Sputtering target packaging box

A technology for sputtering targets and packaging boxes, applied in packaging, biological packaging, transportation and packaging, etc., can solve problems such as damage to large-scale sputtering targets, waste of storage space, damage to packaging boxes, etc., to ensure quality and safety. , easy to ship and use, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

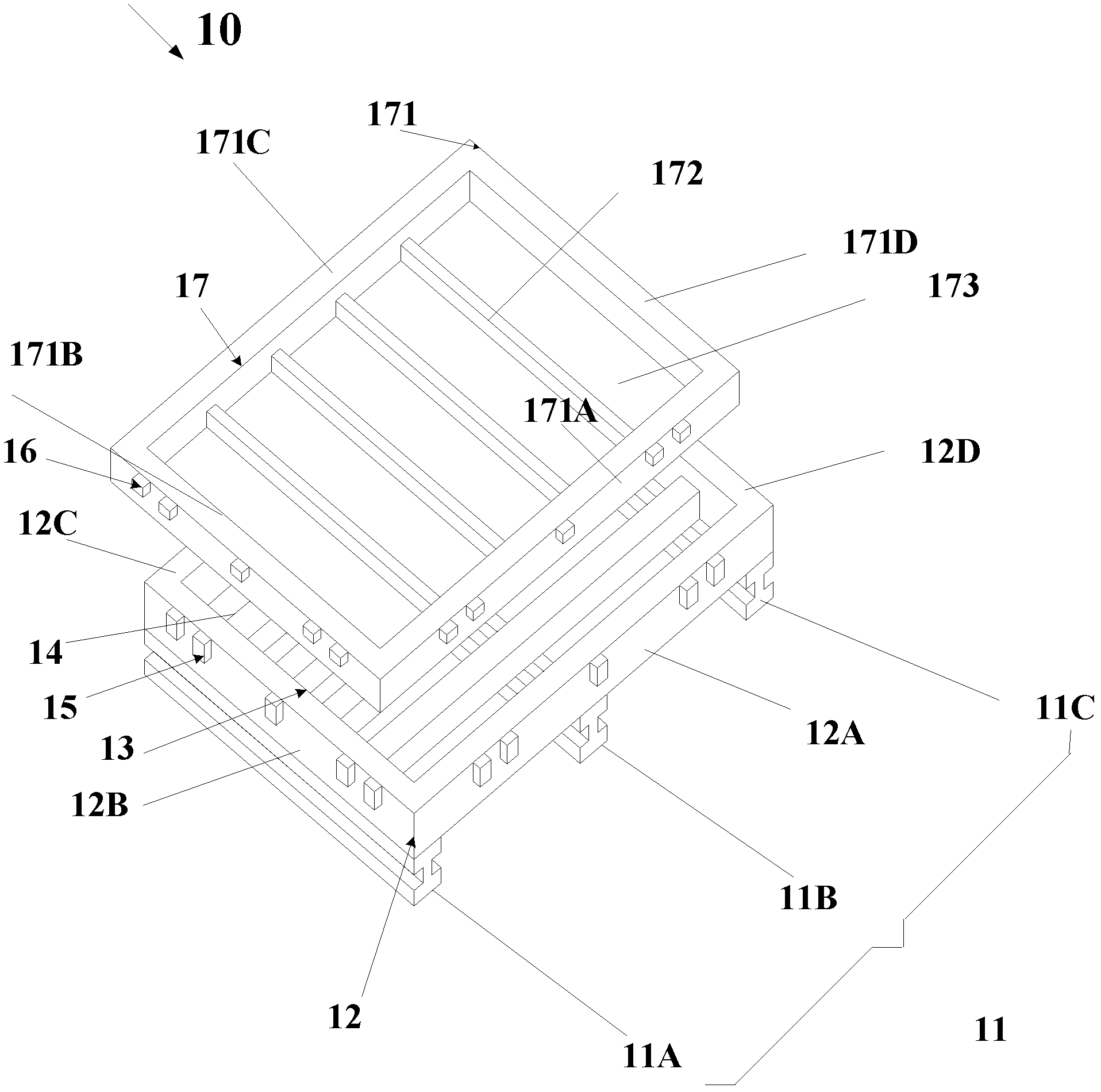

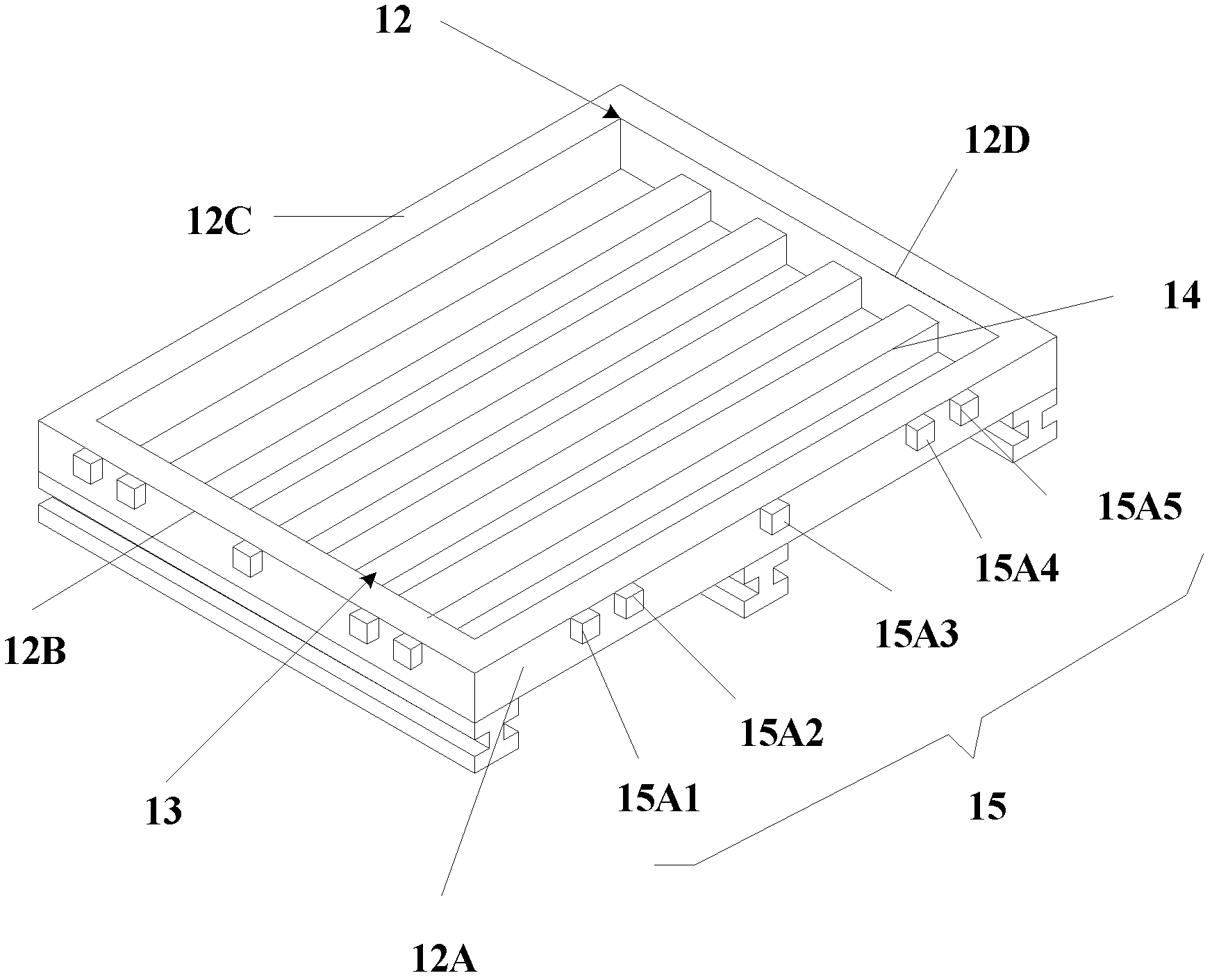

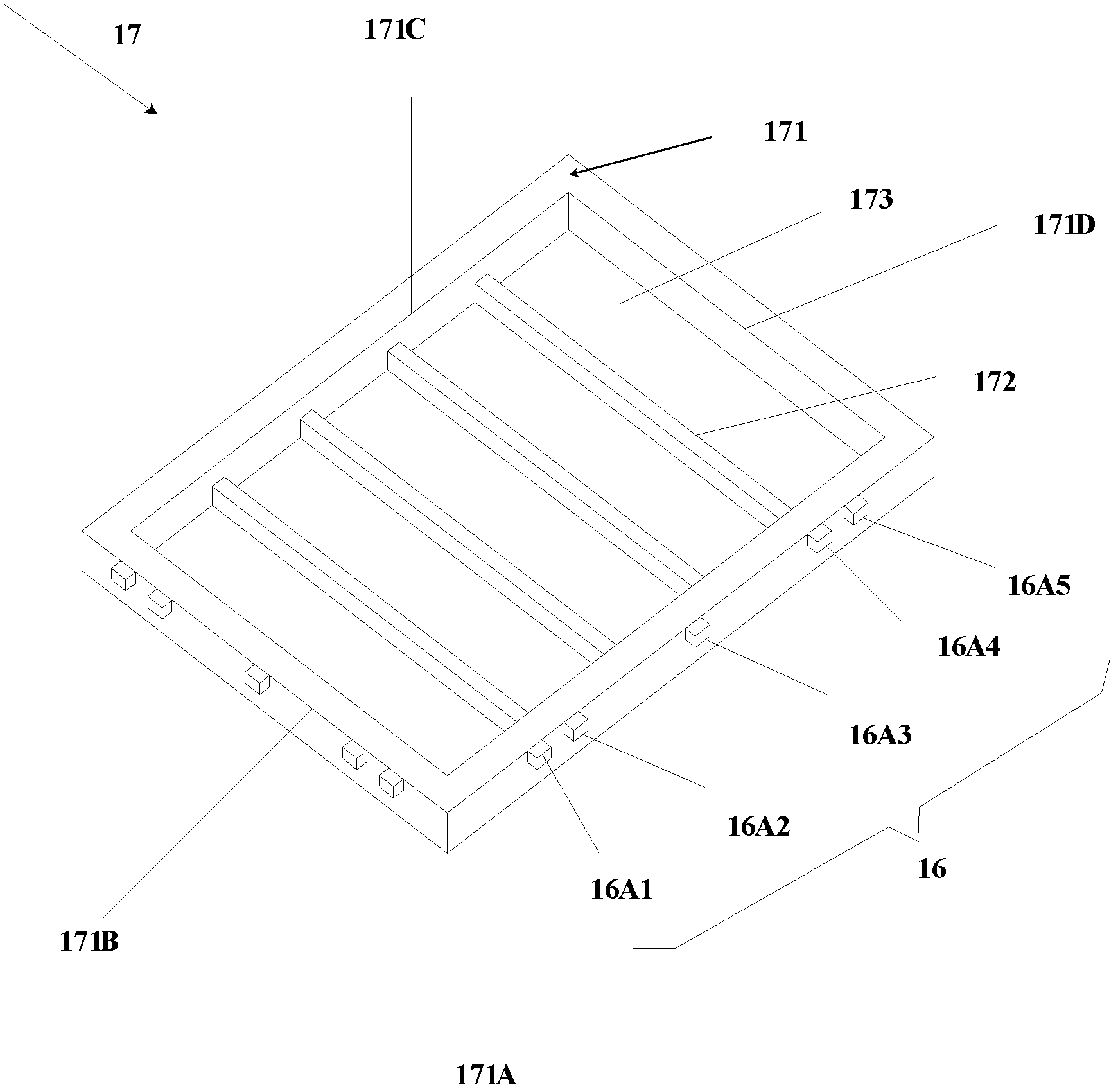

[0037] The present invention provides a sputtering target packaging box. A protective body is provided in an integrally formed enclosure, and both sides of the protective body are supported on the side plates to increase the strength of the sputtering target packaging box. ;The lock hole on the sputtering target packaging box and the interlocking design of the lock can make the packaging box repeatedly disassembled and installed, which is convenient for shipment and flexible use; the base has at least two isolated I-beams , the load-bearing capacity of the sputtering target packaging box is improved, and the frame-type cover of the above-mentioned packaging box is located on the enclosure, which also improves the load-bearing capacity of the sputtering target packaging box and reduces the damage rate of the target .

[0038] A preferred embodiment of the present invention is a large-scale sputtering target packaging box that uses I-shaped steel as the base and is built with al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com