Interchange structure for covering existing road on newly-built expressway

A technology for expressways and interchanges, applied in the directions of roads, roads, buildings, etc., to achieve the effect of strengthening the pouring effect, the construction method is simple, and the connection strength is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

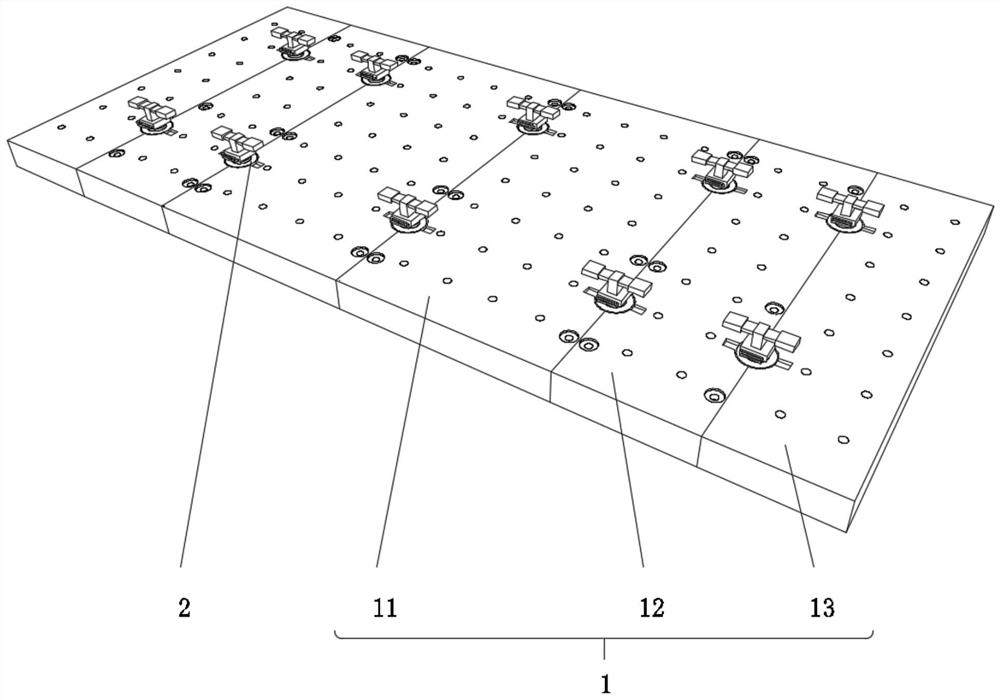

[0029] according to figure 1 As shown, the covering surface 1 is composed of a first covering surface 11, a second covering surface 12 and a third covering surface 13. When repairing the bridge deck of an interchange overpass, the first covering surface 11, the second covering surface 12 or the third covering surface 11, the second covering surface 12 or the third covering surface can be selected through the combination of repair areas. The covering surface 13 covers the bridge deck. Since the covering surface 1 is the first covering surface 11 , the second covering surface 12 and the third covering surface 13 , the transportation, repairing and splicing operations of the covering surface 1 are convenient.

