Pod-shaped elastic supporting rod device

A technology of elastic support rods and pods, which is applied in the fields of aviation and aerospace, can solve the problems of high damage rate, low yield, and low bearing capacity of pod rods, and achieve the effect of improving bearing capacity and yield, and reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

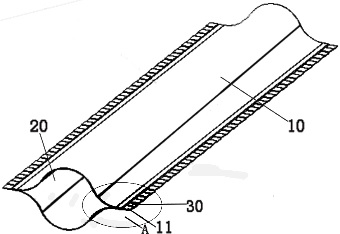

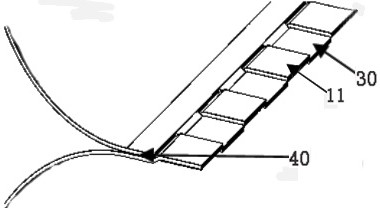

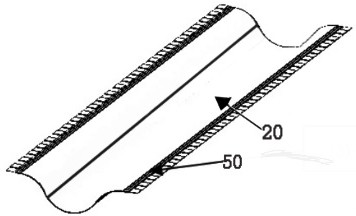

[0049] refer to Figure 1-Figure 4 , the present invention provides a pod-shaped elastic support bar device, comprising a pod upper lobe 10 and a pod lower lobe 20, both side edges of the pod upper lobe 10 and the pod lower lobe 20 include an adhesive surface 50 and a straight plane 60; Algorithms 11 arranged at intervals are successively arranged on the 60, and the alveoli 11 of the pod upper lobe 10 and the lower lobe 20 of the pod are intersected with each other, and a toughened fiber sheet 30 is arranged between adjacent alveoli 11, and the toughened Silica gel is coated on the type fiber sheet 30, the bonding surface 50, and the intersection 40 of the pod upper lobe 10 and the pod lower lobe 20, and the pod upper lobe 10 and the pod lower lobe 20 are bonded together by a flattening process through silica gel.

[0050] The alveoli 11 of the upper lobe 10 of the pod and the lower lobe 20 of the pod are intersected with each other. When the upper lobe 10 of the pod is bonded...

Embodiment 2

[0053] The present invention also provides a pod-shaped elastic support rod device, which differs from Embodiment 1 in that the device also includes specific holes (not shown in the figure) for preset elongated holes. The specific holes of the holes are located symmetrically on the straight sides of the upper 10 and lower 20 petals of the pod; strips of Velcro (not shown) are attached to the outer surface of the device.

[0054] It should be noted that the preset specific holes are for the subsequent use with other components in preparation for mutual use; the outer surface is attached with a strip of Velcro velcro, which can stick the overlapped club faces tightly after the device is wound up , capable of constraining the device from popping open.

[0055] Other content is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com