Hob shredding type multifunctional green feed harvester

A green forage harvester and multi-functional technology, applied in the field of hob-cutting multi-functional green forage harvester, can solve the problems of short life and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the embodiments given in the accompanying drawings.

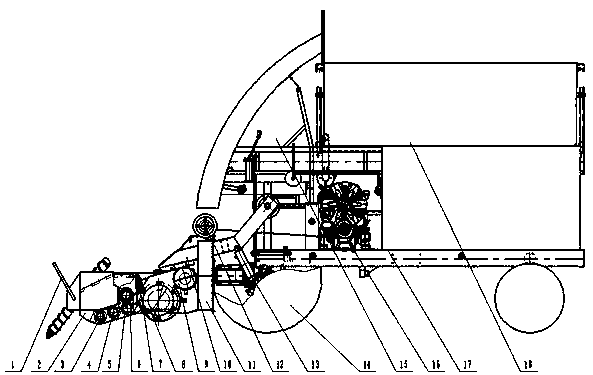

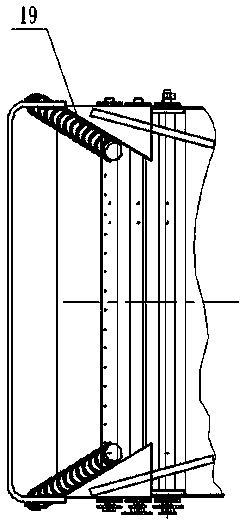

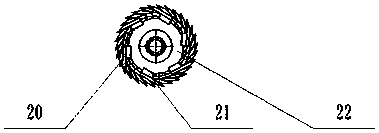

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , a hob shredding type multi-functional green forage harvester, comprising a crop press 1, a header side plate 2, a rhizome cutting hob 3, a primary grass guide roller 4, a secondary grass guide roller 5, a cutting feeder Roller 6, fixed knife mechanism 7, hob cutting device 8, conveying auger 9, frame 10, conveying fan part 11, transmission system 12, header lifting part 13, walking part 14, cab 15, engine 16, The main frame 17, the silo 18 and the longitudinal grain collecting part 19, etc., are characterized in that: the rhizome cutting hob 3 is cut from the bottom to the top in the direction of rotation, forming a neatly inclined incision to meet the secondary growth of paper mulberry. requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com