A kind of permanent antibacterial polymer composite material and preparation method thereof

A composite material and polymer technology, applied in the direction of single-component synthetic polymer rayon, hollow filament manufacturing, textile and paper making, etc. Good electrochemical and thermal stability, good bactericidal and bacteriostatic effects, low vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

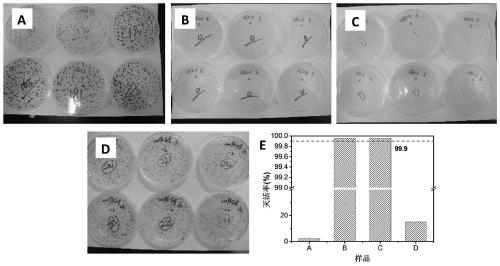

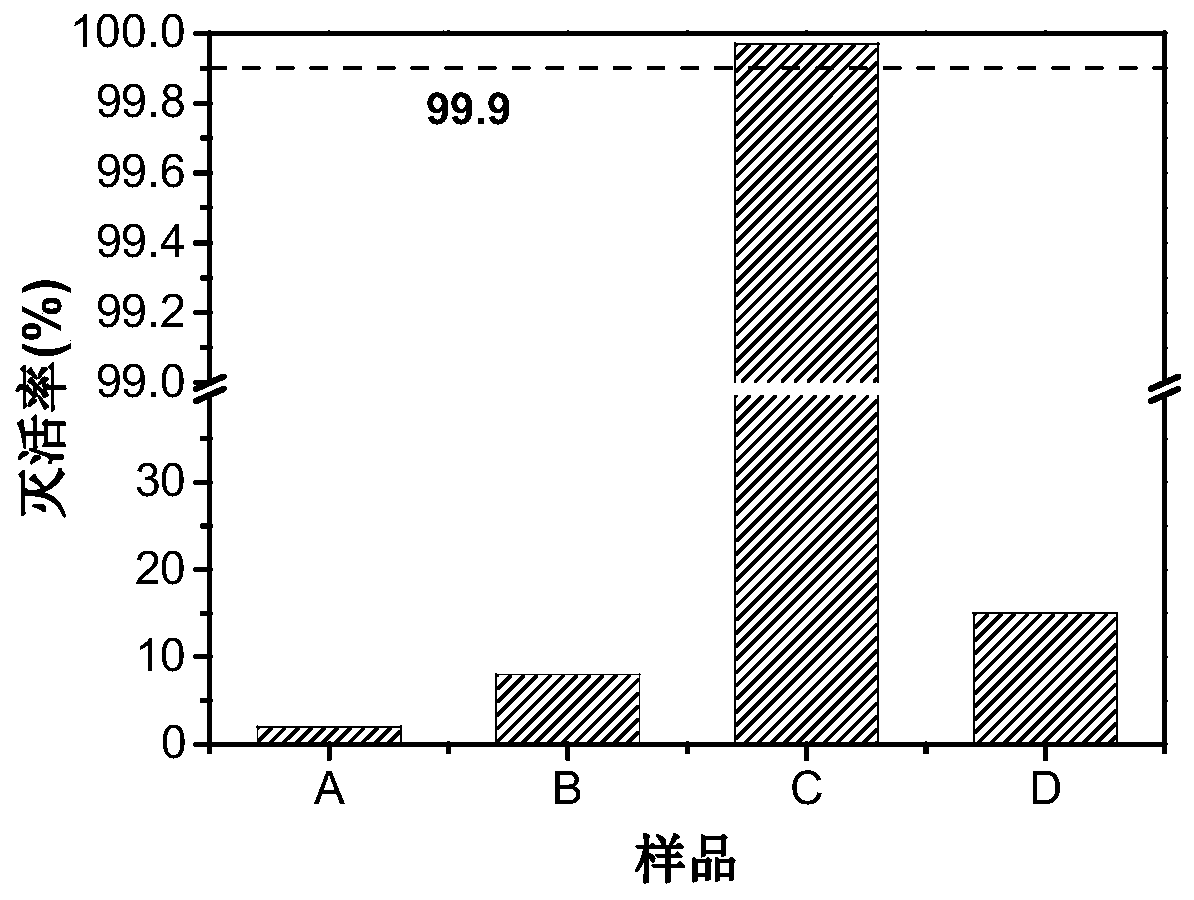

Examples

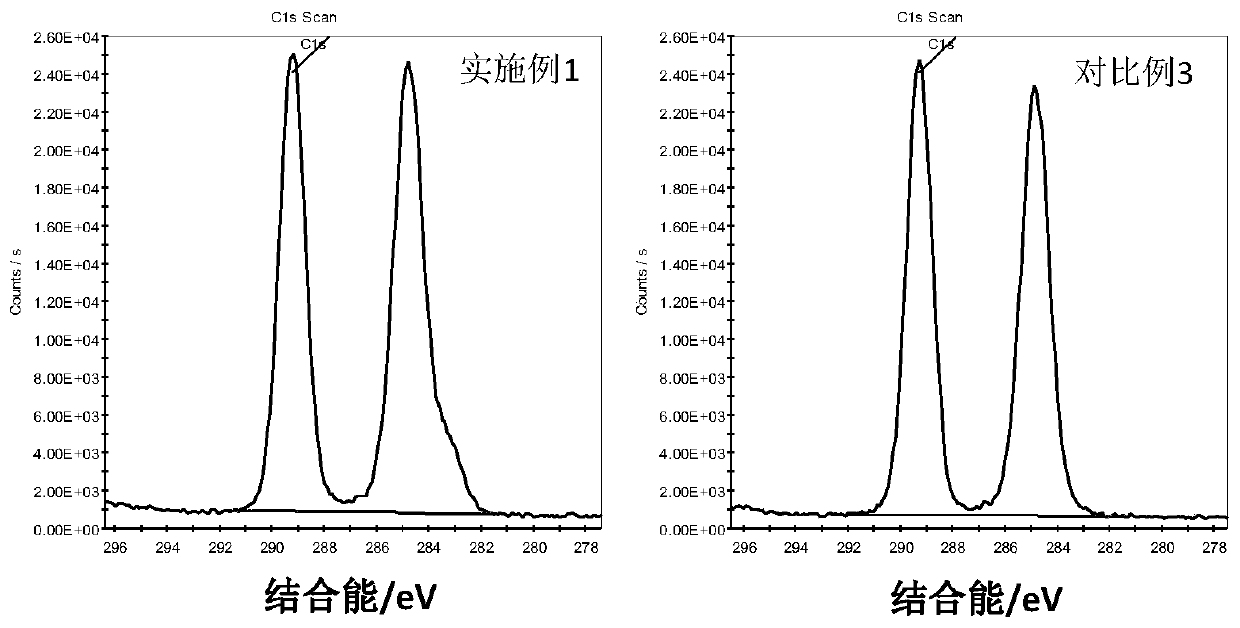

Embodiment 1

[0053] Step (1) First, add 100g of PVDF and 0.001g of 1-vinyl-3-propyl imidazolium bromide into the melt blending equipment, the temperature is 200°C, the rotation speed is 20rpm / min, and the mixing time is 1min; When the rotating speed is 60rpm, the mixing time is 5min. Then the material is discharged to obtain a blend of PVDF and IL, which is recorded as a PVDF / IL (100 / 0.001) blend.

[0054] Step (2) Put the above-mentioned PVDF / IL (100 / 0.001) film into a polyethylene ziplock bag. In electron beam irradiation, irradiation at normal temperature was performed at an irradiation dose of 20 kGy.

[0055] Step (3) directly press-molding the grafted blend obtained by the above-mentioned irradiation to obtain an antibacterial polymer composite membrane, the molding temperature is 200° C., the pressure is 15 MPa, the pressure is maintained for 2 minutes, and the thickness is 300 microns.

Embodiment 2

