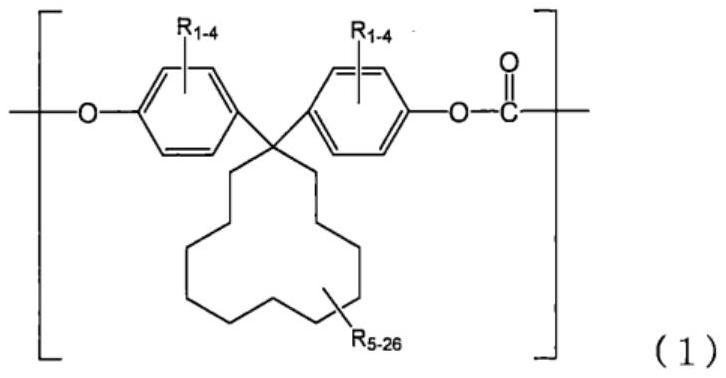

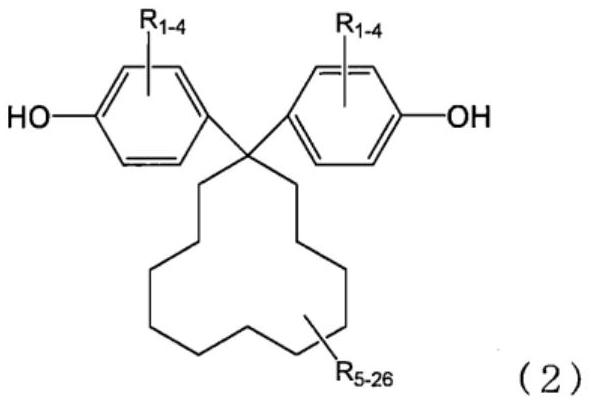

Polycarbonate resin and method for producing same

A technology of polycarbonate resin and manufacturing method, which is applied in the field of polycarbonate resin and its manufacturing, can solve problems such as cumbersome operation, and achieve the effect of less mold pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to the following Example.

[0129]

[0130] The weight-average molecular weight (Mw), molecular weight distribution value (Mw / Mn) (in terms of polystyrene) and oligomers with a molecular weight of less than 1,000 of the polycarbonate resins obtained in Examples and Comparative Examples were measured under the following conditions The content ratio (mass %).

[0131] Machine used: HLC-8320GPC manufactured by Tosoh Corporation

[0132] Chromatographic column: Shodex K-G+K-805Lx2 pieces+K-800D

[0133] Eluent; Chloroform

[0134] Temperature: chromatographic column constant temperature tank 40°C

[0135] Flow rate: 1.0ml / min

[0136] Concentration: 0.1wt / vol%

[0137] Injection volume: 100μl

[0138] Pre-treatment: filter with 0.45μm filter

[0139] Detector: Differential Refractometer (RI)

[0140] In addition, the content rate (mass %) of the oligomer wit...

Embodiment 2

[0153] In the process 2, except having changed emulsification time into 2 minutes, it carried out similarly to Example 1, and obtained the polycarbonate resin powder.

[0154] As a result of GPC analysis and measurement of the obtained polycarbonate resin powder, the Mw was 157,500, the molecular weight distribution value (Mw / Mn) was 4.16, and the content ratio of oligomers with a molecular weight of less than 1,000 was 0.35% by mass.

Embodiment 3

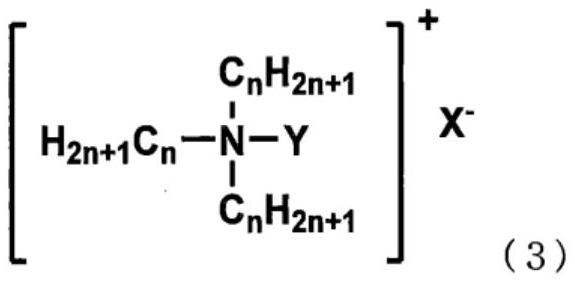

[0156] In the process 1, except having changed TEBAC into tributylbenzyl ammonium chloride (TBBAC), it carried out similarly to Example 1, and obtained the polycarbonate resin powder.

[0157] As a result of GPC analysis and measurement of the obtained polycarbonate resin powder, the Mw was 159,300, the molecular weight distribution value (Mw / Mn) was 4.94, and the content ratio of oligomers with a molecular weight of less than 1,000 was 0.27% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com