Escape belt and high-altitude escape device

An escape device and webbing technology, applied in the field of high-altitude escape, can solve the problems of reduced bearing capacity, short service life, easy tearing, etc., and achieve the effect of safe use, easy promotion, and not easy to tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

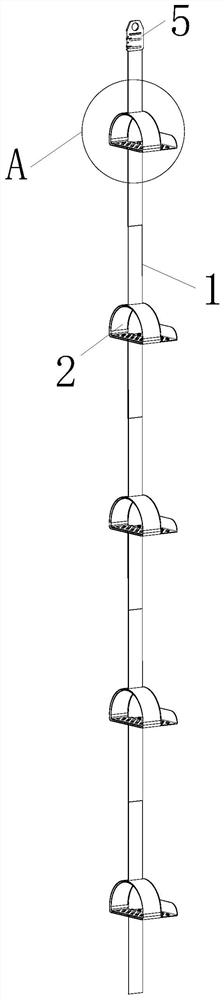

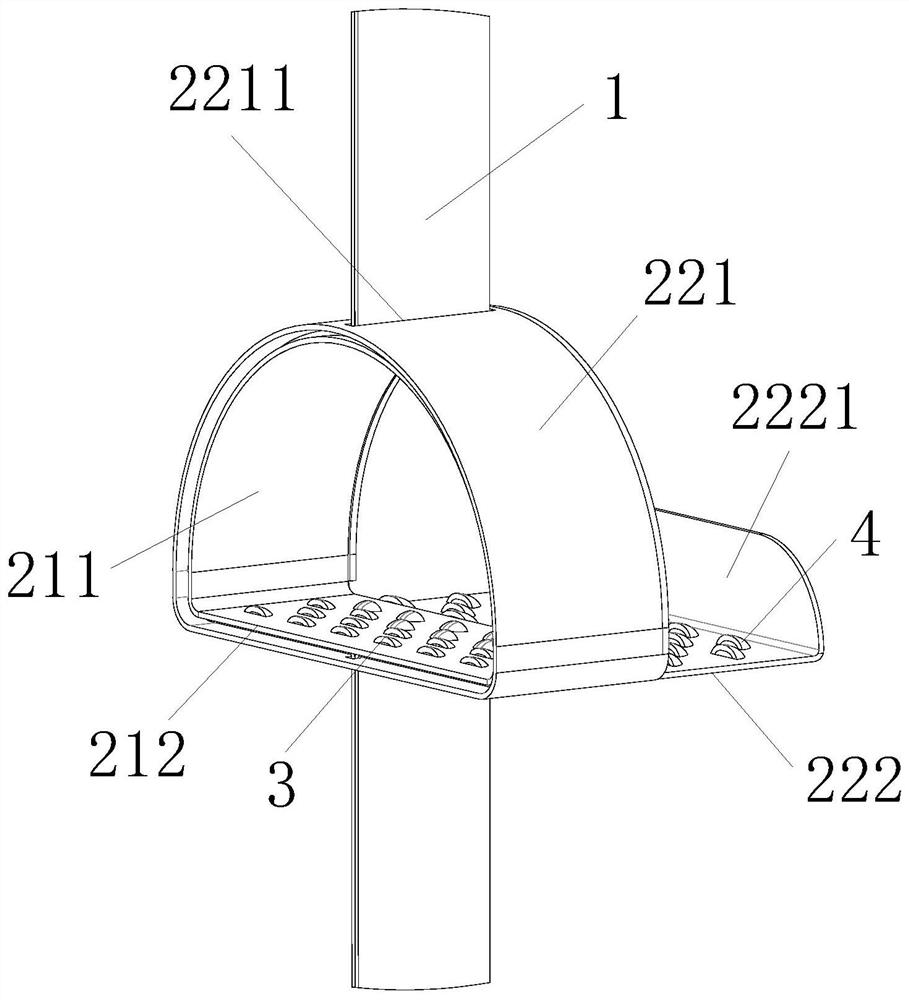

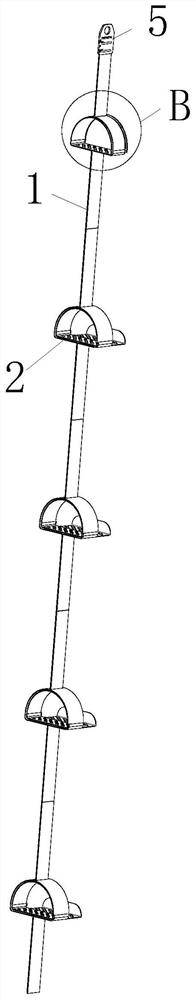

[0026] refer to Figure 1 to Figure 4 As shown, Embodiment 1 of the present invention provides an escape belt, which includes a webbing 1 and a pedal part 2. The webbing 1 is provided with a jumping part 12. The pedal part 2 includes a first cover and a second cover. The first cover The shell enters the gap portion 12 to stretch the gap portion 12, the second cover is covered on the first cover, and the non-gap portion 12 of the webbing 1 runs through the second case, which can be achieved without damaging the webbing 1. The connection between the ribbon 1 and the pedal part 2 is realized.

[0027] Under the situation based on this embodiment, the webbing 1 includes an even number of webbing monomers 11, the even number of webbing monomers 11 are equally divided into two groups, the webbing monomers 11 of the two groups are superimposed and fixed, and the webbing monomers 11 of the two groups are provided with There is a gap 12, and the number of webbing monomers 11 in each g...

Embodiment 2

[0038]Embodiment 2 of the present invention provides a high-altitude escape device, which includes the escape belt in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com