[0057] Step (1) First, add 100g of PVDF and 0.002g of 1-vinyl-3-propyl imidazolium bromide into the melt blending equipment, the temperature is 200°C, the rotation speed is 25rpm / min, and the mixing time is 1min; When the rotating speed is 50rpm, the mixing time is 6min. Then the material is discharged to obtain a blend of PVDF and IL, which is recorded as a PVDF / IL (100 / 0.002) blend.

[0058] Step (2) Put the above-mentioned PVDF / IL (100 / 0.002) film into a polyethylene ziplock bag. In electron beam irradiation, irradiation at normal temperature was performed at an irradiation dose of 25 kGy.

[0059] Step (3) directly press-molding the graft blend obtained by the above-mentioned irradiation to obtain an antibacterial polymer composite film, the molding temperature is 190° C., the pressure is 15 MPa, the pressure is maintained for 2 minutes, and the thickness is 300 microns.

Embodiment 3

[0061] Step (1) First, add 100g of PVDF and 0.04g of 1-vinyl-3-propyl imidazolium bromide into the melt blending equipment, the temperature is 190°C, the rotation speed is 20rpm / min, and the mixing time is 1min; When the rotating speed is 60rpm, the mixing time is 5min. Then discharge, to obtain a blend of PVDF and IL, denoted as PVDF / IL (100 / 0.04) blend.

[0062] Step (2) Put the above-mentioned PVDF / IL (100 / 0.04) film into a polyethylene ziplock bag. In electron beam irradiation, irradiation at normal temperature was performed at an irradiation dose of 50 kGy.

[0063] Step (3) directly press-molding the grafted blend obtained by the above-mentioned irradiation to obtain an antibacterial polymer composite membrane at a molding temperature of 195° C., a pressure of 10 MPa, a pressure hold of 2 minutes, and a thickness of 300 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com