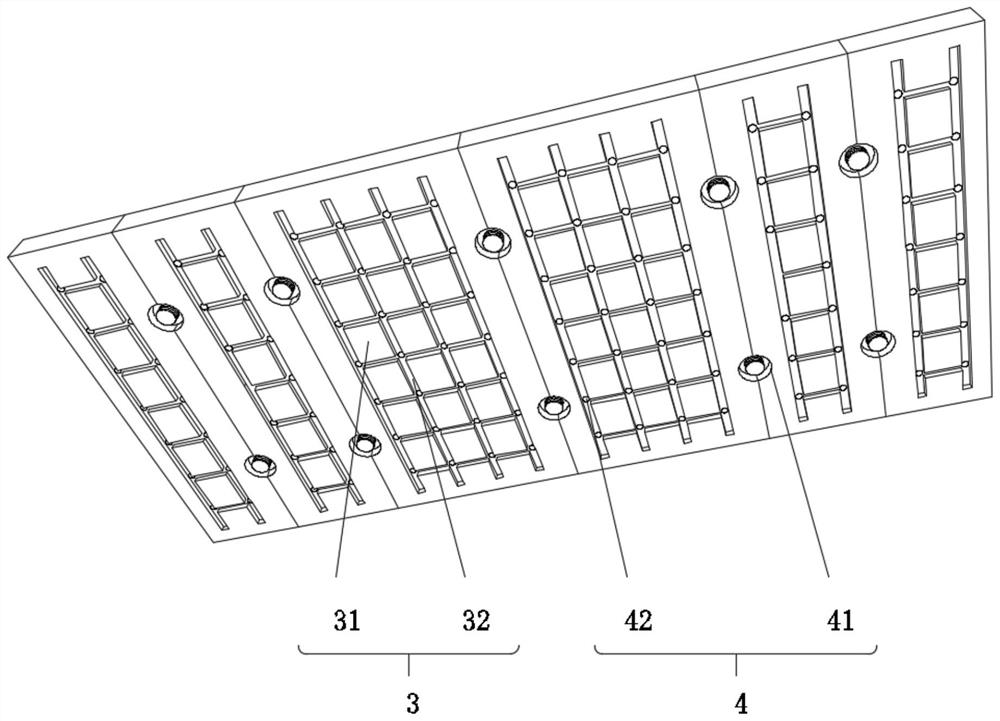

[0030] Further, the noise reduction and water absorption device 3 includes a noise reduction water absorption plate 31 and a filling groove 32, and the noise reduction water absorption plate 31 and the filling groove 32 are provided in several groups and are arranged altern...

Embodiment 2

[0033] After the cladding 1 covers the bridge deck of the interchange overpass, the noise reduction water absorbing plate 31 is brought into contact with one side of the bridge deck, so that the noise reduction absorbing plate 31 performs the noise reduction operation of the cladding 1 and the bridge deck.

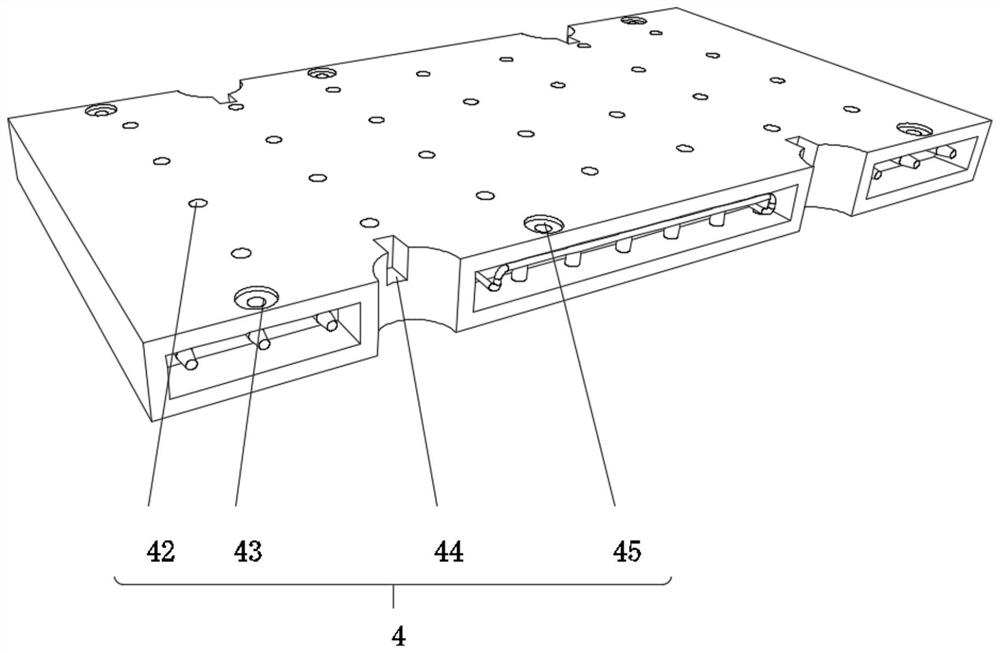

[0034] Further, the inside of the cladding 1 is provided with a pouring chamber 6, the pouring device 5 includes a first pouring steel bar 51, a steel bar 52 and a second pouring steel bar 53, and the pouring chamber 6 includes a first pouring The first pouring groove 61 of the pouring steel bar 51 is included. and the second pouring groove 62 for accommodating the second pouring steel bar 53 , the first pouring steel bar 51 is flush with the first pouring groove 61 and the second pouring steel bar 53 is flush with the second pouring groove 62 .

[0035] Further, the reinforcing bars 52 are arranged inside the first pouring groove 61, and the reinforcing bars 52 slightly pr...

Embodiment 3

[0039] After the cladding 1 is merged, concrete is added to the inside of the pouring chamber 6 through the second filling hole 43. During the merging of the cladding 1, due to the first pouring steel bar 51 and the first pouring groove 61, the second pouring steel bar 53 and the second pouring The groove 62 is flush, so after the cladding 1 is merged, the first pouring steel bar 51 is connected with the first pouring steel bar 51, and the second pouring steel bar 53 is connected with the second pouring steel bar 53, but the steel bar 52 slightly protrudes from the first pouring groove 61 and protrudes. The distance is 1cm, so the two steel bars 52 will be squeezed and deformed after contacting in the process of merging the cladding 1. After the concrete enters the pouring chamber 6, the extruded cladding 1 can be used to strengthen the pouring effect of the concrete, thereby improving the cladding 1. connection strength.

[0040] Further, the lifting device 2 includes a screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com