Surface protective coating for alloy zippers, buttons and hardware products

A protective coating and zipper technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of anti-ultraviolet light weak yellowing, low transparency and opacity, raw materials are easy to dry and thicken, and achieve stable quality and not easy to evaporate And volatilization, the effect of solving the problem of low transparency and opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

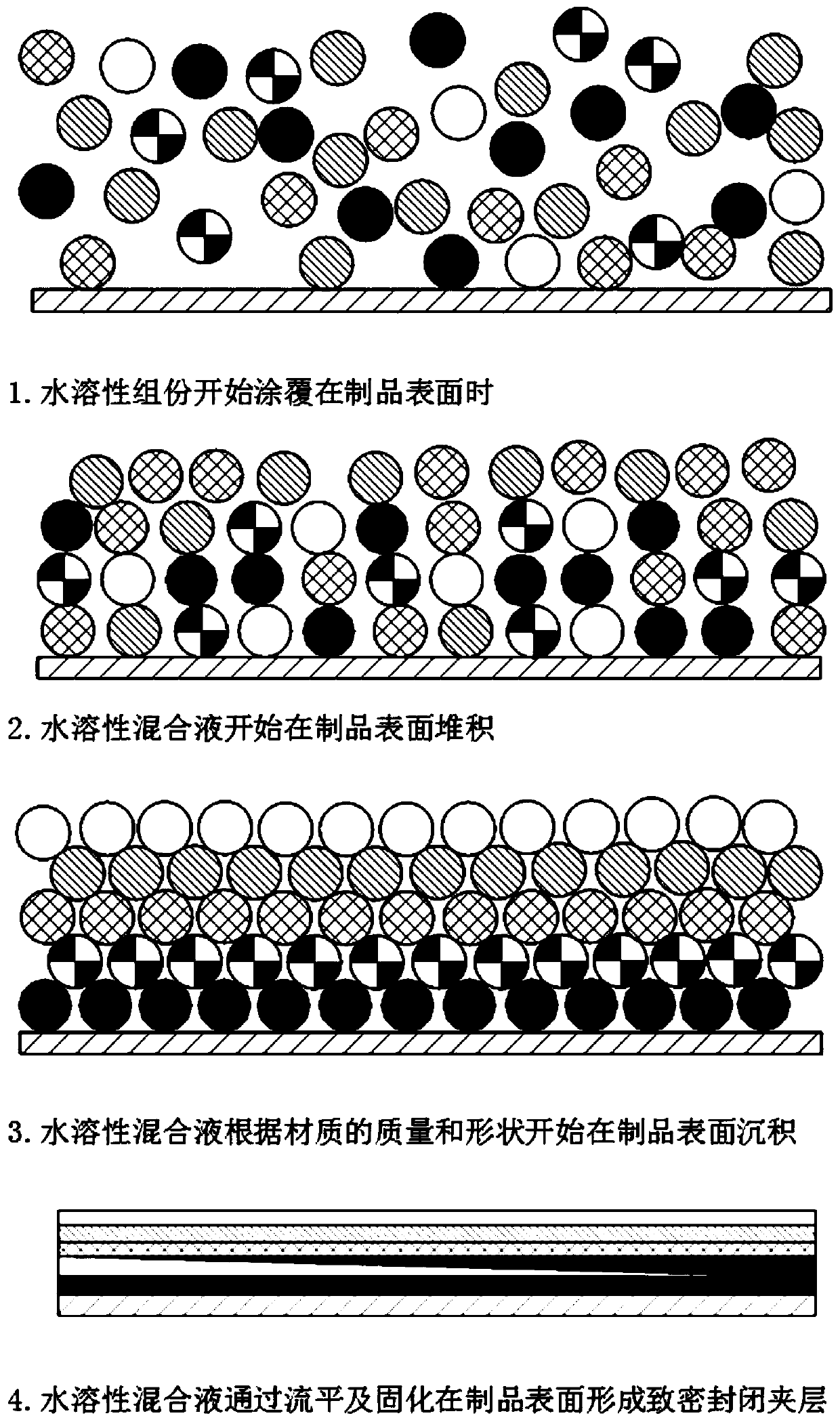

[0020] according to figure 1 As shown, the present embodiment provides a surface protection coating for alloy zipper button hardware products, and the quality components of the surface protection coating include:

[0021] The first component: 5-12 parts of sodium silicate / potassium silicate solution

[0022] The second component: 5-12 parts of acrylic emulsion

[0023] The third component: deionized water balance

[0024] The sodium silicate / potassium silicate solution in the first component and the acrylic acid emulsion in the second component are water-soluble materials capable of curing at low temperature. The second composition also includes the following quality components:

[0025]

[0026]

[0027] Use the above formula as the sealing coating on the surface material of alloy clothing luggage hardware (containing zinc alloy plated alloy surface):

[0028] Among them, potassium silicate / sodium silicate is the basic material for increasing the hardness and transp...

