Rapid fixing device and method for constructional engineering formwork

A technology of construction engineering and fixing devices, which is applied in the direction of construction, building structure, and on-site preparation of building components. It can solve the problems of long time-consuming vertical formwork, time-consuming and labor-intensive manual movement, and low construction efficiency. Compact design, increased sealing and engaging performance, and solved the effect of inconvenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

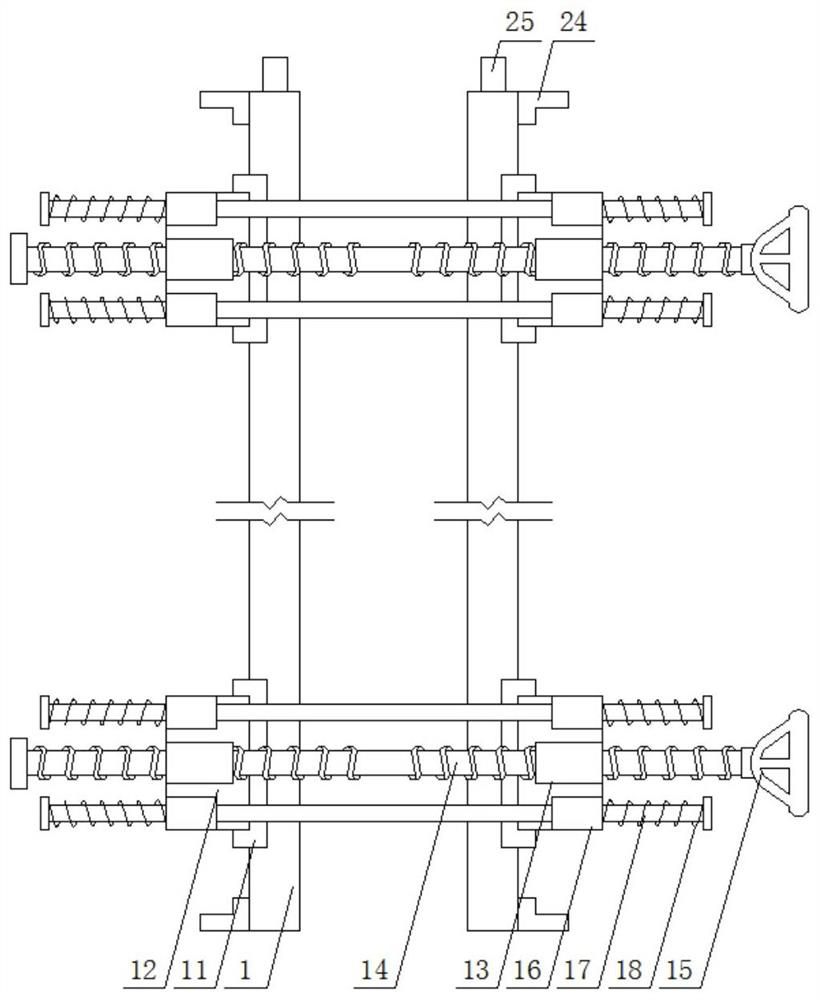

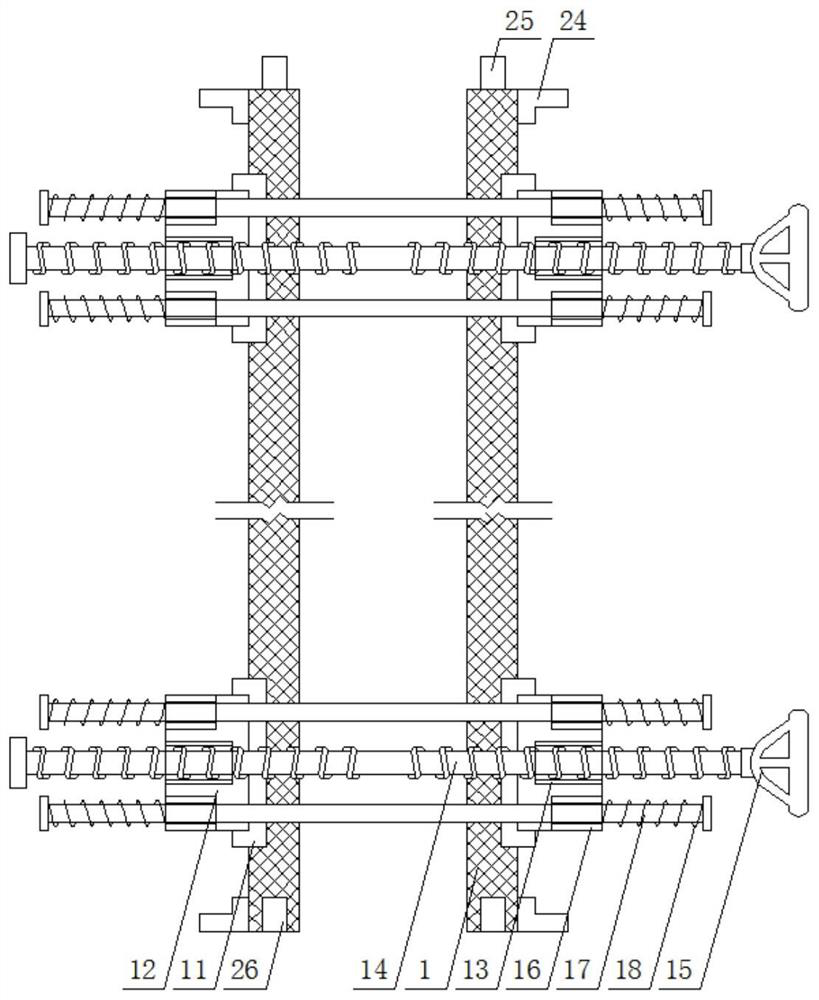

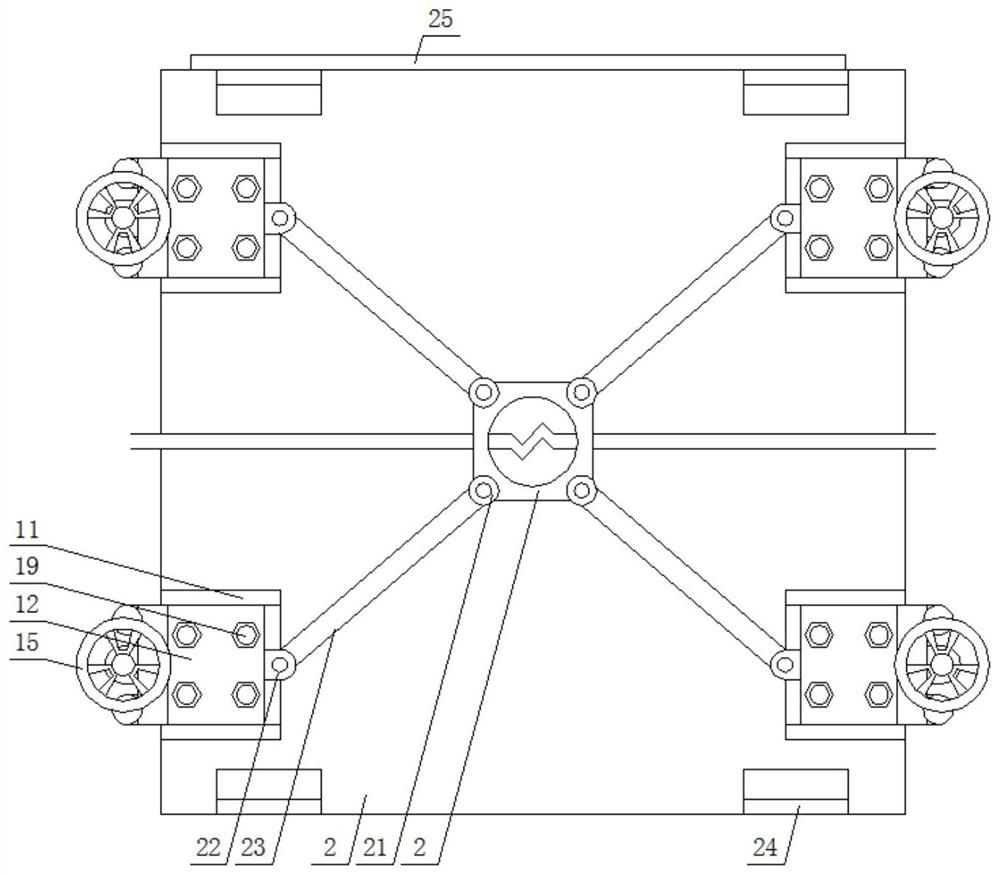

[0032] Embodiment 1: This embodiment provides a fast fixing device for construction engineering formwork, see figure 1 , figure 2 , image 3 Specifically, it includes a pair of templates 1, an adjustment mechanism, and hinges. A pair of templates 1 are placed vertically and parallel on the ground, and the four corners of the outer surface of each template 1 are provided with inlaid and welded U-shaped plates 11 , the outer surface of each U-shaped plate 11 is provided with an L-shaped plate 12, see Figure 5 , Image 6 , the two adjacent L-shaped plates 12 are connected by an adjustment mechanism; the middle part of the outer side of each template 1 is provided with a square plate 2, and each square plate 2 is connected to the corresponding L-shaped plate 12 through a hinge connect.

[0033] Specifically, the adjustment mechanism includes a threaded cylinder 13 and a two-way lead screw 14. The middle part of the side of each L-shaped plate 12 is provided with a horizontal...

Embodiment 2

[0036] Embodiment 2: In Embodiment 1, there is still the problem that the L-shaped plate is not firmly fixed. Therefore, on the basis of Embodiment 1, this embodiment also includes a hinge:

