Polyphenyl insulation board

A thermal insulation board and polystyrene technology, applied in the direction of thermal insulation, building components, etc., can solve the problems of poor crack resistance, poor thermal insulation performance of thermal insulation boards, poor compressive performance, etc., and achieve high compressive strength and superior water resistance , Excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

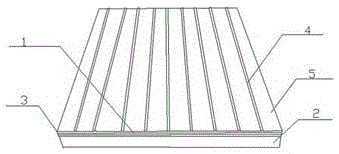

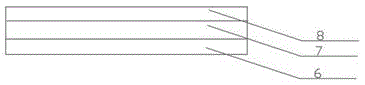

[0014] Such as figure 1 , figure 2 As shown, a polystyrene insulation board includes a board body 1; the board body 1 is provided with an upper cover plate 5, and the upper cover plate is provided with a reinforcing unit 4; The base plates 2 are connected; the upper cover plate 5 is provided with an insulating layer 6, the insulating layer 6 is provided with a reinforcing layer 7, and the reinforcing layer 7 is provided with an anti-crack layer 8; the insulating layer 7 is made of polystyrene , cement and superglue; the reinforcing layer 8 is made of reinforcing fiber and superglue; the anti-cracking layer 8 is made of anti-cracking agent; the thickness ratio of the upper cover plate 5 and the base plate 2 is 5: 1.

[0015] The invention has many advantages such as excellent thermal insulation performance, extremely high compressive strength, good c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com