Cutting method with auxiliary laser heating for metal strip

A metal strip, laser-assisted technology, used in laser welding equipment, metal processing equipment, accessories of shearing machines, etc., can solve problems such as inability to meet continuous and high-speed production requirements, and reduce wear and chipping risks. , The effect of reducing cutting force and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] High-strength steel, the laser is a semiconductor laser

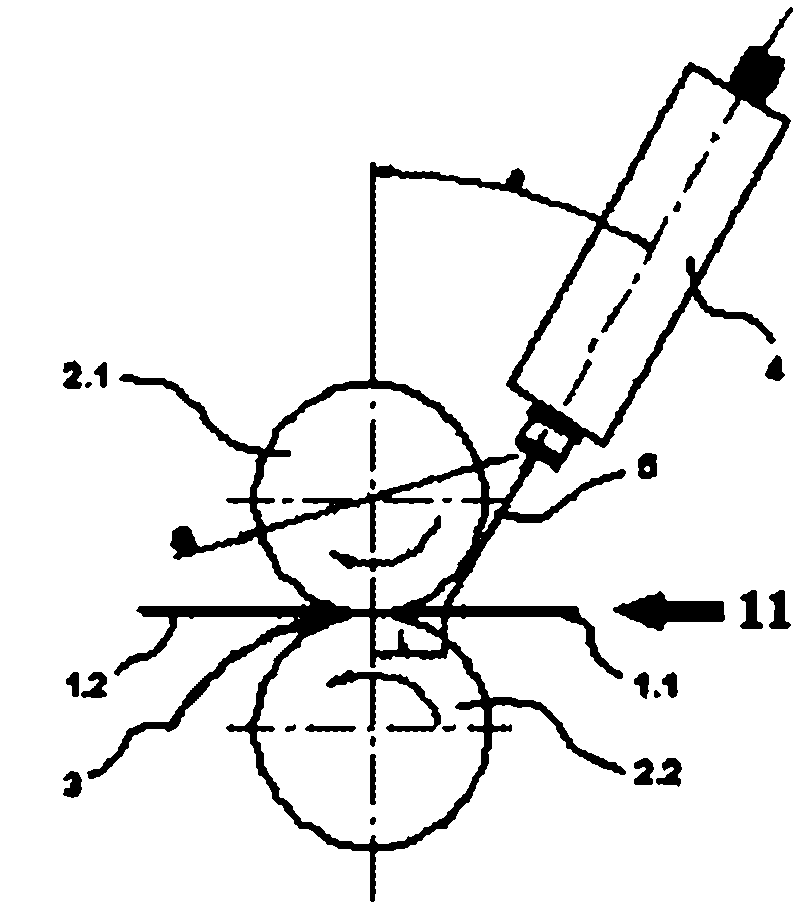

[0052] Please refer to attached drawings 1-3, the first step, according to the production characteristics of high-strength steel, the running speed U of the strip, the shape and area A of the laser spot can be given S , and the laser irradiation angle α.

[0053] U=80m / min

[0054] A S =1.2×2.0mm 2 =2.4mm 2 (Select a rectangular spot, the long side is the running direction of the strip)

[0055] (The surface morphology of high-strength steel is relatively poor, and the speed is slow)

[0056] The second step is to determine a0~a2, β and χ according to the surface morphology, thickness and laser wavelength of the metal strip.

[0057] Iron and steel materials, solid-state lasers, according to experiments;

[0058] a0=0.0741

[0059] a1=4.8e5

[0060] a2=-3.6e10

[0061] β=0.5

[0062] χ=-0.75

[0063] The third step is to determine the resistivity ρ of the strip and the correlation coefficients requi...

Embodiment 2

[0077] Silicon steel, the laser is a semiconductor laser

[0078] In the first step, according to the characteristics of silicon steel production, the running speed U of the strip, the shape and area A of the laser spot can be given S , and the laser irradiation angle α.

[0079] U=280m / min

[0080] A S =1.2×1.2mm 2 =1.44mm 2

[0081] α = 1 2 π

[0082] (The surface morphology of silicon steel is relatively good, and the speed is fast)

[0083] The second step is to determine a0~a2, β and χ according to the surface morphology, thickness and laser wavelength of the metal strip.

[0084] Iron and steel materials, solid-state lasers, according to experiments,

[0085] a0=0.0741

[0086] a1=4.8e5

[0087] a2=-3.6e10

[0088] χ=-0.75

[0089] The third step is to determine the resistivity ρ of the strip and the correlation coefficients required for temperature calculation, namely At and ξ, accor...

Embodiment 3

[0103] Stainless steel, the laser is a semiconductor laser

[0104] In the first step, according to the characteristics of stainless steel production, the running speed U of the strip, the shape and area A of the laser spot can be given S , and the laser irradiation angle α.

[0105] U=120m / min

[0106] A S =1.2×2.0mm 2 =2.4mm 2

[0107] (Stainless steel has good surface appearance and fast speed).

[0108] The second step is to determine a0~a2, β and χ according to the surface morphology, thickness and laser wavelength of the metal strip.

[0109] Iron and steel materials, solid-state lasers, according to experiments,

[0110] a0=0.0741

[0111] a1=4.8e5

[0112] a2=-3.6e10

[0113]χ=-0.75

[0114] The third step is to determine the resistivity ρ of the strip and the correlation coefficients required for temperature calculation, namely At and ξ, according to the thermal physical properties of the metal strip.

[0115] According to the material handbook, the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com