Patents

Literature

77results about How to "Reduce cutting load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

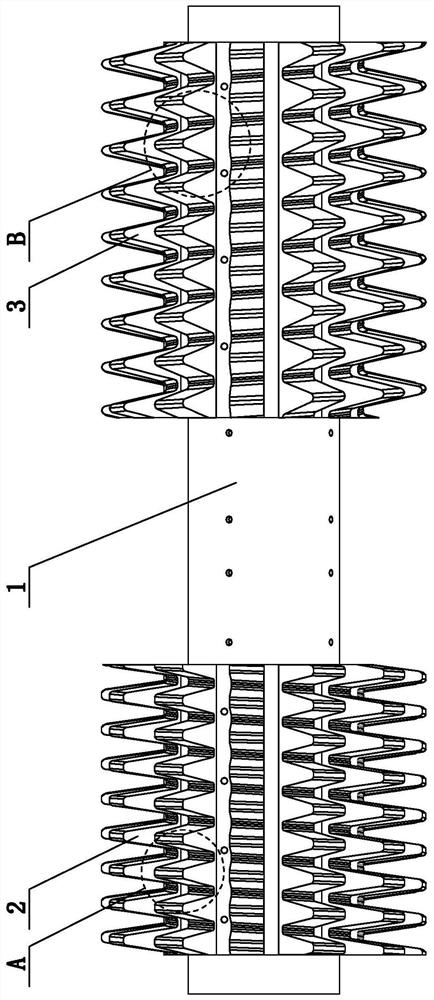

Sawing Yarn

InactiveUS20070261690A1Improve cutting performanceTrue cylindrical shapeAbrasion apparatusMetal sawing toolsFiberYarn

A sawing yarn comprises an abrasive mixture which contains a bonding resin and an abrasive material, as well as a multifilament core made of fibers which are resistant to breaking. The fibers are arranged substantially parallel to one another and are enveloped by the abrasive mixture. The bonding resin contains no polytetrafluoroethylene, and the quantity of abrasive material in the mixture gradually decreases from the surface of the abrasive yarn inward. The yarn is suitable for cutting hard and brittle materials such as single-crystal silicon.

