Device and method for detecting compressive strength of concrete through shearing-press method

A compressive strength, concrete technology, applied in the direction of using a stable shear force to test the strength of materials, can solve the problems of high requirements on the surrounding environment, affecting the bearing capacity of the structure, large damage surface, etc. Simple, intuitive test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

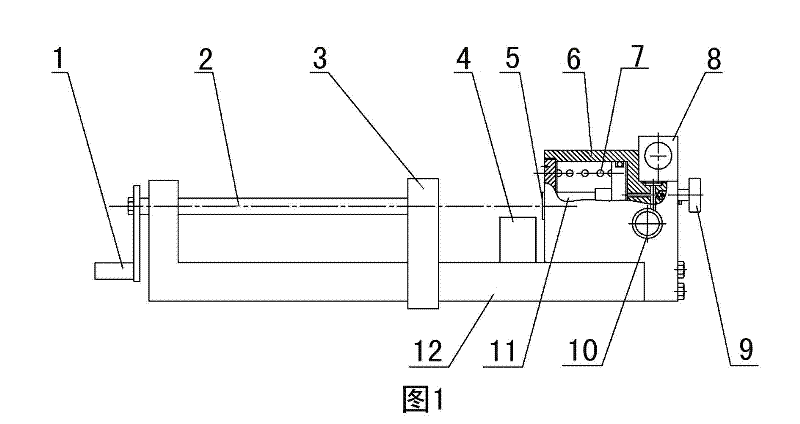

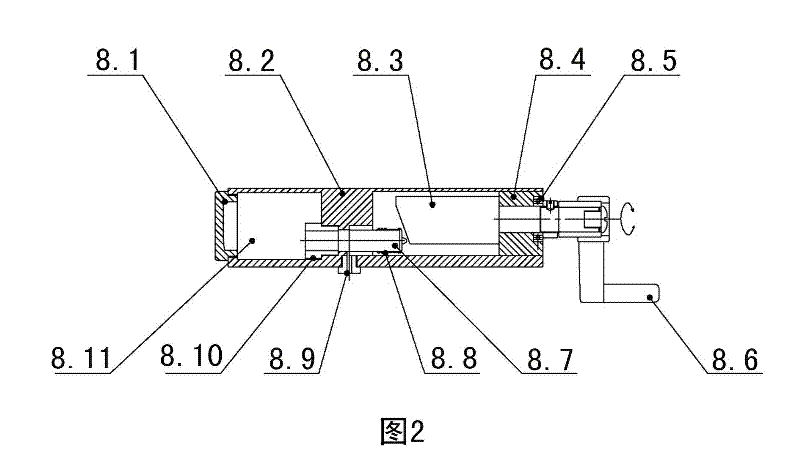

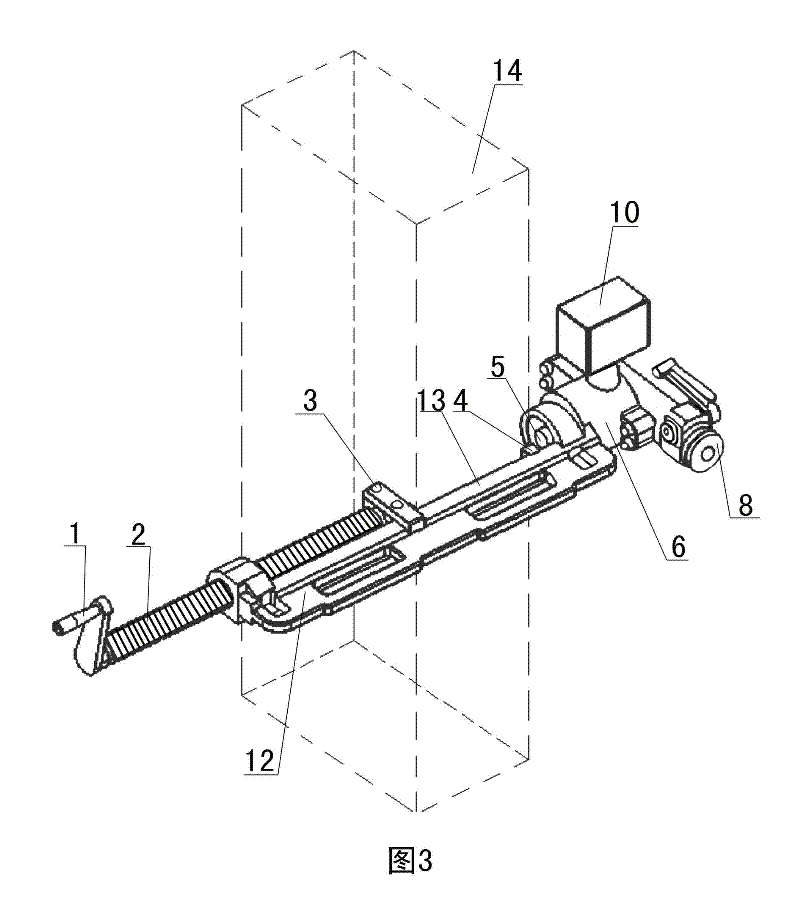

[0019] Examples see figure 1 , image 3 As shown, a device for detecting the compressive strength of concrete by the shear compression method includes a U-shaped base frame 12, a pressure-bearing plate 3 slidingly connected to the middle of the U-shaped base frame 12, and passes through one end of the U-shaped base frame 12 and connects the pressure-bearing The screw rod 2 of the plate 3, the rocker 1 connected to the end of the screw rod 2, the pressurized oil cylinder 6 is connected to the other end of the U-shaped base frame 12, and the pressurized oil cylinder 6 has a piston rod 11 and a return spring 7. The front end of the piston rod 11 of the oil cylinder 6 is connected with a pressure head 5, the pressure head 5 is opposite to the pressure bearing plate 3, the cross-sectional area of the pressure head 5 is smaller than the area of the pressure bearing plate 3, and the concrete member 14 to be tested is fixed on the pressure bearing plate 3 Between the pressure he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com