Photoinitiator as well as preparation method and application thereof

A photoinitiator and integer technology, which is applied in the field of photoinitiator and its preparation, can solve the problems of UVLED output wavelength mismatch, increase the content of surface photoinitiator, and low refractive index of the cured film surface, so as to promote surface coating curing, The effect of good photosensitivity and excellent photopolymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

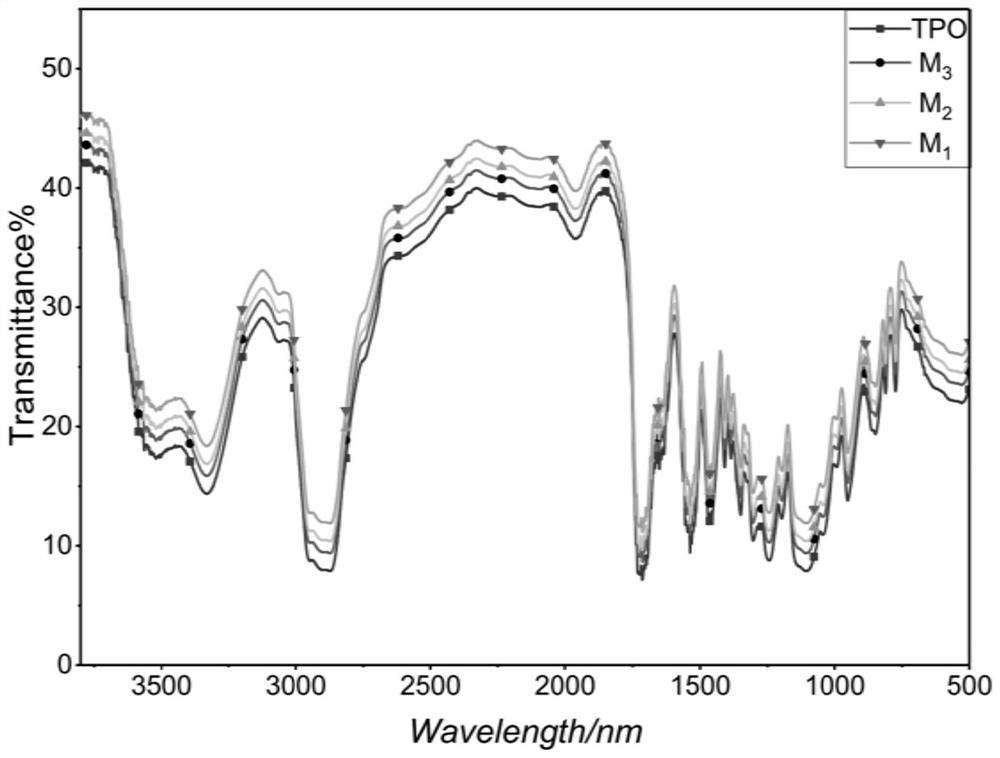

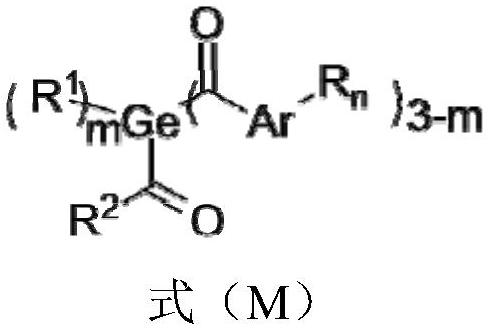

[0064] The present embodiment provides a kind of photoinitiator, has such as formula (M 1 ) shows the structure:

[0065]

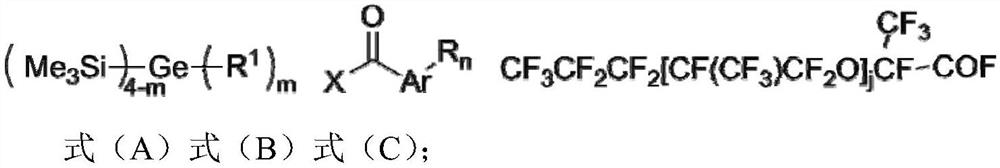

[0066] Nitrogen atmosphere, room temperature, dark conditions, (Me 3 Si) 2 Ge(CH 3 ) 2 (A 1 , 2.50g, 0.01mol) was dissolved in 50ml of toluene solution, KOtBu (1.2g, 0.011mol) toluene solution was added dropwise, and stirred at room temperature for 2h. Then dropwise add p-methoxybenzoyl fluoride (B 1 , 1.70g, 0.011mol) toluene solution, placed at room temperature and stirred for 4h; then added dropwise perfluoropolyether acid fluoride compound (C 1 , j=6, 12.16g, 0.01mol) toluene solution, and continue to react at room temperature for 8h. Extract and wash with 3% sulfuric acid aqueous solution for 3 times, then dry with anhydrous sodium sulfate to remove water, and distill off the solvent under reduced pressure to obtain compound M 1 crude product. The crude product was recrystallized with acetone solution to obtain light yellow powder compoun...

Embodiment 2

[0071] The present embodiment provides a kind of photoinitiator, has such as formula (M 2 ) shows the structure:

[0072]

[0073] Nitrogen atmosphere, room temperature, dark conditions, (Me 3 Si) 3 GCH 3 (A 2 , 3.08g, 0.01mol) was dissolved in 50ml ethylene glycol dimethyl ether solution, KOtBu (1.2g, 0.011mol) ethylene glycol dimethyl ether solution was added dropwise, and stirred at room temperature for 2h. Then p-toluyl chloride (B 2 , 3.24g, 0.021mol) ethylene glycol dimethyl ether solution, placed at room temperature and stirred for 4h; then added dropwise perfluoropolyether acyl fluoride (C 2 , j=8, 15.48g, 0.01mol) ethylene glycol dimethyl ether solution, and continue to react at room temperature for 8h. Extract and wash with 3% sulfuric acid aqueous solution for 3 times, then dry with anhydrous sodium sulfate to remove water, and distill off the solvent under reduced pressure to obtain compound M 2 crude product. The crude product was recrystallized with ac...

Embodiment 3

[0078] The present embodiment provides a kind of photoinitiator, has such as formula (M 3 ) shows the structure:

[0079]

[0080] Nitrogen atmosphere, room temperature, dark conditions, (Me 3 Si) 4 Ge(A 3 , 3.66g, 0.01mol) was dissolved in 50ml ethylene glycol dimethyl ether solution, KOtBu (1.2g, 0.011mol) ethylene glycol dimethyl ether solution was added dropwise, and stirred at room temperature for 2h. Then add benzoyl bromide (B 3 , 5.70g, 0.031mol) ethylene glycol dimethyl ether solution, placed at room temperature and stirred for 5h; then added dropwise perfluoropolyether acyl fluoride (C 3 , j=12, 23.24g, 0.01mol) ethylene glycol dimethyl ether solution, and continue to react at room temperature for 8h. Extract and wash with 3% sulfuric acid aqueous solution for 3 times, then dry with anhydrous sodium sulfate to remove water, and distill off the solvent under reduced pressure to obtain compound M 3 crude product. The crude product was recrystallized with acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com