Anti-reflection anti-reflection transparent conductive film

A technology of transparent conductive film and anti-reflection and anti-reflection technology, which is applied in the direction of electrical digital data processing, instrument, input/output process of data processing, etc. Control process requirements are very harsh and other issues, to achieve the effect of reducing production costs and easy control of the disappearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

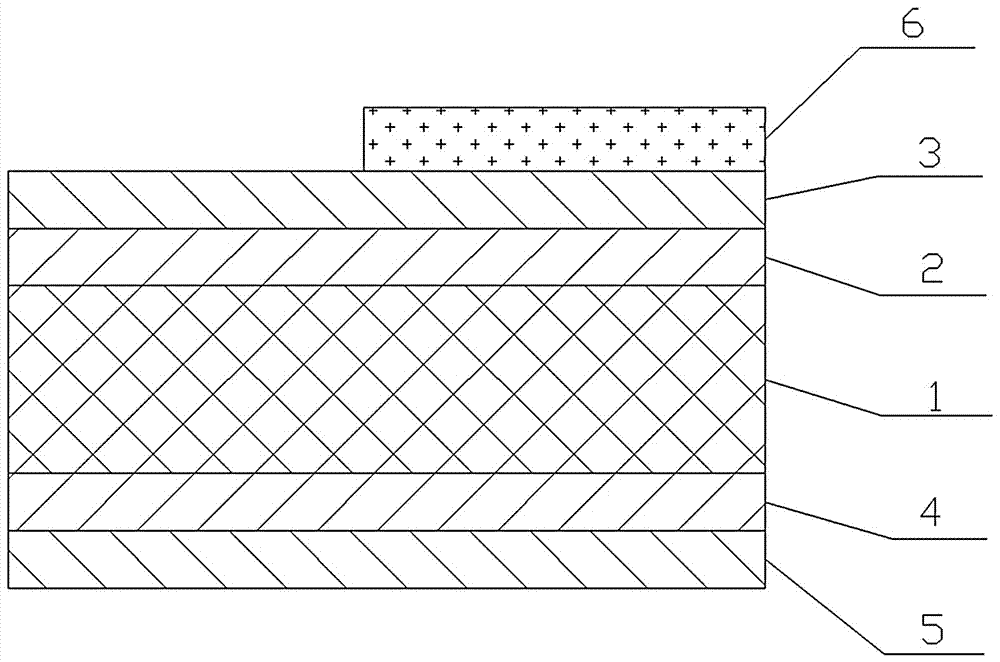

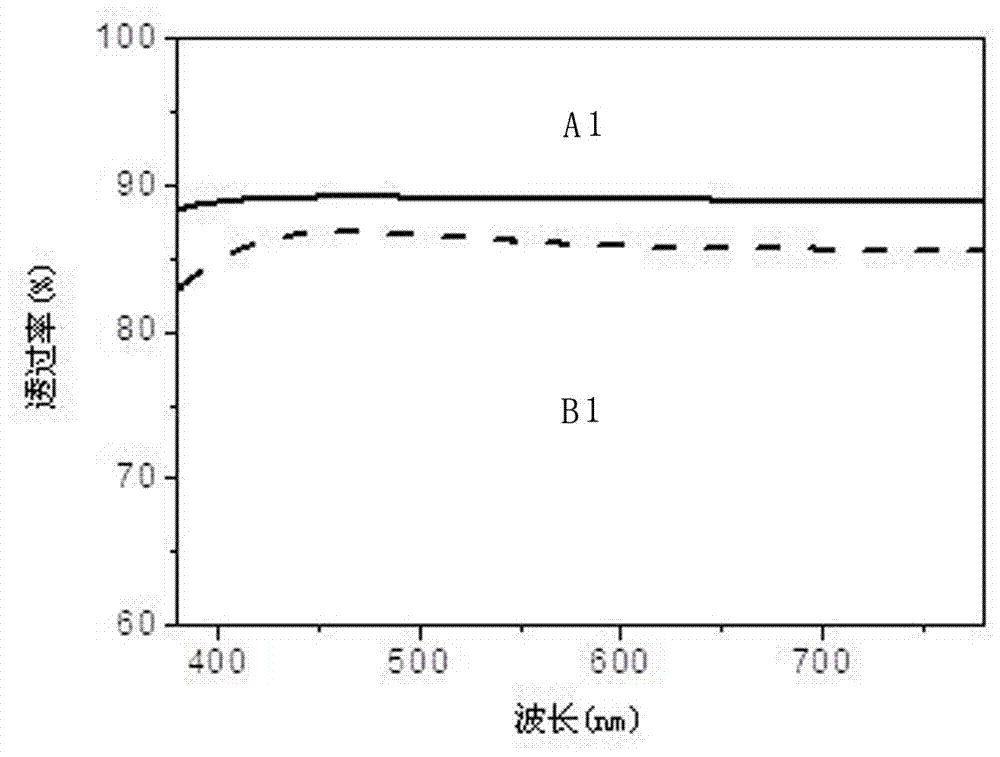

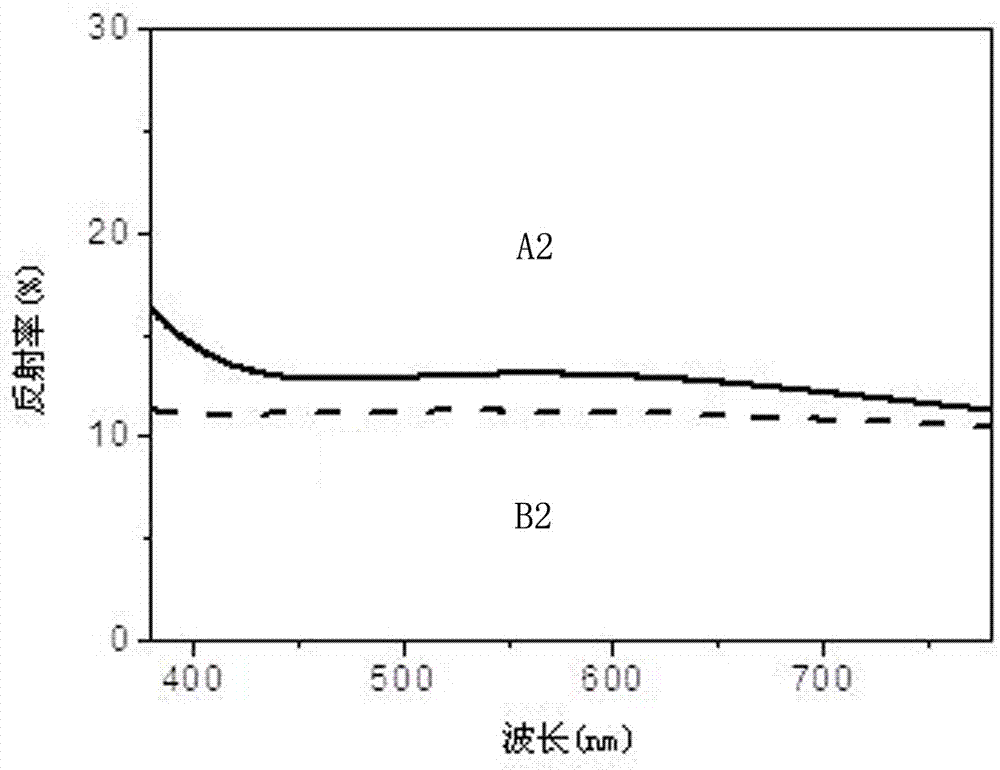

[0019] Such as figure 1 As shown, the present invention provides a kind of disappearing anti-reflection transparent conductive film, comprising substrate 1, the top surface of substrate 1 is provided with upper silicon oxynitride film layer 2 and upper SiO 2 Film layer 3, upper silicon oxynitride film layer 2 and upper SiO 2 The film layer 3 constitutes a set of upper composite film layers; the bottom surface of the substrate 1 is provided with a lower silicon oxynitride film layer 4 and a lower SiO 2 Film layer 5, lower silicon oxynitride film layer 4 and lower SiO 2 The film layer 5 constitutes a group of lower composite film layers; the outer membrane surface of the upper composite film layer is provided with an ITO layer 6; the molecular formula of the silicon oxynitride is SiN x o y , where x, y are the moles of nitrogen and oxygen respectively, x=1.213, y=0.181, x / y=6.7, SiN x o y The refractive index of the substrate 1 is 1.9; the thickness of the substrate 1 is 1....

Embodiment 2

