Field snail tail chopper with acute teeth and sharp mouth

A sharp-nosed and guillotine technology, applied in the field of food processing equipment, can solve the problems of low work efficiency, troublesome, long time spent, etc., and achieve the effects of high work efficiency, low cost and high cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

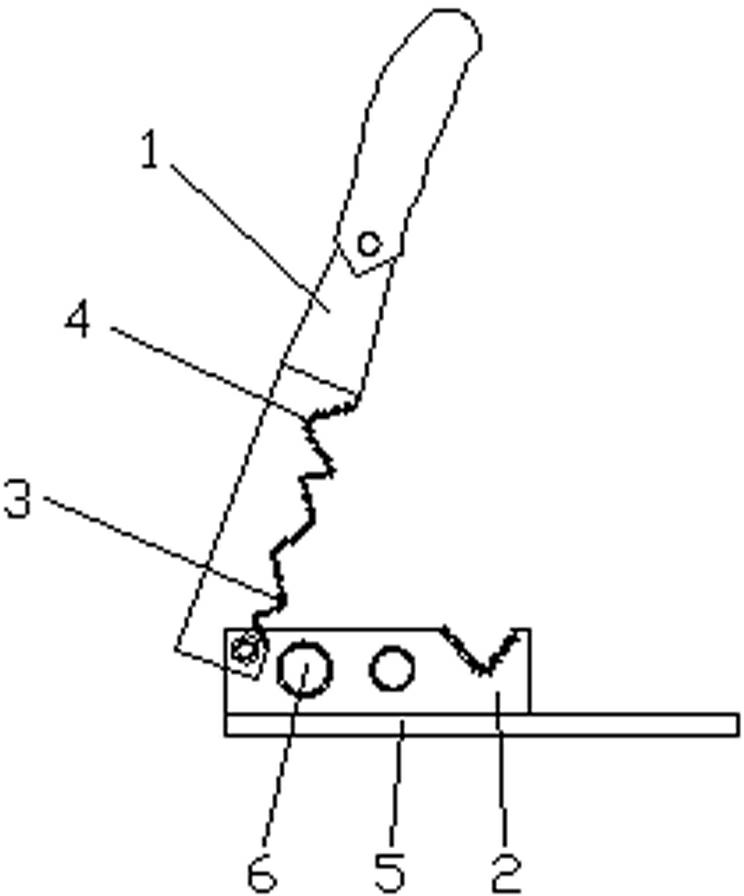

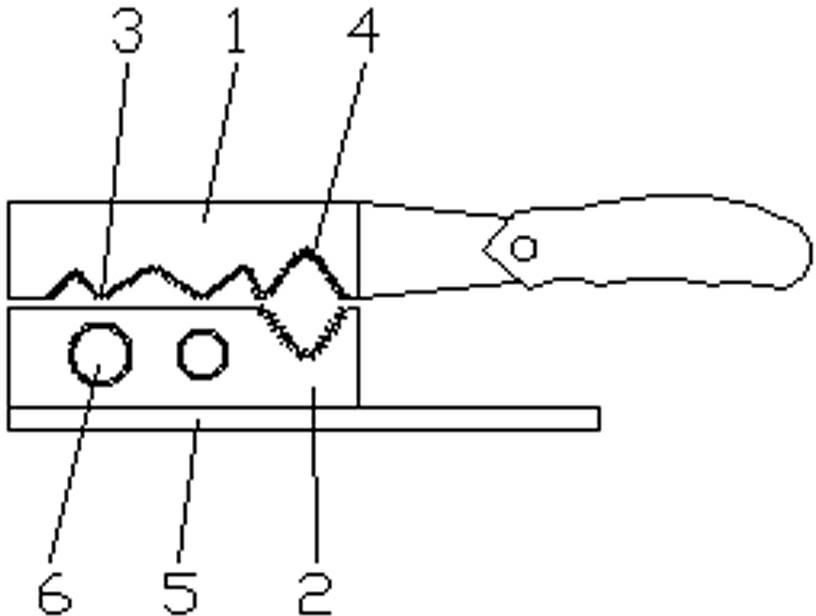

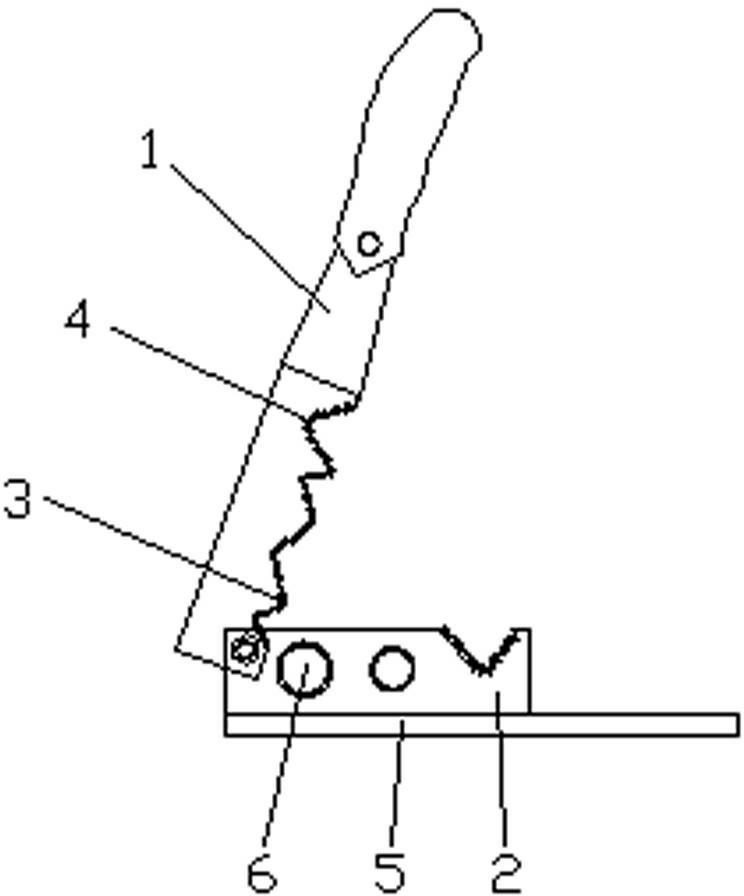

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] see figure 1 and figure 2 , a sharp-mouthed and sharp-tailed guillotine, comprising a movable guillotine 1 at the top and a fixed guillotine 2 at the bottom, one end of the movable guillotine 1 and one end of the fixed guillotine 2 are connected by bolts, and at the front end of the blade part of the movable guillotine There are several tooth tips 3, the rear end of the blade part is provided with a groove 4 with a gear mark, the fixed guillotine 2 is fixed by the fixing seat 5, and the fixed guillotine 2 is provided with a ring gear corresponding to the tooth tip 3 of the movable guillotine The hole 6 is provided with a groove 4 corresponding to the movable guillotine groove 4 with gear marks at the rear end of the fixed guillotine 2 .

[0013] The movable guillotine 1 is bolted with a handle for operation, and the tooth tips are canine-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com