Anti-deformation cutting device of metal hose

A technology for metal hoses and cutting devices, which is applied in the direction of pipe shearing devices, shearing devices, and attachments to shearing machines, etc., which can solve the problems that metal hoses are prone to deformation and affect the use efficiency, so as to reduce deformation and prevent wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

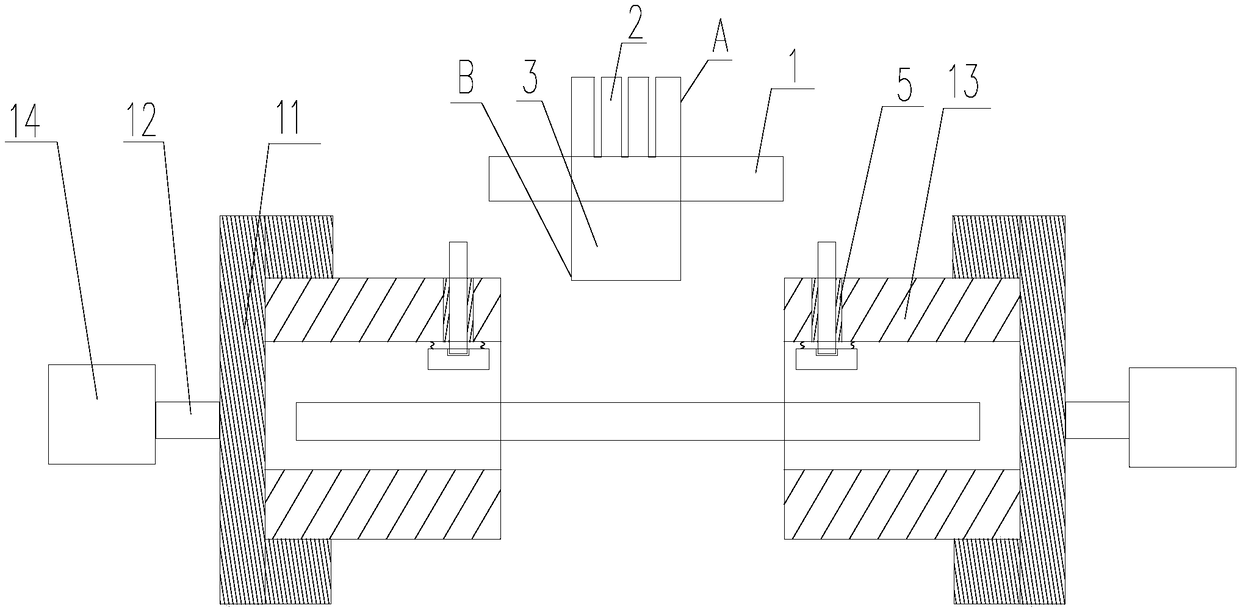

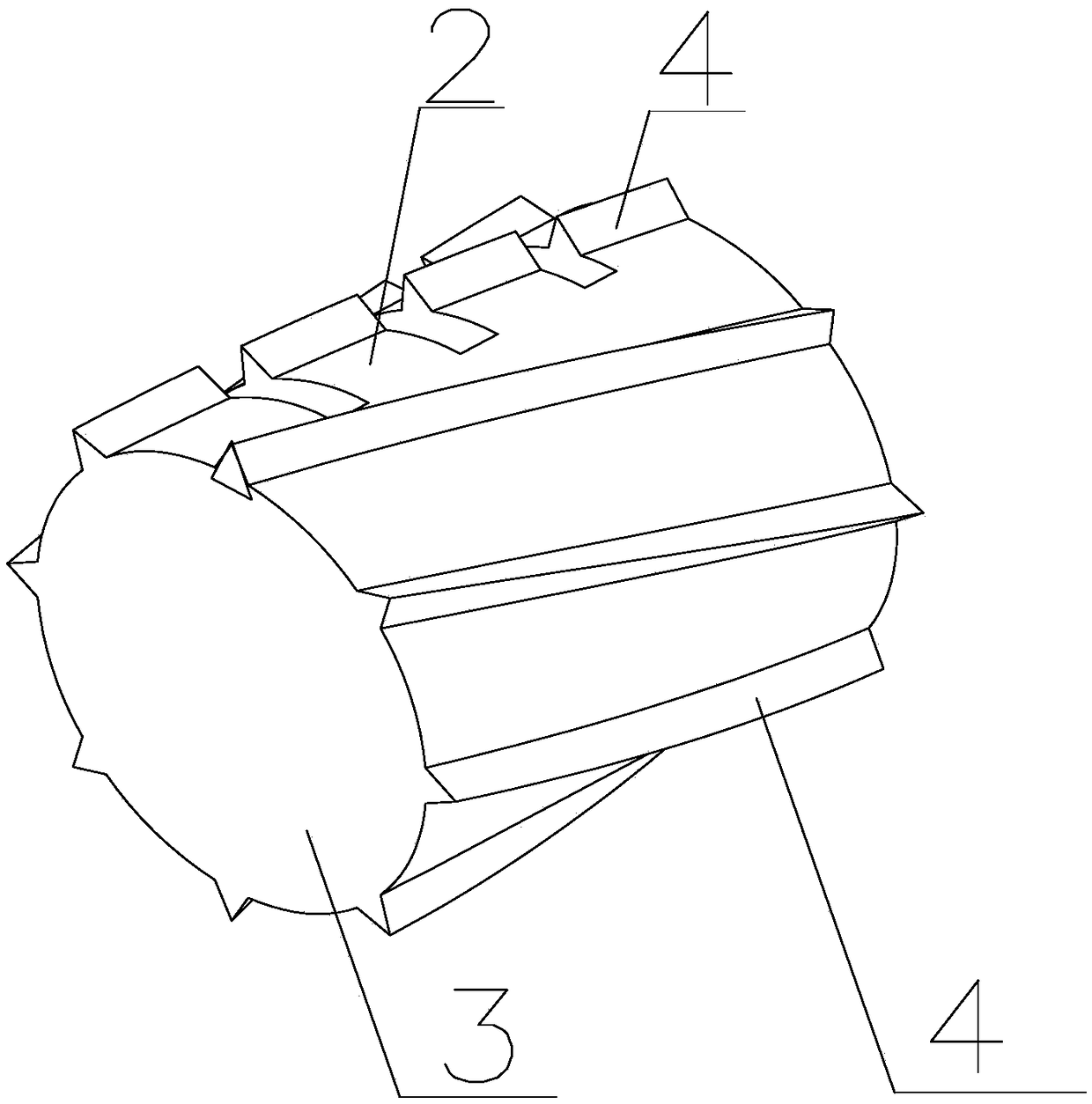

[0033] Such as Figure 1~5 As shown, a metal hose anti-deformation cutting device of the present invention includes a cutting knife body, the cutting knife body is cylindrical, and the cutting knife body is divided into two parts A and B along the plane where the axis is located, and the A part is composed of four parts. The first cutting knife 2 is composed of four first cutting knives 2 arranged in sequence along the line where the axis of the cutting knife body is located, part B is a second cutting knife 3, the cross-sections of the first cutting knife 2 and the second cutting knife 3 are equal It is half of the cross-section of the cutter body, the axis of the first cutter 2 and the second cutter 3 coincide with the axis of the cutter body; the axes of the cutter body and the metal hose are parallel to each other, and the rotational speed of the cutter body It is 0.5N times the rotation speed of the metal hose, where N is a positive integer, and the cutter body only rotat...