[0028] In this embodiment, the film structure distribution of the antireflection and anti-reflection transparent conductive thin film is consistent with that in Embodiment 1, and the SiN x o y Where x=1, y= 1 / 3, x / y=3, SiN x o y The refractive index of the substrate 1 is 1.75; the thickness of the substrate 1 is 0.1mm, the thickness of the upper silicon oxynitride film layer 2 is 51nm, and the upper SiO 2 The thickness of the film layer 3 is 34nm, the thickness of the lower silicon oxynitride film layer 4 is 80nm, and the lower SiO 2 The thickness of the film layer 5 is 68nm, the surface resistance of the ITO layer 6 is 200Ω / □, and the thickness is 23nm. combine Figure 4 and Figure 5Shown, under D65 light source condition, the visible light transmission spectrum A3 of ITO layer 6 unetched regions, the visible light transmission spectrum B3 of ITO layer 6 etched regions, the visible light reflectance spectrum A4 of ITO layer 6 unetched regions, the ITO layer 6 etched reg...

Embodiment 3

[0037] In this embodiment, the ITO layer 6 in the anti-reflection and anti-reflection transparent conductive thin film is arranged on the outer film surface of the lower composite film layer, and the distribution of other film structures is consistent with that of Embodiment 1. SiN x o y Where x=4 / 3, y= 0, SiN x o y The refractive index is 2.0; the thickness of the substrate 1 is 0.6mm, the thickness of the upper silicon nitride oxide film layer 2 is 18nm, and the upper SiO 2 The thickness of the film layer 3 is 30nm, the thickness of the lower silicon oxynitride film layer 4 is 20nm, and the lower SiO 2 The thickness of the film layer 5 is 100nm, the surface resistance of the ITO layer 6 is 130Ω / □, and the thickness is 35nm. combine Figure 6 and Figure 7 Shown, under D65 light source condition, the visible light transmission spectrum A5 of ITO layer 6 unetched regions, the visible light transmission spectrum B5 of ITO layer 6 etched regions, the visible light reflectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com