Method and device for cutting metal-moulded honeycomb thin wave plate

A metal forming and cutting device technology, applied in shearing devices, metal processing equipment, shearing machine equipment, etc., can solve the problems of oblique cutting of the angle of the uncut end face, not suitable for cutting the corrugated plate, unable to cut the corrugated plate, etc. Low equipment requirements, uniform force and small cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

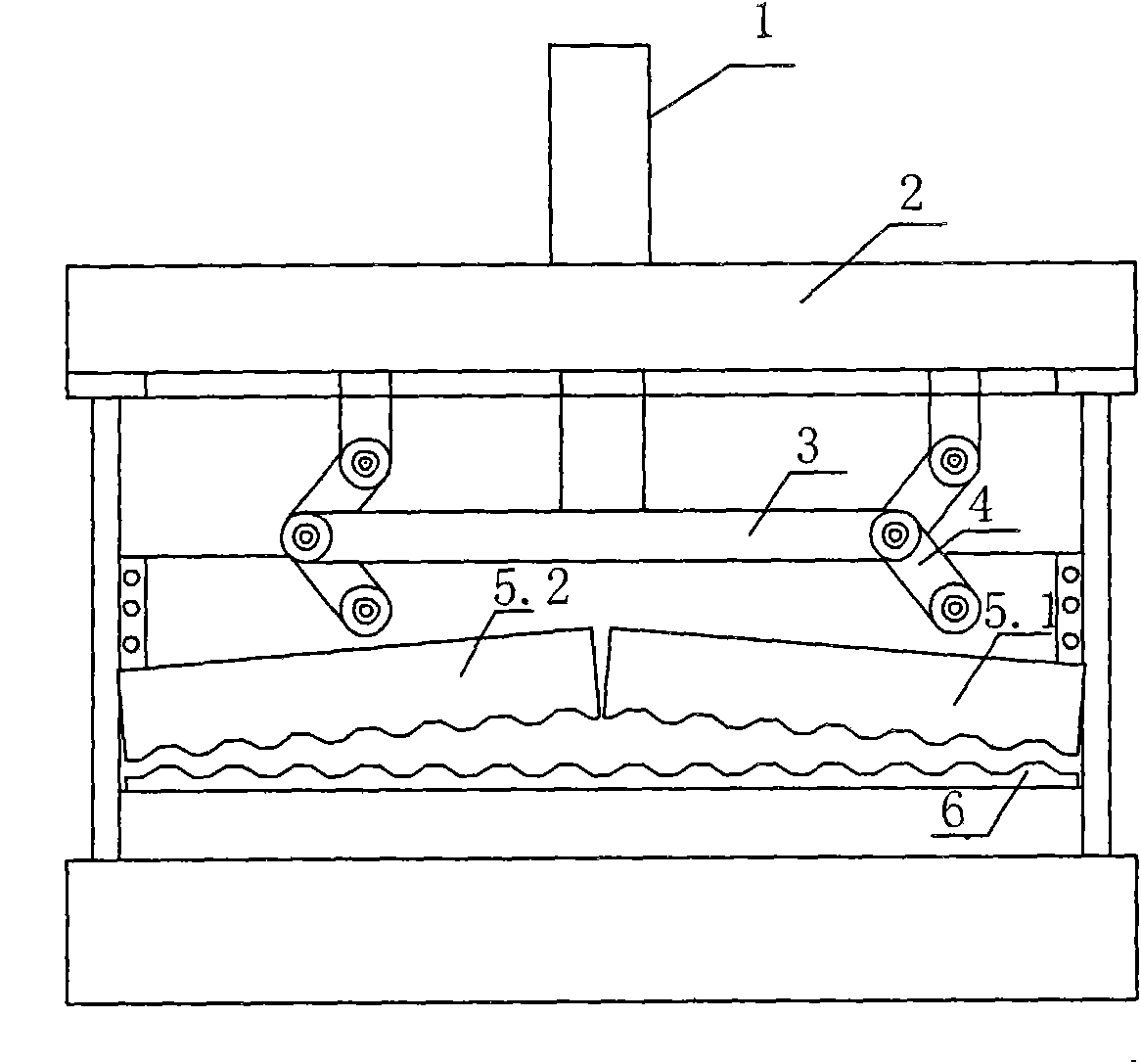

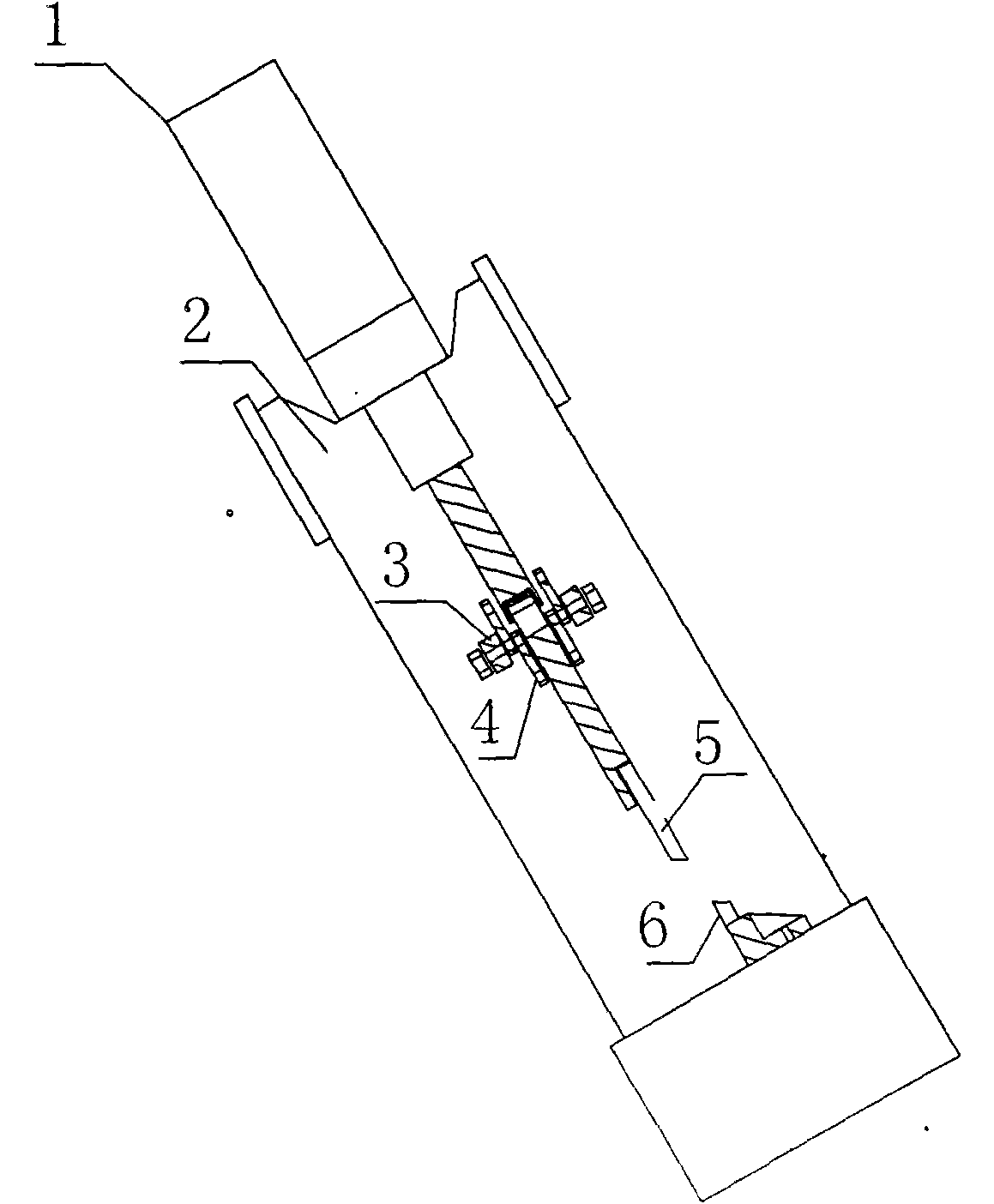