Embodiment 2

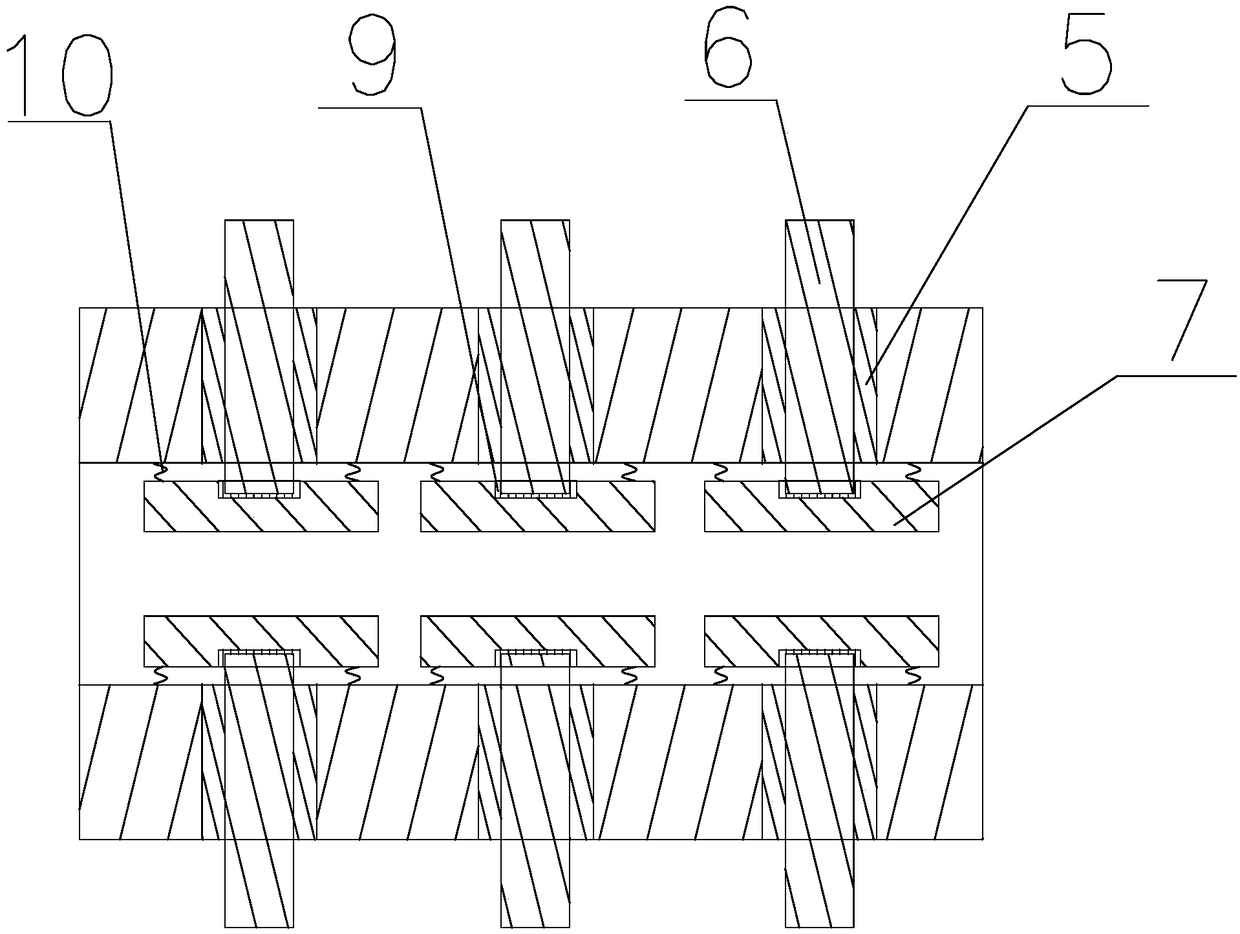

[0035] An anti-deformation cutting device for metal hoses. On the basis of Embodiment 1, the straight lines where the four through holes 5 are located are on the cross-section of the placement box 13, and the straight lines where the four through holes 5 are located are two mutually perpendicular straight lines . The placement box 13 is provided with three groups of four through holes 5 , including a hollow cylinder formed by three groups of four connecting plates 7 . The length of the connecting rod 6 is greater than half of the thickness of the placement box 13 . Both the first cutting knife 2 and the second cutting knife 3 are connected with a sharp cutting piece 4 at one end, the cutting piece 4 is spirally distributed on the first cutting knife 2 and the second cutting knife 3, and the cutting piece 4 is connected with the metal soft When the pipe cutting surfaces are in contact, the angle between the cutting piece 4 and the horizontal plane is 30 degrees.

Embodiment 3

[0037] An anti-deformation cutting device for metal hoses, the two ends of metal hoses with a thickness of 50mm are placed in a placement box, the hollow part of the placement box 13 is a cylinder with a diameter of 200mm, and the length of the connecting rod 6 is 110mm. There are three groups of four through holes on the box, as well as the connecting rods and connecting plates on it, so three hollow cylinders are formed in total, and the metal hose is fixed in the three hollow cylinders on the same axis. The connecting plate 7 on the upper part is in contact with the side of the metal hose and clamped so that the metal hose and the storage box 13 rotate together. The groove 9 on the connecting plate 7 is circular, and the lower end of the connecting rod 6 is a corresponding circular shape. shape, so the lower end of the connecting rod 6 snaps into the groove 9, and can rotate in the groove 9 without falling out. When the connecting rod 6 rotates, the spring on the connecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com