Nano hardness measurement method for multiphase molybdenum alloy

A technology of nano-hardness and measurement method, which is applied in the direction of measurement device, testing material hardness, preparation of test samples, etc., can solve the problems of high hardness and difficult to polish, and achieve the effect of accurate and efficient measurement method, suitable promotion and reduction of measurement cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

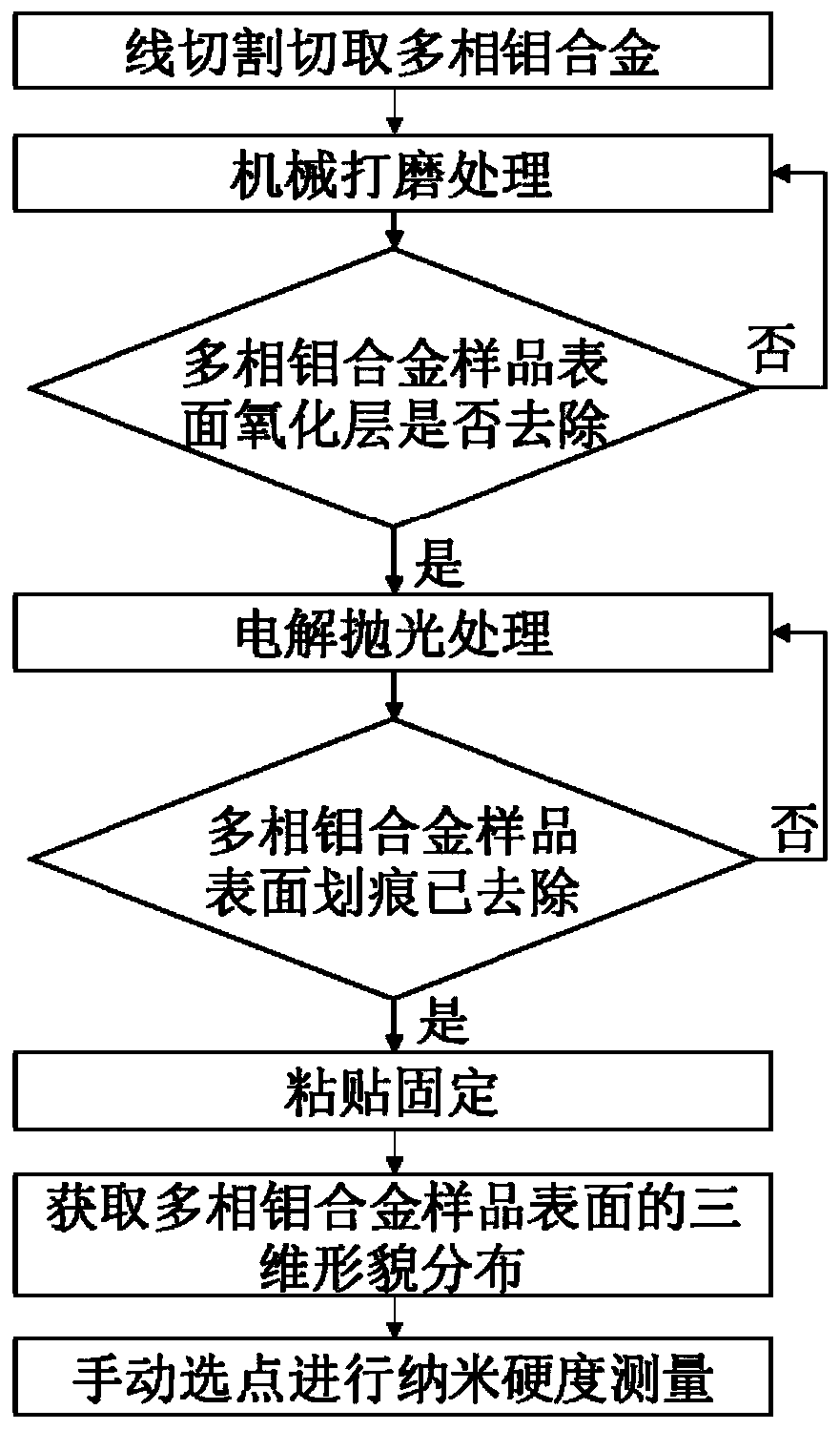

[0032] This embodiment includes the following steps:

[0033] Step 1, using wire cutting to cut Mo-Si-B alloy samples with a size of 5 mm × 5 mm × 3 mm (length × width × height) on the Mo-Si-B alloy block prepared by powder metallurgy sintering method;