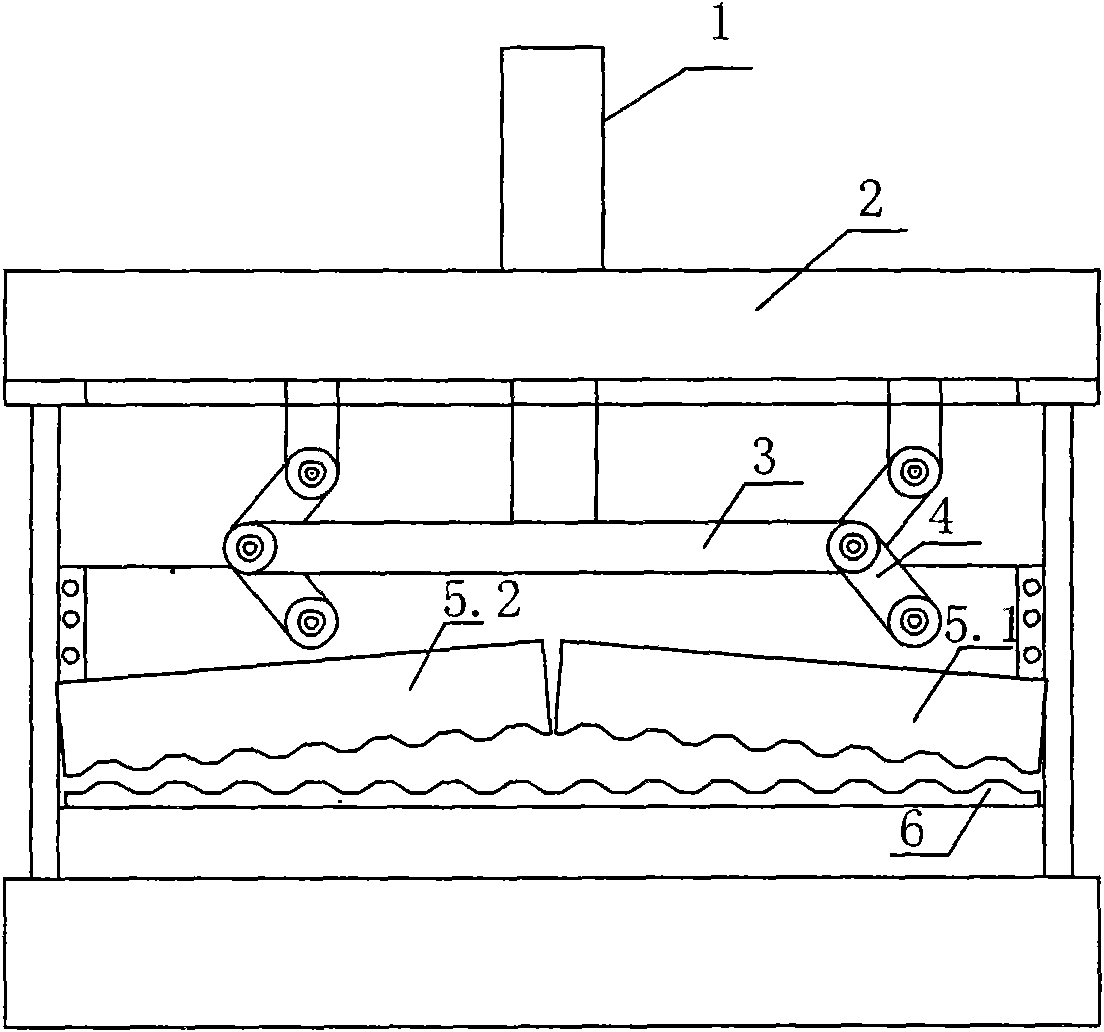

[0020] Embodiment: referring to the drawings, the punching and cutting device of the present invention that cuts both sides to the middle at the same time in a shearing manner includes a rectangular frame 2 that fixes the upper and lower blade rows and the power. The upper beam of the frame is provided with a driving shear Hydraulic cylinder 1, the upper part of the frame has an upper knife rack that moves up and down to form a punching shear, and is limited by the left and right vertical rods on both sides of the frame. The upper knife rack is driven by the cylinder for punching and shearing movement, and the bottom is dislocated and fixed with the lower knife Row 6. The upper knife row has two left and right knife rows 5.1 and 5.2, which are fixed on the upper knife rack with a bottom angle of 10 degrees facing each other in an "eight" shape. The upper and lower knife rows have the same shape and complement each other as the cut honeycomb. Between the upper knife rack and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com