Polyester release film for optical film and preparation method of polyester release film

A technology of optical film and release film, applied in the direction of coating, etc., can solve problems such as stickiness of coating film, film surface curing hindrance, etc., to achieve the effect of promoting surface curing, improving performance and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, a polyester release film for an optical film, the polyester release film comprises a release film layer and a polyester film layer, the release film layer is arranged on one side of the polyester film layer, and the release film layer consists of The raw material composition of the following parts by weight: 10 parts of glycol, 10 parts of isophthalic acid, 10 parts of oxalic acid, 5 parts of crosslinking agent, 5 parts of additive, 5 parts of polymerization inhibitor, 5 parts of catalyst, 5 parts of accelerator 5 parts, 5 parts of dye, 5 parts of lubricant, 1 part of wax.

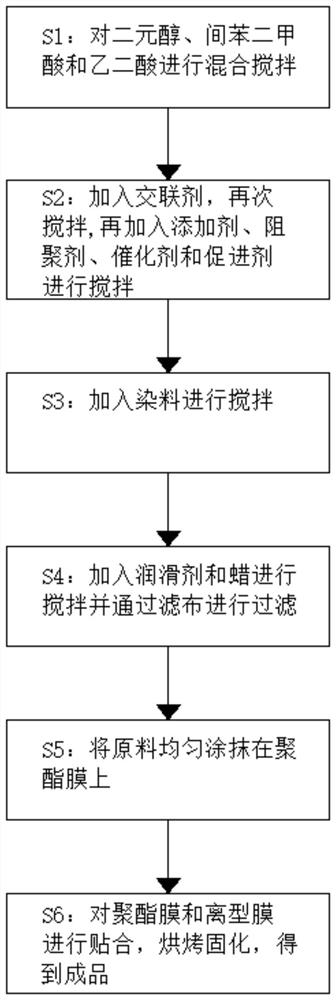

[0028] A method for preparing a polyester release film for an optical film, comprising the following steps: S1: adding glycol, isophthalic acid and oxalic acid into a container for mixing and stirring, and after the stirring is completed, leave it to stand for use; S2 : Add cross-linking agent into the mixed container, mix and stir again, and then add additives, polymerization inhibito...

Embodiment 2

[0029] Embodiment 2, a kind of polyester release film for optical film, polyester release film comprises release film layer and polyester film layer, release film layer is arranged on one side of polyester film layer, release film layer consists of The raw material composition of the following parts by weight: 15 parts of glycol, 11 parts of isophthalic acid, 10 parts of oxalic acid, 5 parts of crosslinking agent, 1 part of additive, 1 part of polymerization inhibitor, 1 part of catalyst, 1 part of accelerator 1 part, 1 part of dye, 1 part of lubricant, 1 part of wax, and the glycol is any one of phthalic anhydride, propylene glycol, diethylene glycol or dipropylene glycol.

[0030] A method for preparing a polyester release film for an optical film, comprising the following steps: S1: adding glycol, isophthalic acid and oxalic acid into a container for mixing and stirring, and after the stirring is completed, leave it to stand for use; S1 The medium stirring speed is 200-500r...

Embodiment 3

[0032] Embodiment 3, a kind of polyester release film for optical film, polyester release film comprises release film layer and polyester film layer, release film layer is arranged on one side of polyester film layer, release film layer consists of The raw material composition of the following parts by weight: 15 parts of glycol, 10 parts of isophthalic acid, 10 parts of oxalic acid, 5 parts of crosslinking agent, 5 parts of additive, 5 parts of polymerization inhibitor, 5 parts of catalyst, 5 parts of accelerator 5 parts, 5 parts of dye, 5 parts of lubricant, 2 parts of wax, the glycol is any one of phthalic anhydride, propylene glycol, diethylene glycol or dipropylene glycol, and the crosslinking agent is styrene Any one of , methyl methacrylate or diallyl phthalate.

[0033] A method for preparing a polyester release film for an optical film, comprising the following steps: S1: adding glycol, isophthalic acid and oxalic acid into a container for mixing and stirring, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com