Method for improving UV ink-jet printing efficiency and quality

An inkjet printing and high-efficiency technology, applied in the field of light curing, can solve the problems of heavy graininess, inability to achieve image effects, and difficult curing, etc., and achieve the effects of improved printing efficiency and quality, good surface curing, and clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

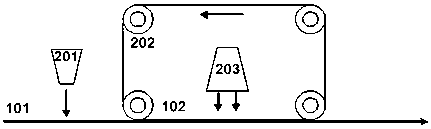

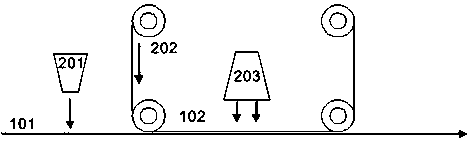

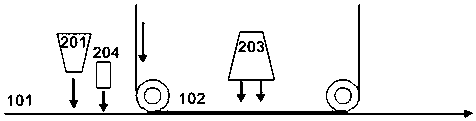

Image

Examples

Embodiment 1

[0023] A method to improve the efficiency and quality of UV inkjet printing. After the UV inkjet unit, cover the surface of the printing pattern with a transparent film, then perform UV curing, and then peel off the transparent film to obtain a smooth printing pattern.

[0024] The light transmittance of the transparent film in the ultraviolet region is greater than 80%.

[0025] The light transmittance of the transparent film in the ultraviolet region is greater than 90%.

[0026] The transparent film is PET, PC, PP, PE or PVC.

[0027] The side of the transparent film covering the printing pattern is coated with a release agent, so that the transparent film and the UV inkjet ink are not easy to stick, and can be completely peeled off after the UV ink is cured, improving the peeling performance of the transparent film, so that the transparent film can be recycled. , that is, after covering, curing, and stripping procedures, it can be used again. The recycling of transparent...

Embodiment 2

[0032] A method to improve the efficiency and quality of UV inkjet printing. After the UV inkjet unit, cover the surface of the printing pattern with a transparent film, then perform UV curing, and then peel off the transparent film to obtain a smooth printing pattern. The light transmittance of the transparent film in the ultraviolet region is 82%, and the transparent film is PET.

Embodiment 3

[0034] A method to improve the efficiency and quality of UV inkjet printing. After the UV inkjet unit, cover the surface of the printing pattern with a transparent film, then perform UV curing, and then peel off the transparent film to obtain a smooth printing pattern. The light transmittance of the transparent film in the ultraviolet region is 85%. The transparent film is PC, and the side of the transparent film covering the printing pattern is coated with a release agent. In this way, the transparent film and the UV inkjet ink are not easy to adhere. It can be completely peeled off after curing, improving the peeling performance of transparent films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com