Owner:SIA ABRASIVES IND

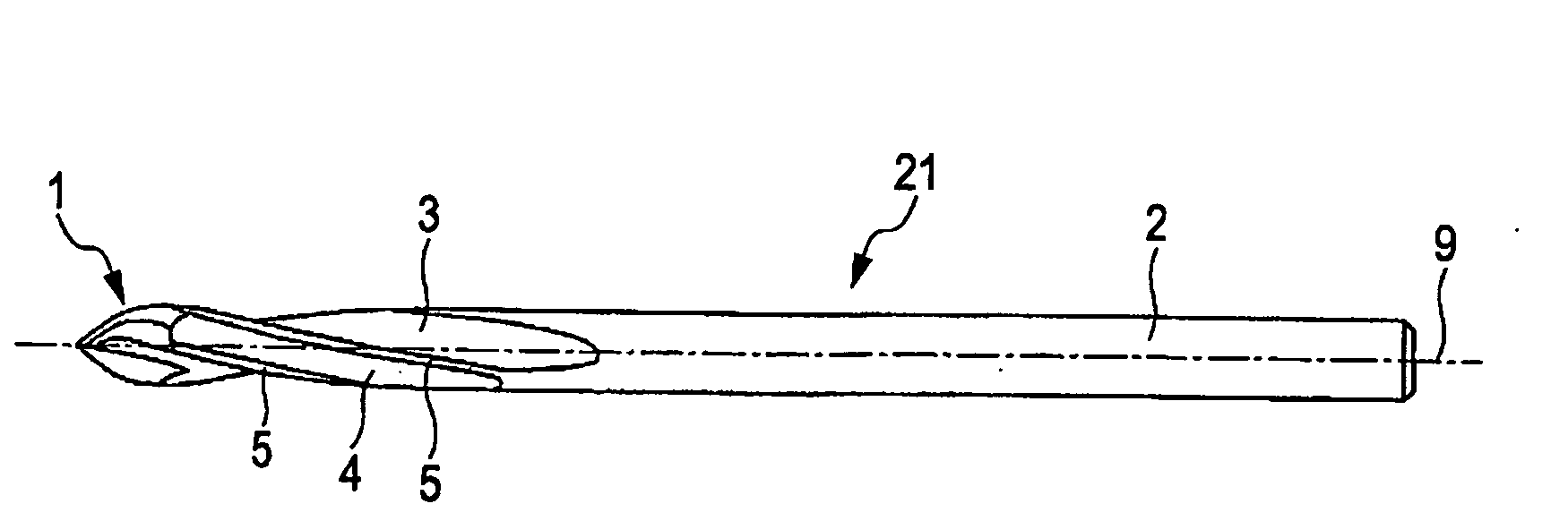

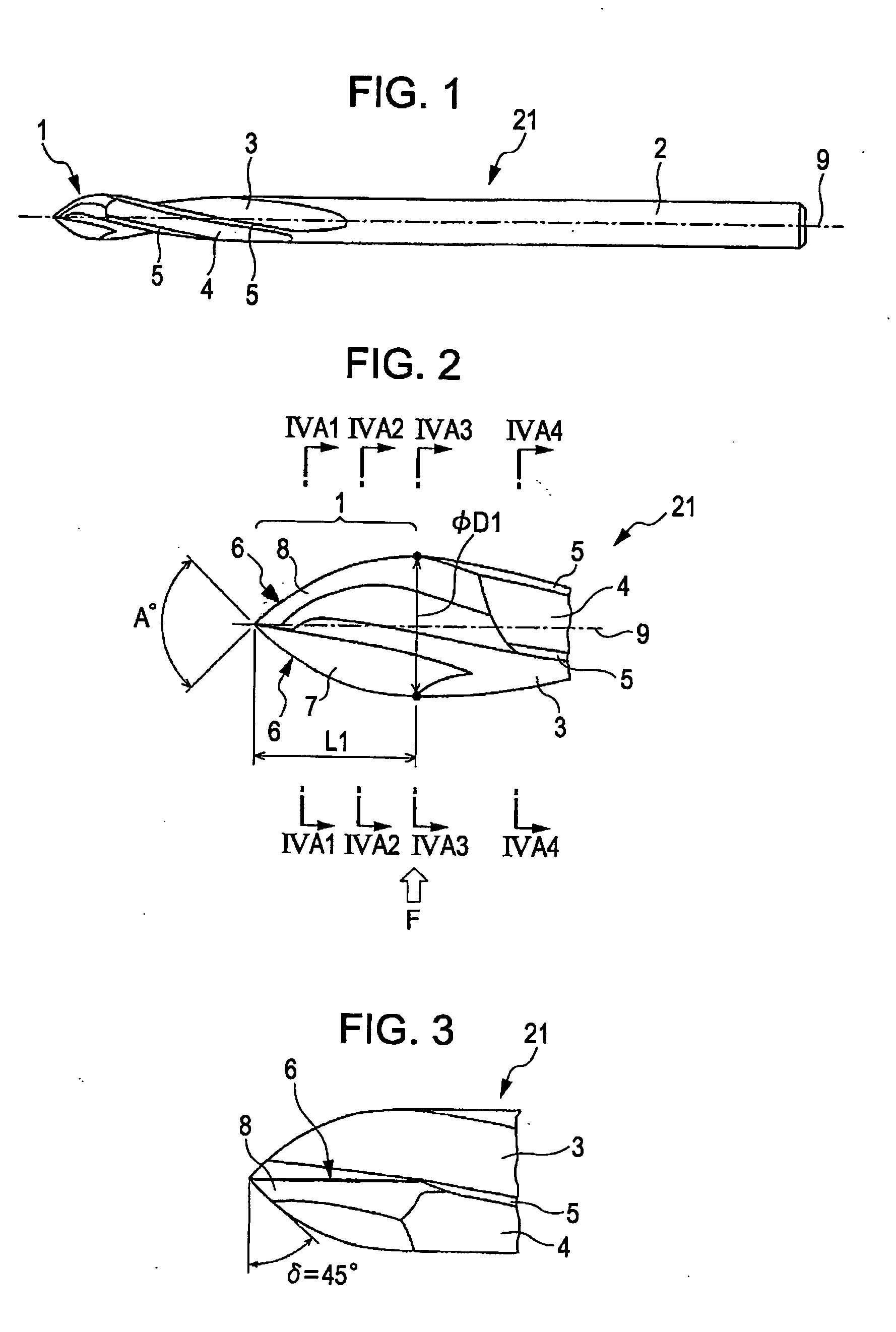

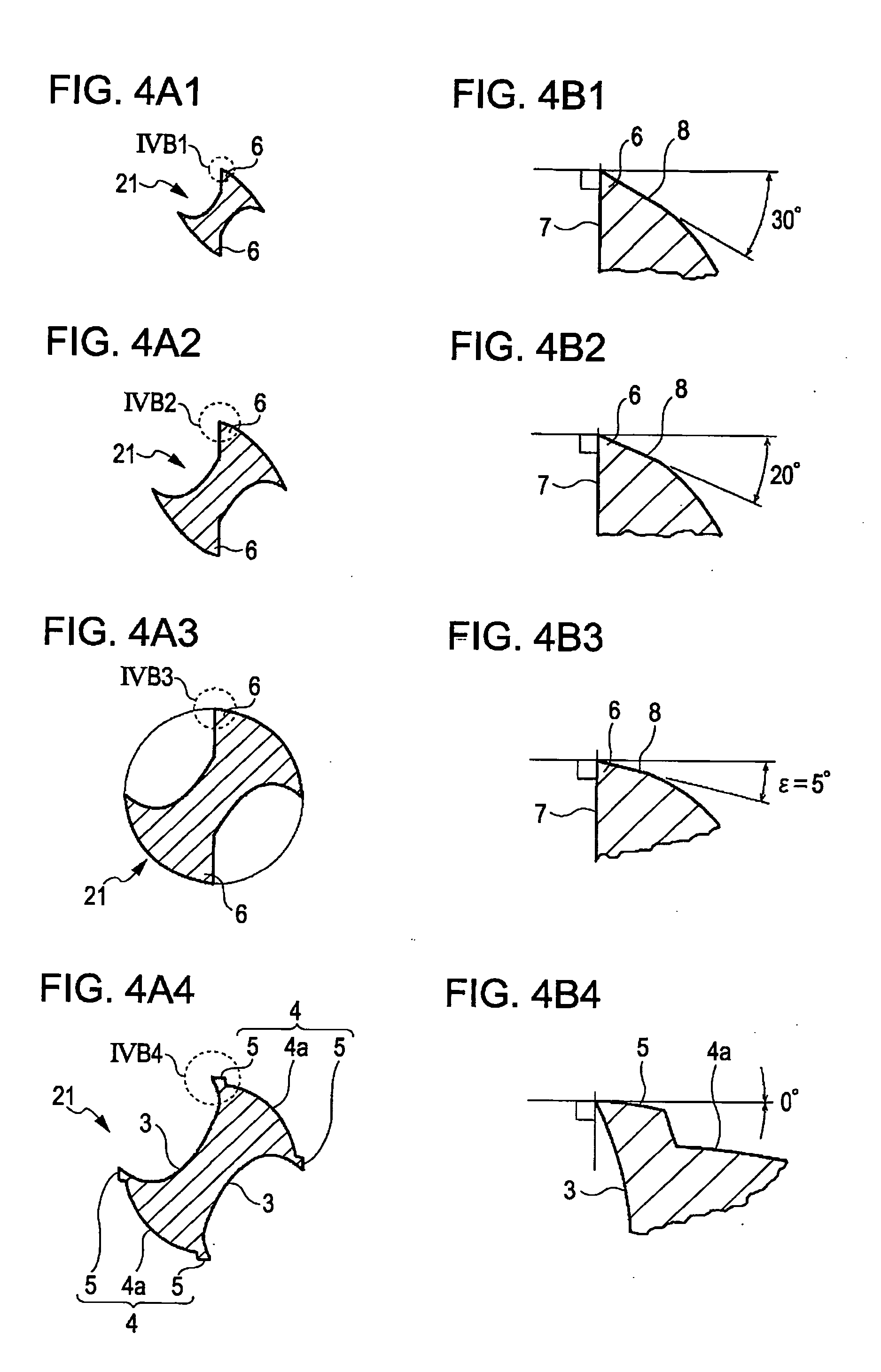

