A foaming structure of a non-sewing one-piece face cover and its preparation mold and preparation method

A foaming mold, one-piece technology, applied in seat covers, transportation and packaging, special positions of vehicles, etc., can solve the problems of difficult positioning of foaming molds and face covers, frequent appearance problems, and high labor costs. Personalized customization requirements, reduced sewing costs, and the effect of zero error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

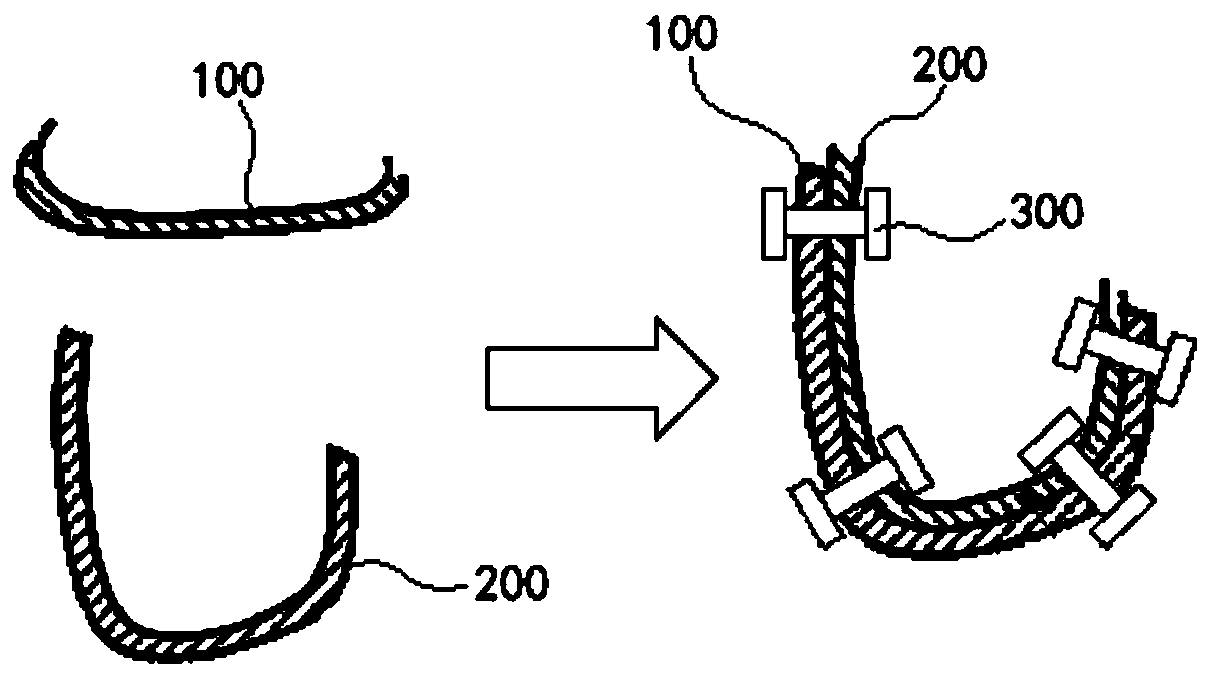

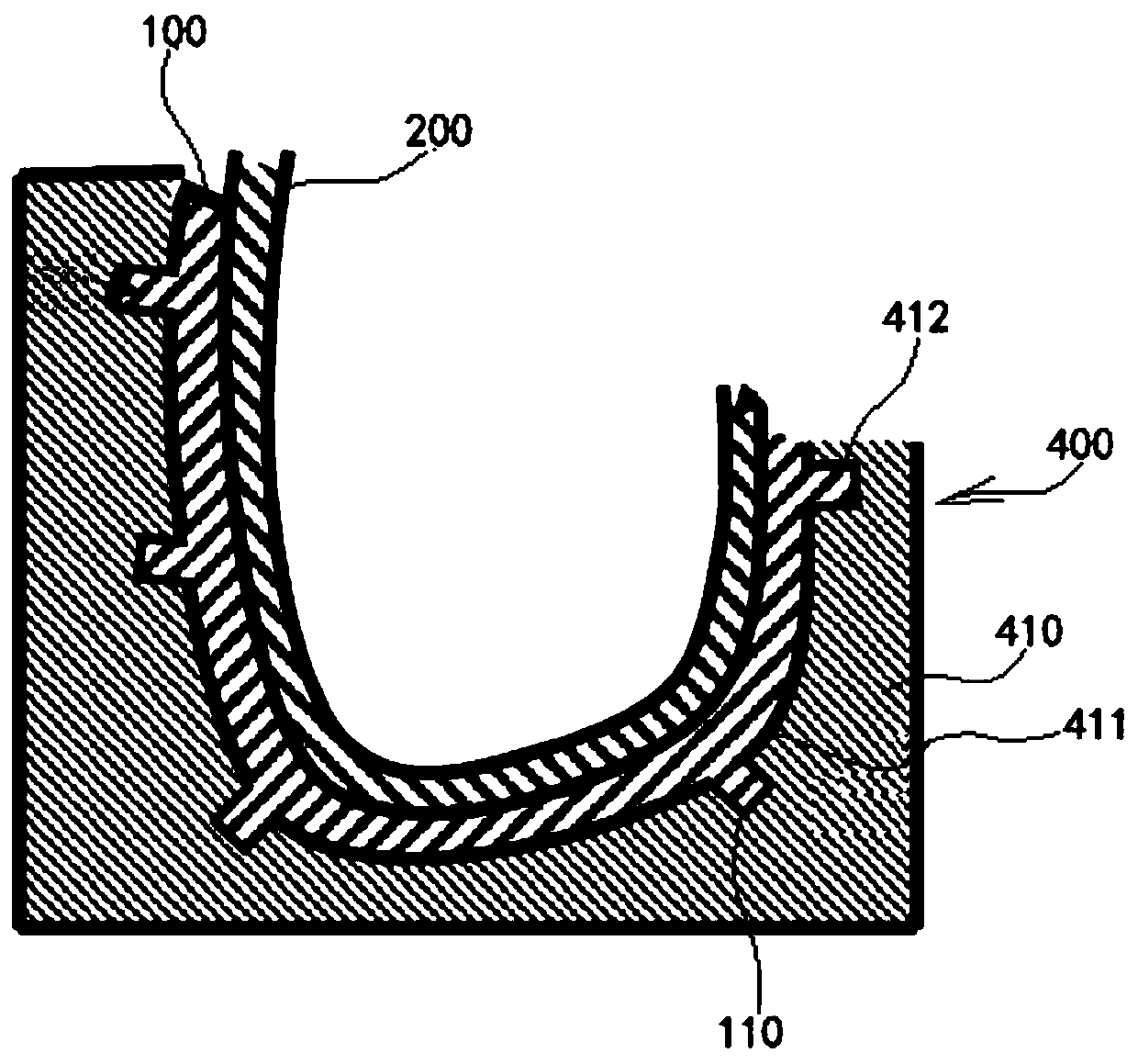

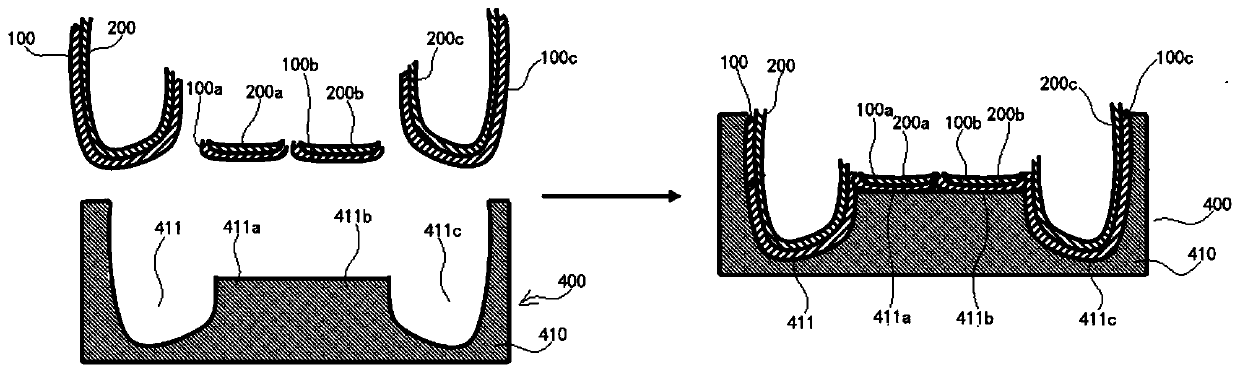

[0075] see Figure 1 to Figure 5 , the preparation process of the one-piece mask foam structure product of this embodiment is as follows:

[0076] 1) Prepare a number of concave molds 100 with a thickness of 3 to 5 mm according to the profile requirements of the side of the foam facing the occupant (hereinafter referred to as the A side of the foam);

[0077] 2) According to the profile requirements of the surface A of the foam body, several pieces of surface covering pieces 200 are cut;

[0078] 3) Place each block face cover cut piece 200 in the corresponding die 100 and use several I-shaped label nails 300 for positioning; the edges of the block face cover cut pieces 200 are all higher than the corresponding die 100 edge 5 ~10mm.

[0079] When using several I-shaped label nails 300 for positioning, punch holes at the key positions of the die 100 (positions with larger arcs, upper edge positions), select suitable sized javelins and I-shaped label pins 300, and the diameter...

Embodiment 2

