weight:

[0037]

[0038]

[0039] Described polyurethane acrylate emulsion is made through the following steps:

[0040] Step A: In parts by weight, take 10 parts of polyurethane prepolymer, 6 parts of methyl methacrylate, 5 parts of isooctyl acrylate, 0.5 part of methacrylic acid, 1 part of emulsifier and 18 parts of deionized water, and homogenize Stir evenly to obtain a precursor;

[0041] Step B: The temperature of the precursor prepared in step A is raised to 80° C., and then 1 part of initiator is added while stirring. After the addition is completed, heat preservation treatment is carried out to obtain a polyurethane acrylate emulsion.

[0042] In the step A, the emulsifier is a mixture of sodium alkyl diphenyl ether disulfonate and nonylphenol polyoxyethylene ether with a weight ratio of 1:1.5; the homogeneous stirring speed is 1200rpm, and the homoge...

Embodiment 2

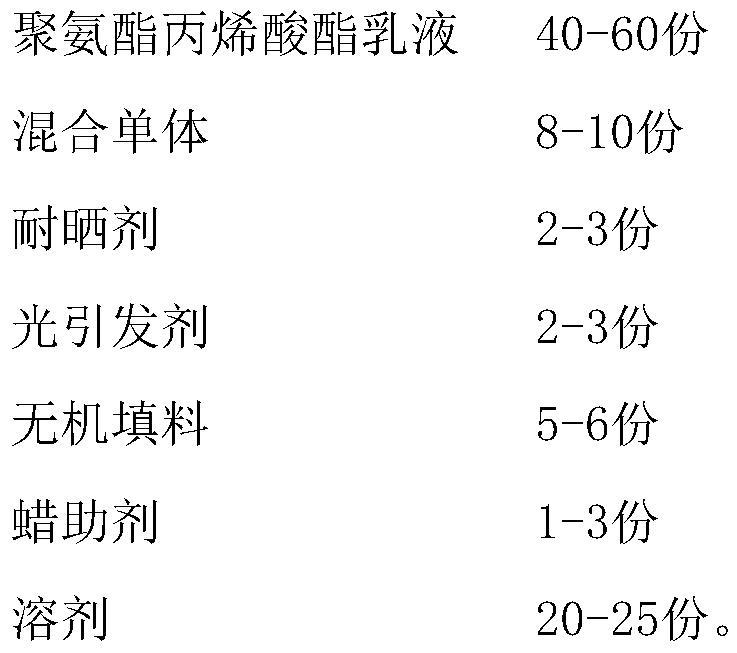

[0054] A high light fast printing ink for impregnated paper, comprising the following raw materials in parts by weight:

[0055]

[0056] Described polyurethane acrylate emulsion is made through the following steps:

[0057] Step A: In parts by weight, take 11 parts of polyurethane prepolymer, 7 parts of methyl methacrylate, 7 parts of isooctyl acrylate, 0.8 part of methacrylic acid, 2 parts of emulsifier and 19 parts of deionized water, homogenize Stir evenly to obtain a precursor;

[0058] Step B: The temperature of the precursor prepared in step A was raised to 82° C., and then 1.5 parts of initiator was added while stirring. After the addition was completed, heat preservation treatment was carried out to obtain a polyurethane acrylate emulsion.

[0059] In the step A, the emulsifier is a mixture of sodium alkyl diphenyl ether disulfonate and nonylphenol polyoxyethylene ether with a weight ratio of 1:2.0; the homogeneous stirring speed is 1300rpm, and the homogeneous du...

Embodiment 3

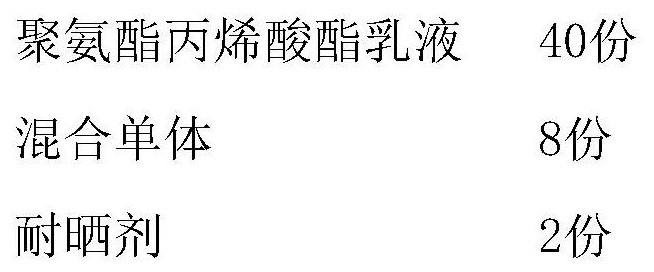

[0071] A high light fast printing ink for impregnated paper, comprising the following raw materials in parts by weight:

[0072]

[0073] Described polyurethane acrylate emulsion is made through the following steps:

[0074] Step A: In parts by weight, take 13 parts of polyurethane prepolymer, 8 parts of methyl methacrylate, 8 parts of isooctyl acrylate, 1.0 part of methacrylic acid, 3 parts of emulsifier and 20 parts of deionized water, homogenize Stir evenly to obtain a precursor;

[0075] Step B: The temperature of the precursor prepared in step A was raised to 83° C., and then 2 parts of initiator were added while stirring. After the addition was completed, the polyurethane acrylate emulsion was prepared by heat preservation treatment.

[0076] In the step A, the emulsifier is a mixture of sodium alkyl diphenyl ether disulfonate and nonylphenol polyoxyethylene ether with a weight ratio of 1:2.5; the homogeneous stirring speed is 1500rpm, and the homogeneous duration is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com