Embodiment 2

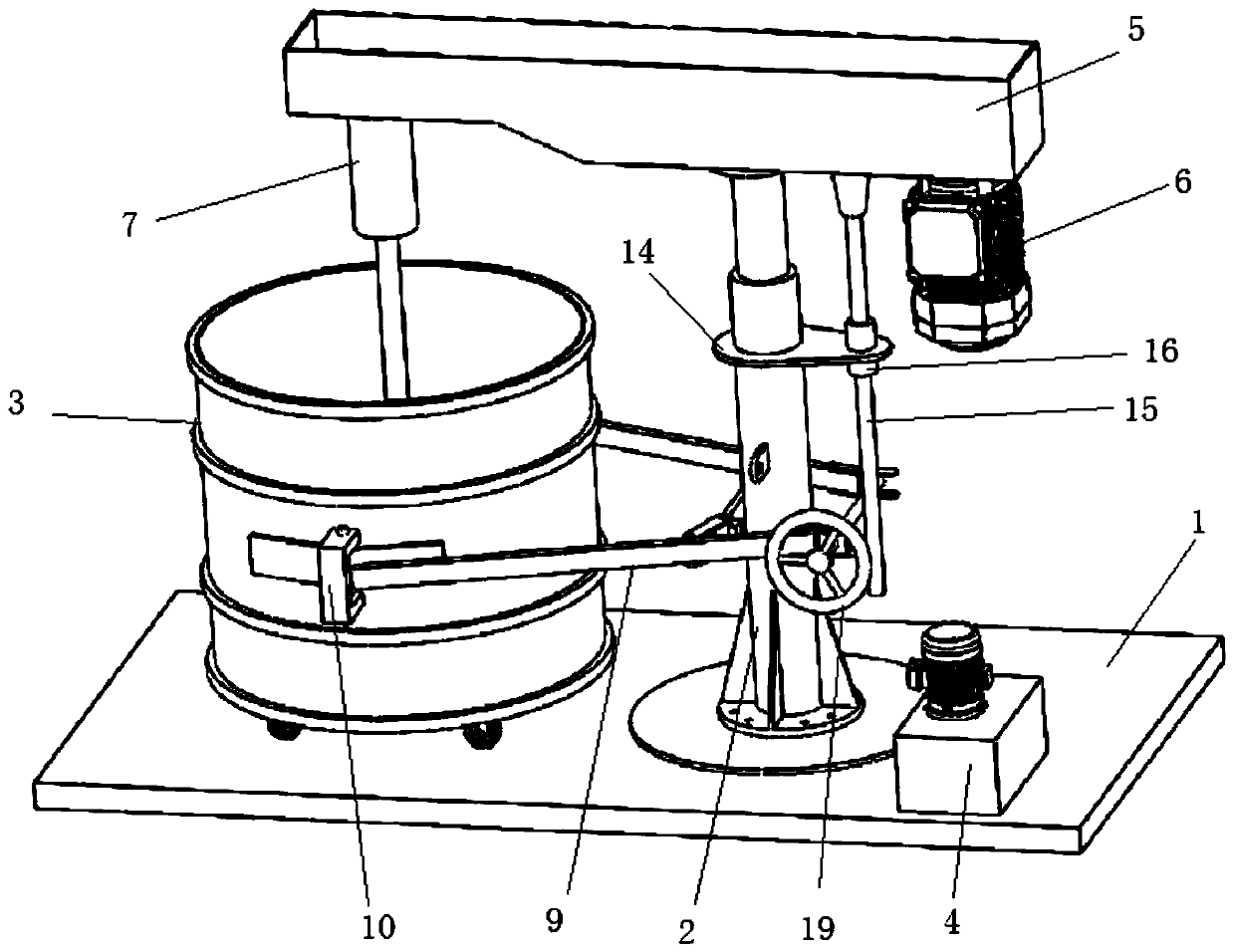

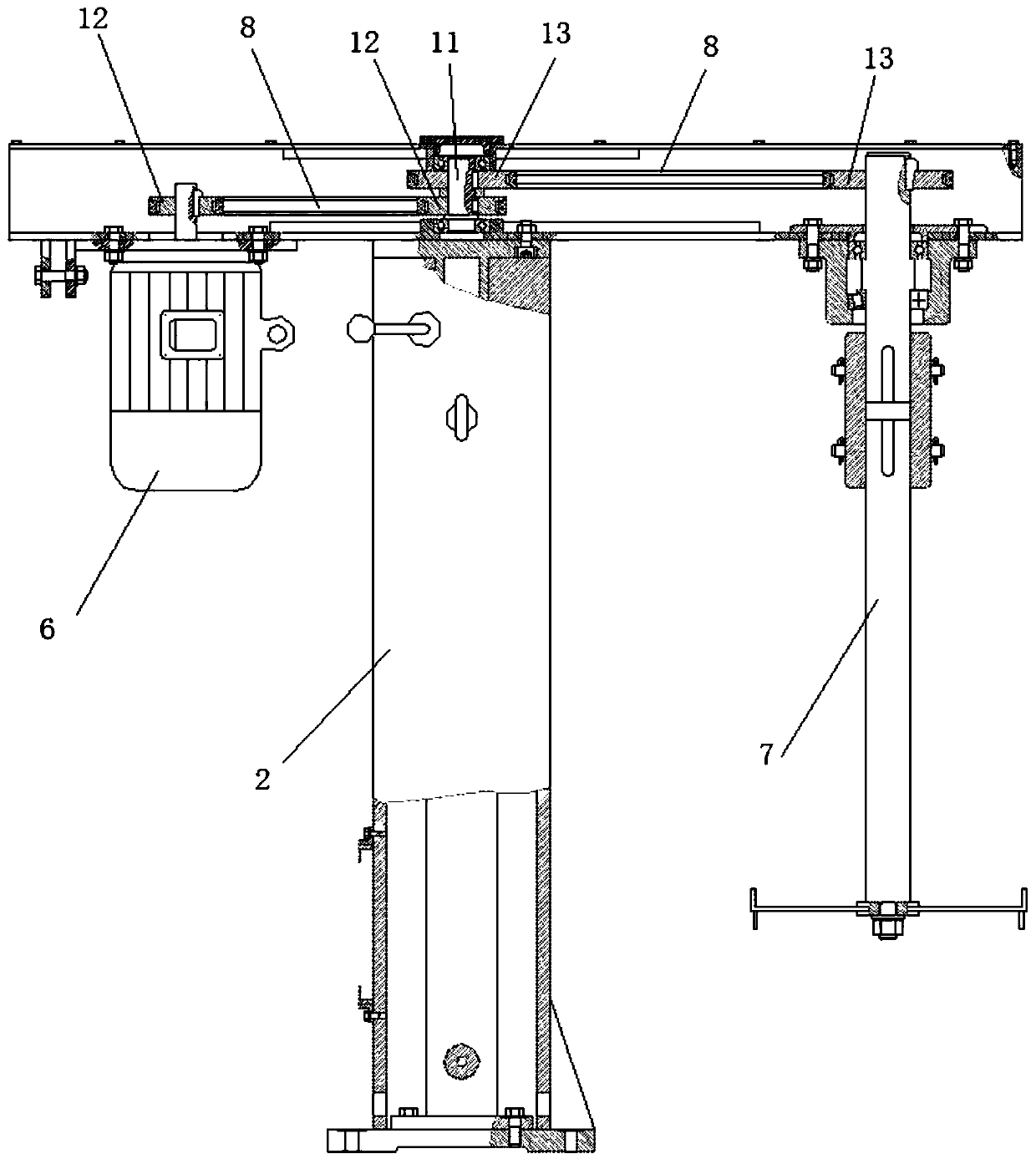

[0043] When used on the surface of the zipper, it adopts the form of continuous coating with the roller, and the roller carries the solution to continuously roll and adhere to the zipper teeth, and then introduces it into the oven to form a one-stop production of rolling coating, baking, and cooling. Under this process condition, the zipper is processed Continuous coating, simple process, controllable conditions, fast film formation, good adhesion, uniform coating, and good wear resistance.

Embodiment 3

[0045] When used on the surface of zipper pullers and small hardware, it is realized by spraying. The mixed liquid is driven by compressed air in a high-pressure spray tank, and is quickly overlapped and coated on the surface of the product in the form of dot splashes, forming a multi-layer seal before entering the oven. to cure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com