[0037] Specifically, the hinge includes a hinge rod 23, the middle of the square plate 2 is provided with a circular hole, the four corners of the square plate 2 are provided with a first hinge seat 21, and the inner side of each L-shaped plate 12 is provided with a circular hole. There is a second hinged seat 22, and the two ends of the hinged rod 23 are respectively hinged with the corresponding first hinged seat 21 and the second hinged seat 22; The hinged seat 21 and the second hinged seat 22 are movable latches, so that an effective fixed connection is added between the L-shaped plates 1 at the four corners of the template 1 .

Embodiment 3

[0038] Embodiment 3: In embodiment 1, there is also the problem of inconvenient splicing of multiple sets of templates. Therefore, on the basis of embodiment 1, see Figure 4 In this embodiment, a rectangular groove 26 is provided on the bottom surface of the formwork 1, and a rectangular clamping plate 25 is provided on the top surface of the formwork 1, and the rectangular clamping plate 25 is engaged in the rectangular groove 26 of another set of formwork 1, thereby increasing the formwork 1 and The sealing engagement performance when another set of formwork 1 is in contact.

[0039] In the present invention, a pair of L-shaped foot plates 24 are provided on the top and bottom sides of the outer surface of the formwork 1, and each L-shaped foot plate 24 is connected with the L-shaped foot plate 24 of another set of formwork 1 through connecting bolts. The cooperating use of the foot plate 24 facilitates the splicing and assembly of multiple sets of templates 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com