[0085] see Image 6 , the difference between the preparation process of the integrated face cover foam structure product of this embodiment and embodiment 1 is that: the positioning between the block face cover cut piece 200 and the die 100 is positioned by glue, that is, inside the die 100 Apply a layer of adhesive film 310 (the adhesive film 310 is not easy to remain on the surface of the block face cover cut piece 200), put the block face cover cut piece 200, close the mold and start foaming, take out the product , removing the adhesive film 310 so as not to affect the appearance of the product. The remainder of this embodiment is the same as embodiment 1.

Embodiment 3

[0087] see Figure 7 , the difference between the preparation process of the integrated face cover foam structure product of this embodiment and embodiment 1 is that: the positioning between the block face cover cut piece 200 and the die 100 adopts several iron powder sheets 320 and some magnets 330 Positioning is carried out, wherein the magnet 330 is arranged on the die 100, and the iron powder sheet 320 is arranged on the block face cover cutting sheet 200. The specific method is to install a magnet 330 at the key position of the die 100 (the position where the radian is larger, the upper edge position), and when placing the block face cover cut piece 200, stick an iron on the back side of the block face cover cut piece 200 at the corresponding position. The powder sheet 320 fixes the block face cover cut piece 200 and the die 100 . The remainder of this embodiment is the same as embodiment 1.

[0088] The positioning between the block face cover cutting piece 200 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com