Screen device

A screen and casing technology, applied in the field of screen devices, can solve problems such as poor applicability, time wasting, and increased production costs, and achieve the effect of improving the applicability of splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

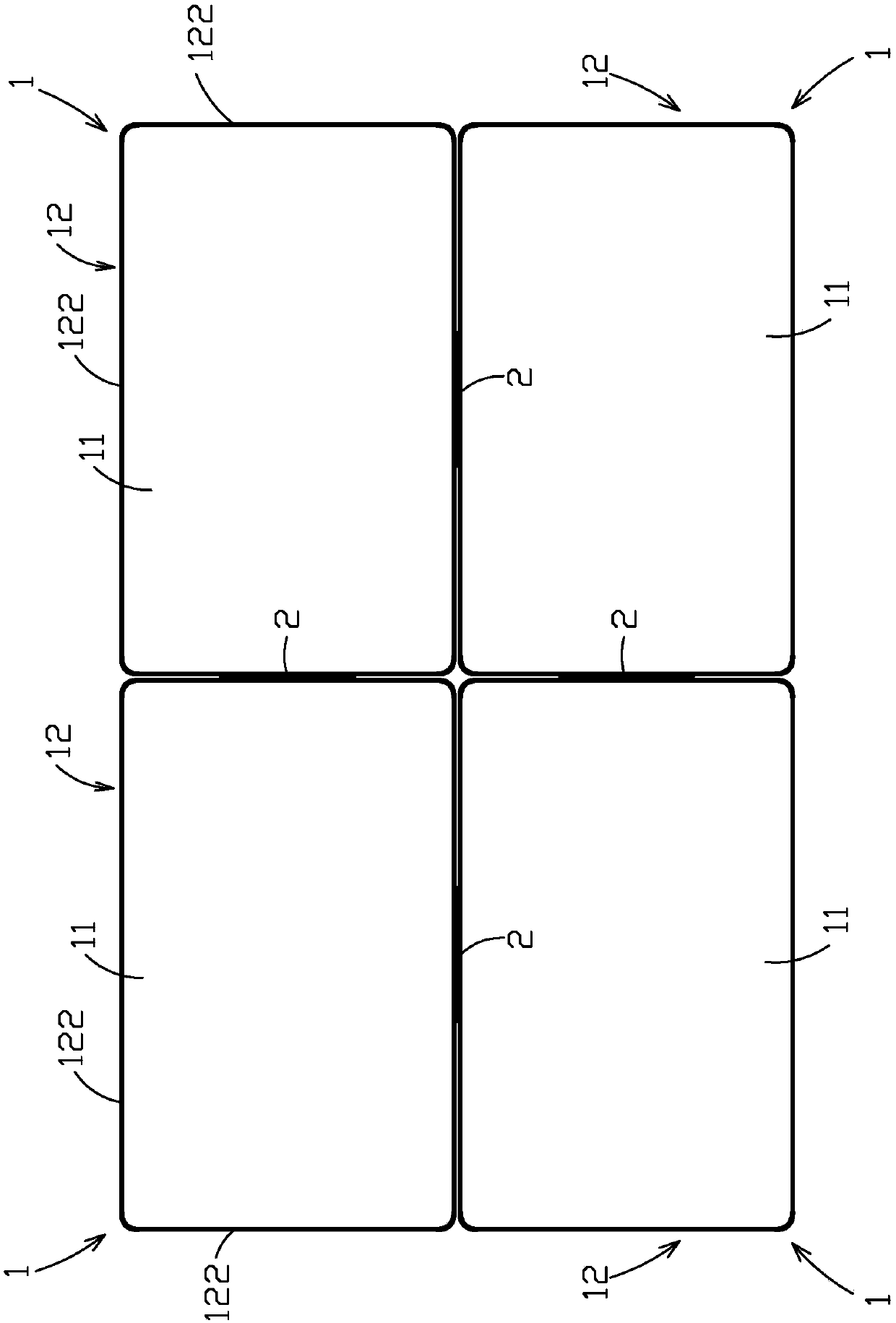

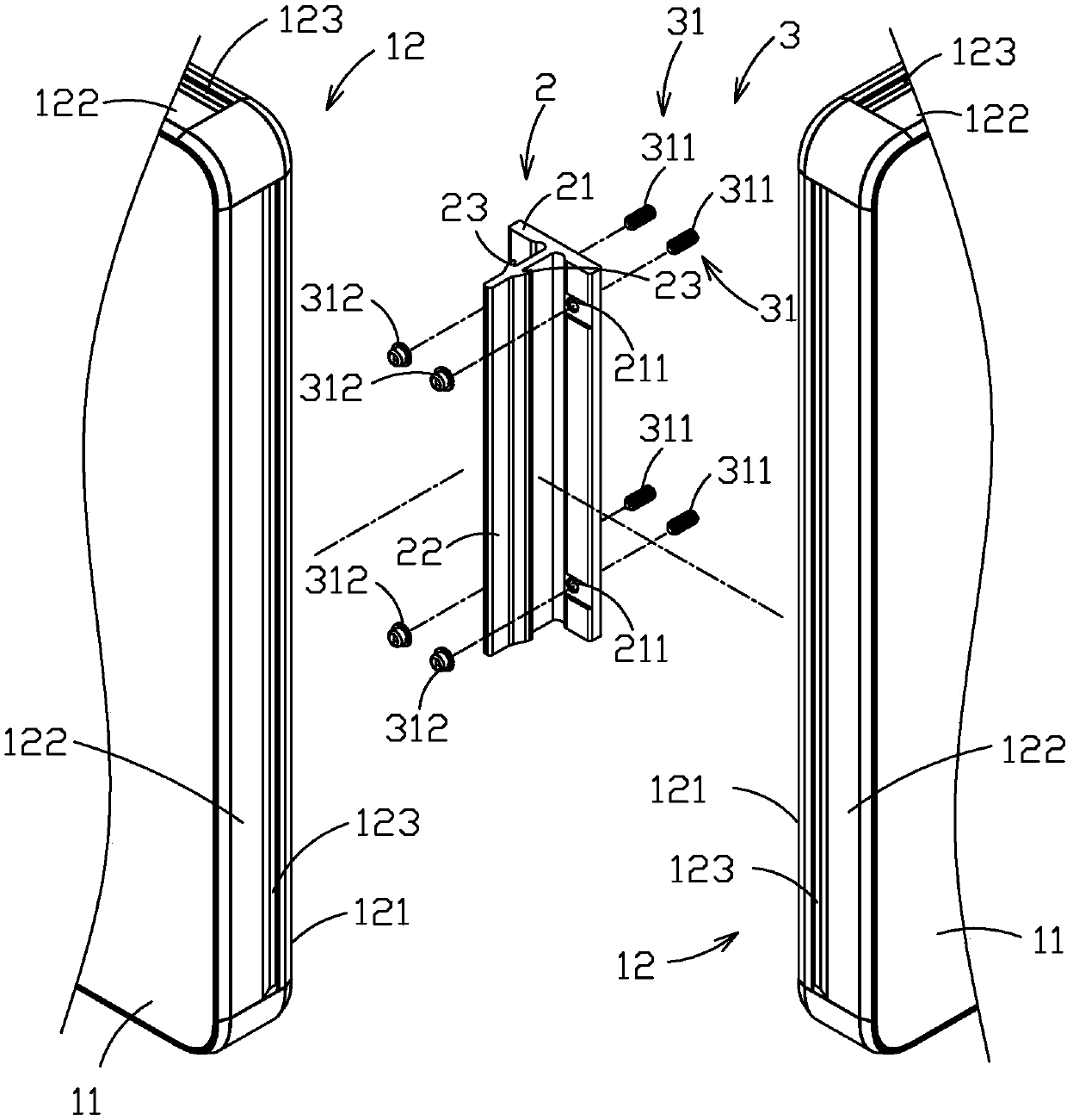

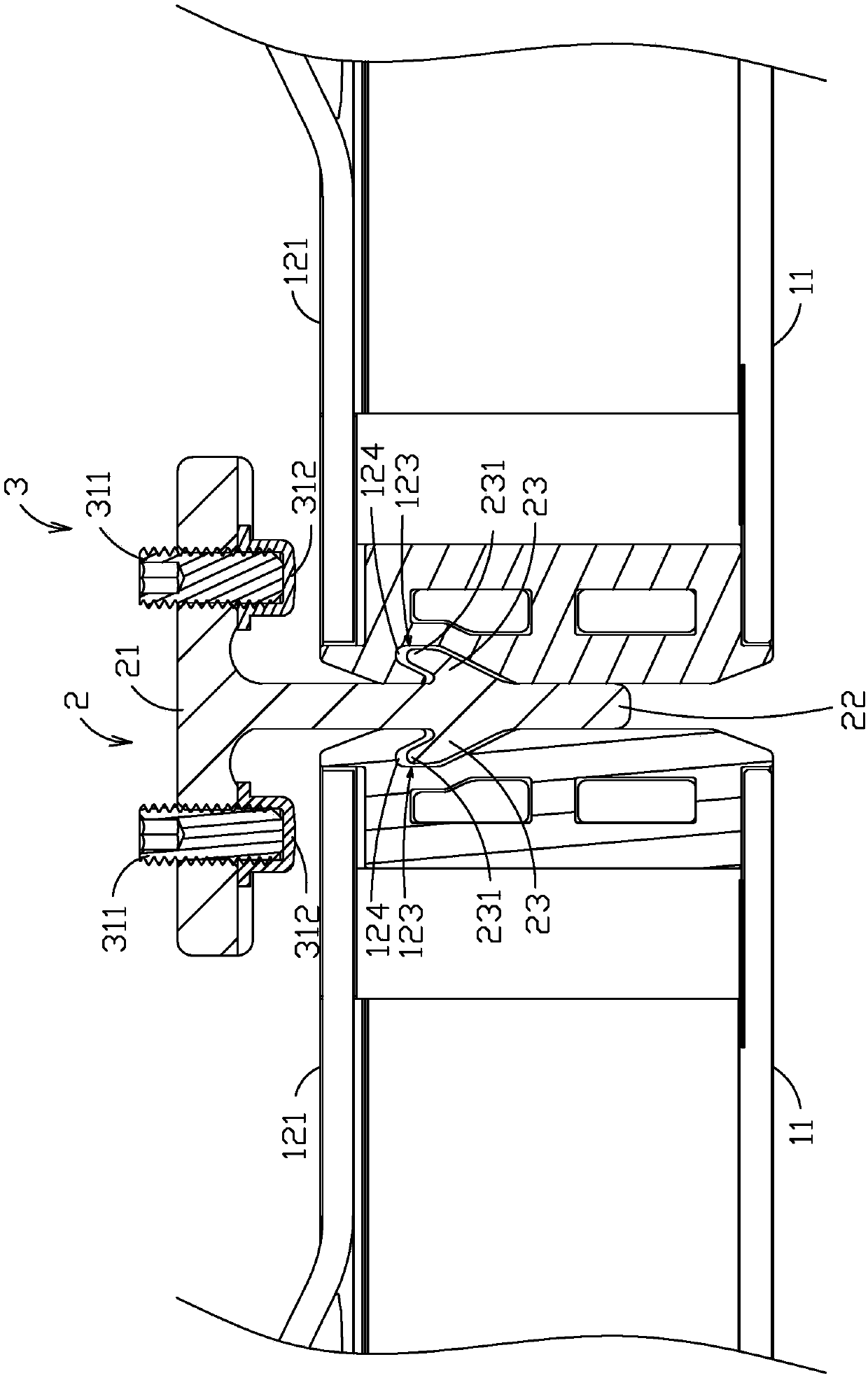

[0015] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides an embodiment of a screen device, which includes a plurality of display units 1 , a plurality of fixing brackets 2 , and a fixing unit 3 .

[0016] Each display unit 1 includes a screen 11 and a casing 12 surrounding the screen 11 . Each housing 12 has a body 121 (not shown), a plurality of frame 122 extending from the body 121 to the direction of the corresponding screen 11 and surrounding the screen 11, and a plurality of positioning slides recessed in the frame 122 Slot 123.

[0017] Each fixing bracket 2 can be combined with the shells 12 of two adjacent display units 1, and includes a fixed wall 21, a direction extending from the fixed wall 21 to the direction away from the fixed wall 21 and located in two adjacent shells 12 There is a partition wall 22 between them, and two engaging walls 23 located on two opposite sides of the partition wall 22 and extending from the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com