Orthogonal crossing steel bar positioning piece

A technology of positioning pieces and steel bars, which is applied to structural elements, building components, building reinforcements, etc., can solve problems such as difficult positioning, achieve high work efficiency, fast splicing speed, and improve positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

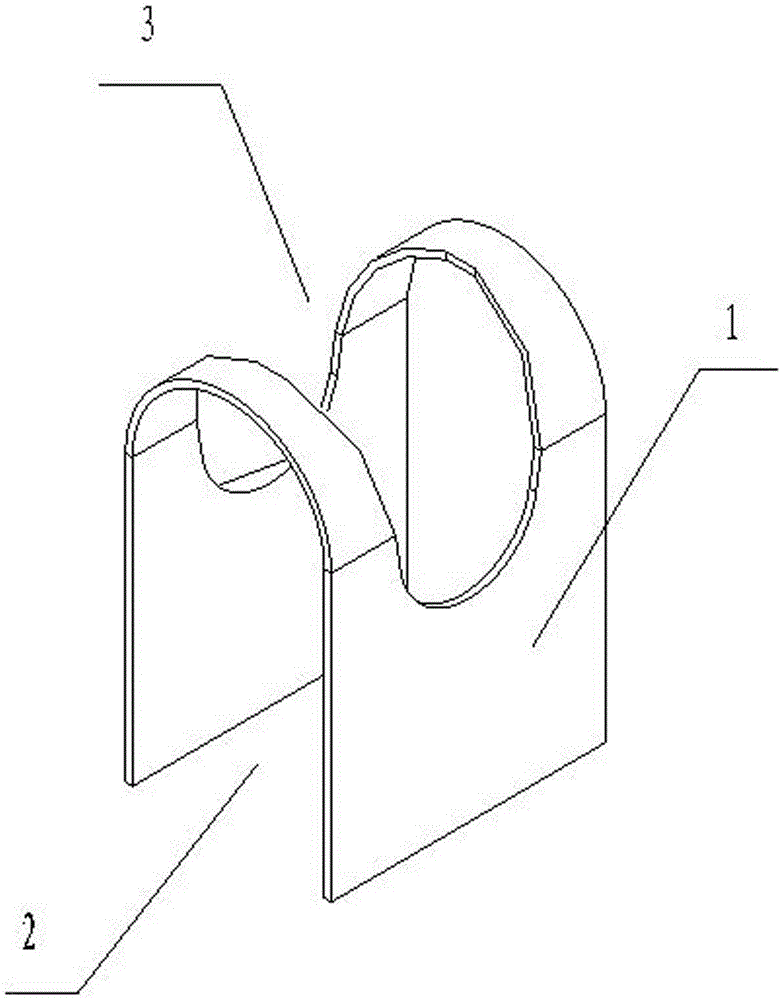

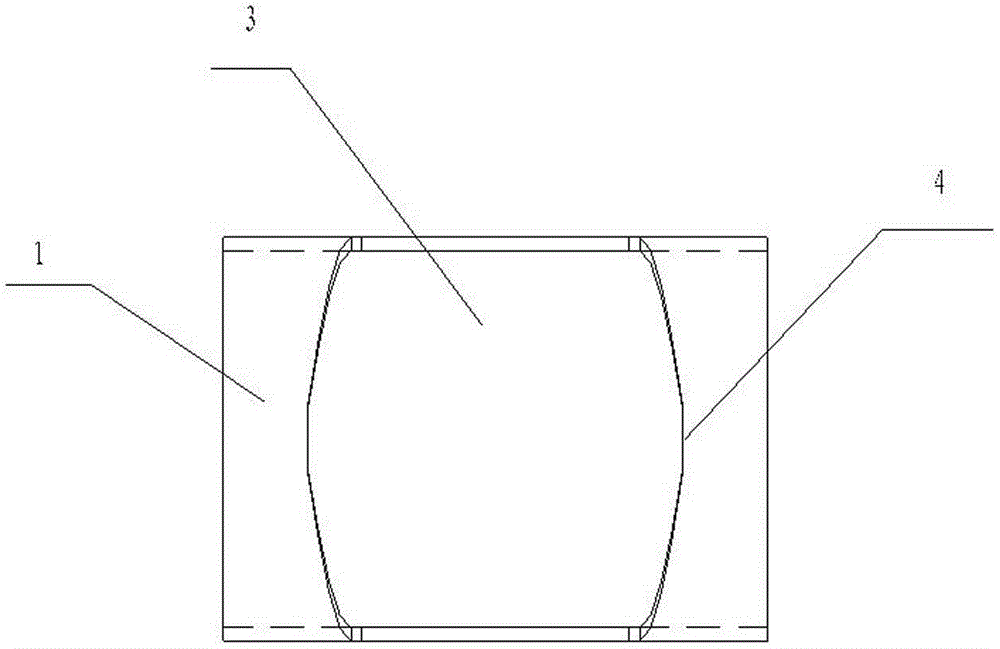

[0015] see figure 1 , a kind of orthogonal reinforcement positioning piece of the present embodiment, it comprises the positioning steel sheet 1 that is used for spot welding on the orthogonal steel bar of grid frame, and described positioning steel sheet 1 is bent to be U-shaped, and the development plane of positioning steel sheet 1 Rectangular, set the diameter of the orthogonal reinforcing bar as D, the radius of the orthogonal reinforcing bar as R, the thickness of the positioning steel sheet 1 is D / 25 of the diameter of the reinforcing bar to be fixed, its length is 3D+лR, and its width is 2D.

[0016] In this embodiment, the width of the U-shaped opening 2 of the positioning steel sheet is equal to the diameter of the orthogonal steel bar, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com