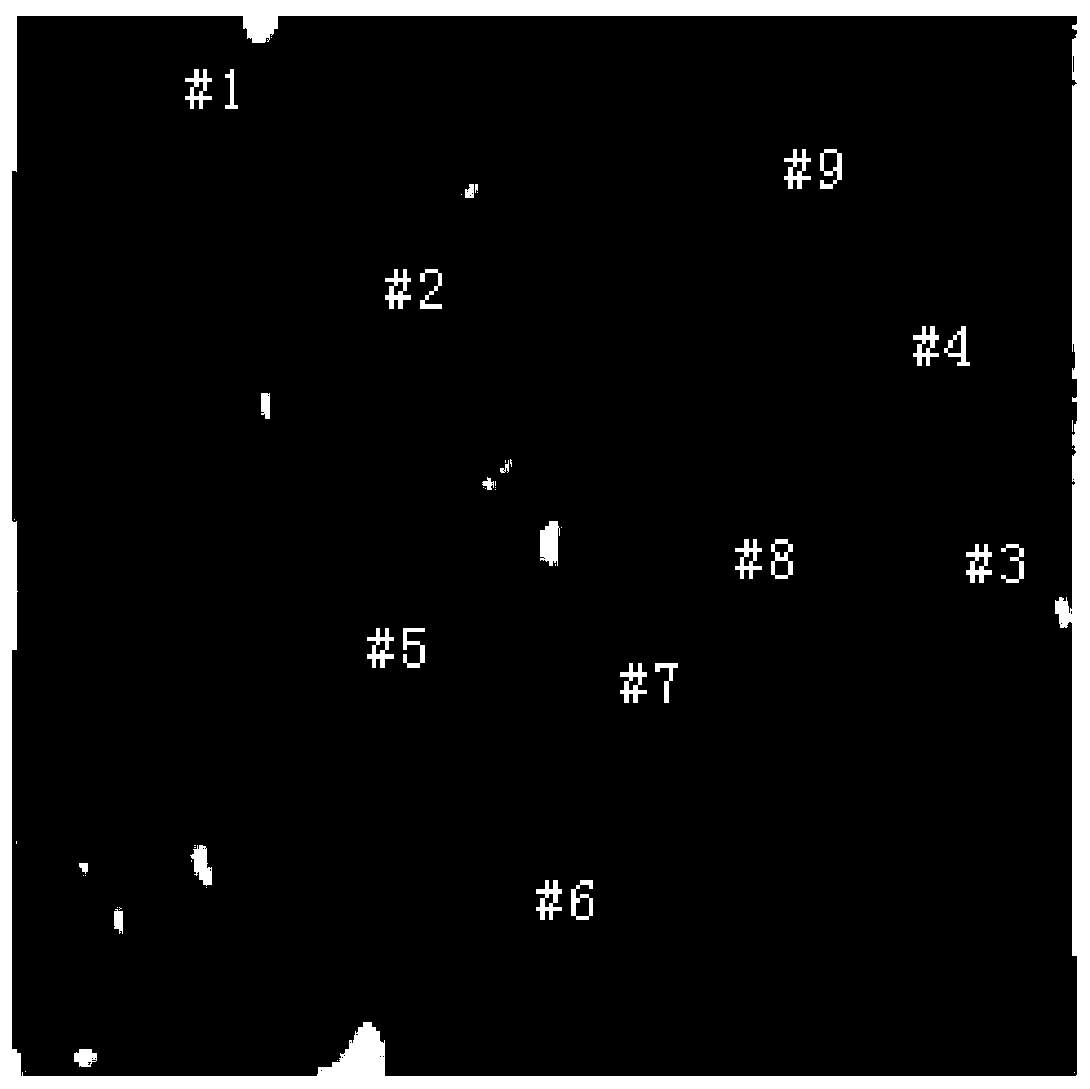

[0034] Step 2. Use 200 mesh, 500 mesh, 800 mesh, 1200 mesh and 2000 mesh silicon carbide sandpaper in sequence to mechanically polish the Mo-Si-B alloy sample cut in step 1 to a depth of 0.3mm, and then perform electrolytic polishing , followed by ultrasonic cleaning and drying with a hair dryer; the electrolytic polishing process is carried out at 20°C to 35°C, the electrolytic cell used is a 250mL glass beaker, and the mechanically polished Mo-Si -B alloy sample is the anode as a whole, and the stainless steel sheet is used as the cathode. The DC voltage is controlled and the voltage is 20V. The electrolytic polishing solution used is a sulfuric acid ethanol solution with a sulfuric acid volume fraction of 10%. During the p...

Embodiment 2

[0042] Step 1, using wire cutting to cut out a Mo-Si-B alloy sample with a size of 5mm×5mm×3mm (length×width×height) on the Mo-Si-B alloy substrate prepared by the laser remelting method;

[0043] Step 2. Use 200 mesh, 500 mesh, 800 mesh, 1200 mesh and 2000 mesh silicon carbide sandpaper in sequence to mechanically polish the Mo-Si-B alloy sample cut in step 1 to a depth of 0.3mm, and then perform electrolytic polishing , followed by ultrasonic cleaning and drying with a hair dryer; the electrolytic polishing process is carried out at 20°C to 35°C, the electrolytic cell used is a 250mL glass beaker, and the mechanically polished Mo-Si The whole of the -B alloy sample is the anode, and the stainless steel sheet is used as the cathode. The DC voltage is controlled and the voltage is 30V. The electrolytic polishing solution used is a sulfuric acid ethanol solution with a sulfuric acid volume fraction of 5%. During the process, slightly shake the anode stainless steel tweezers to ...

Embodiment 3

[0051] The difference between this embodiment and Example 2 is that the voltage used for electropolishing in step two is 25V, the electropolishing solution used is a sulfuric acid ethanol solution with a sulfuric acid volume fraction of 8%, and the electropolishing time is 20s; step three 502 glue is used for pasting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com