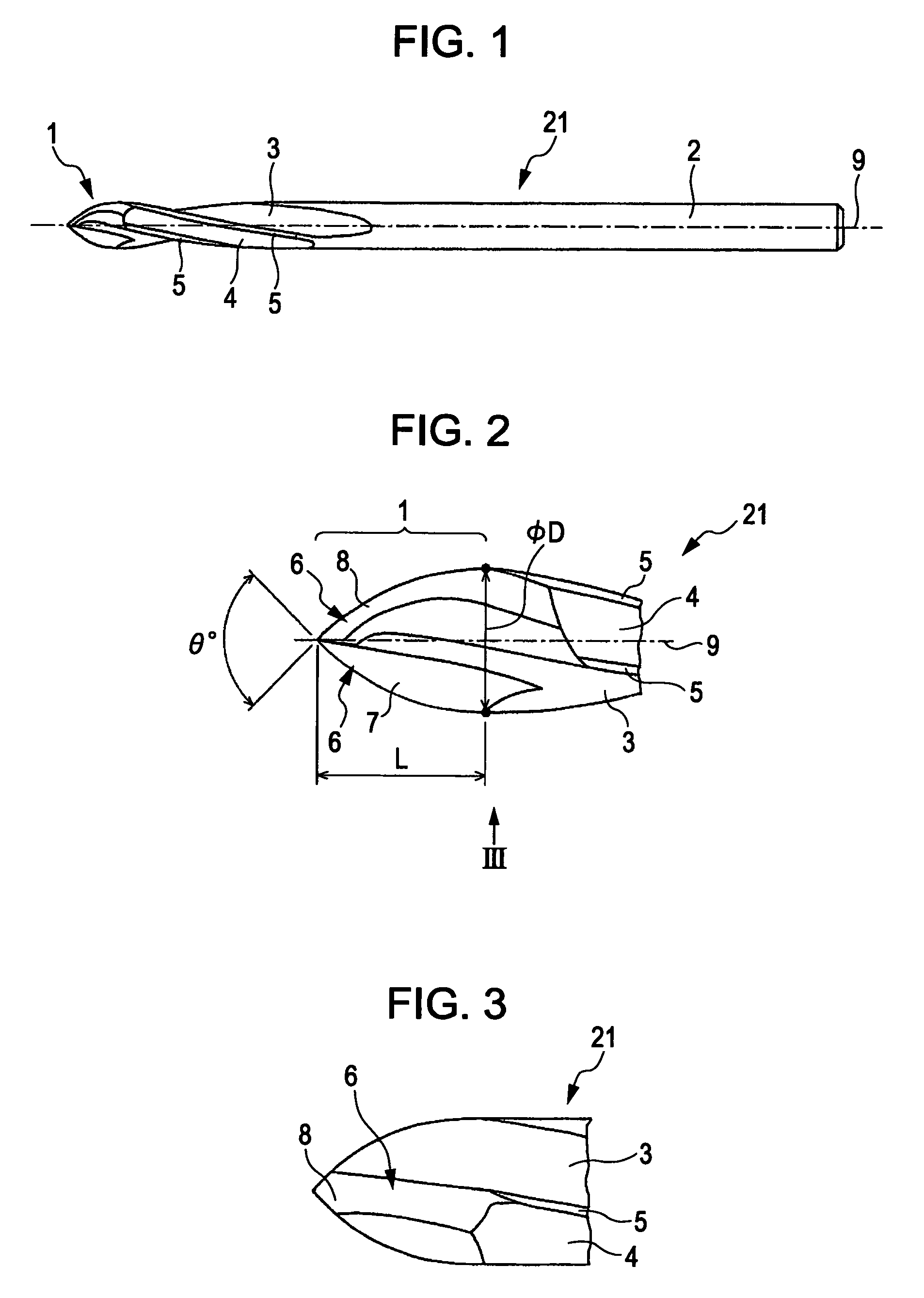

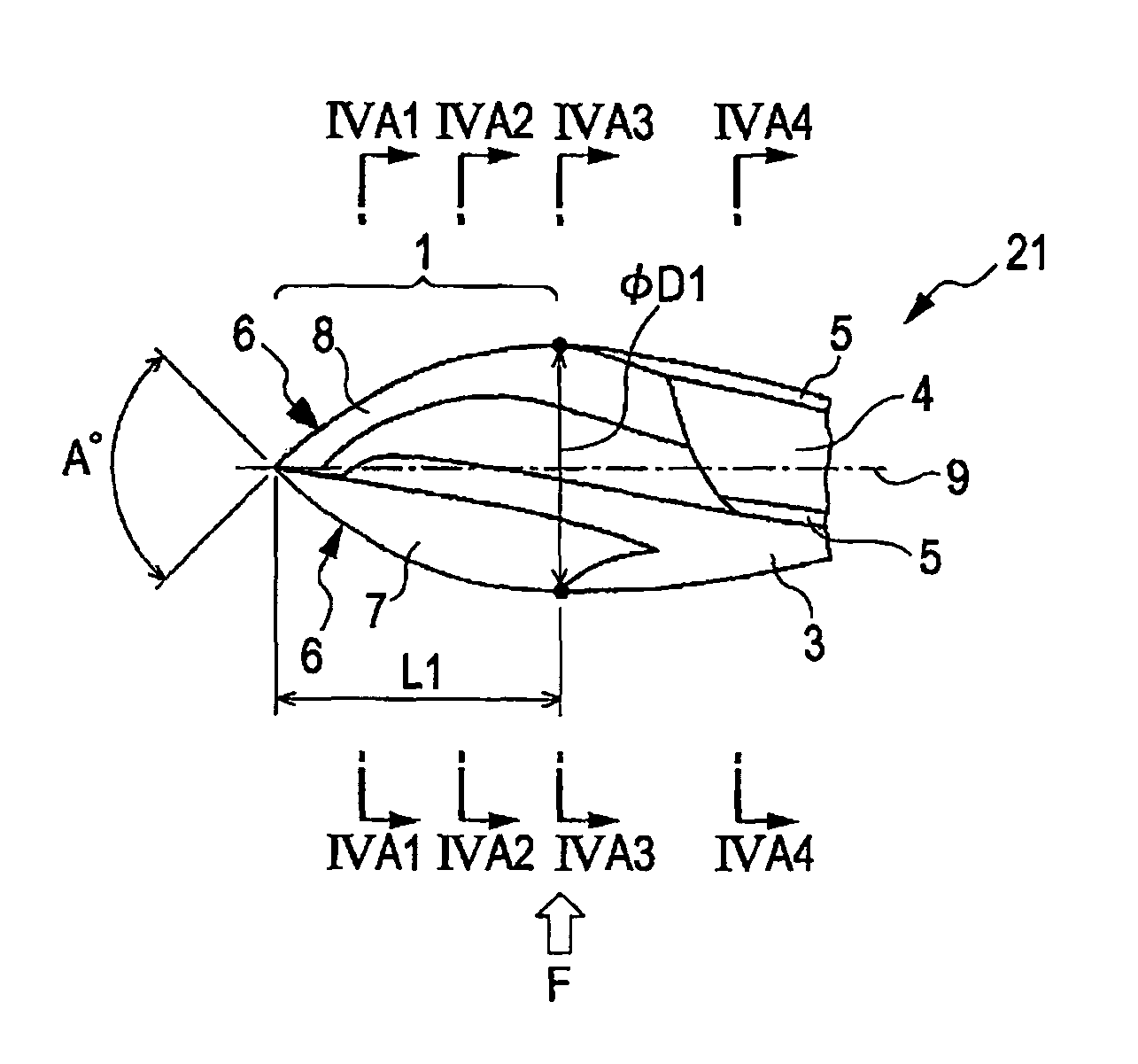

Drill and drilling method for workpiece

ActiveUS20100158626A1Improve wear resistanceImprove accuracyWood turning toolsTransportation and packagingMaximum diameterEngineering

A drill includes a cutting edge. The cutting edge has a point angle which is continuously decreased from a center-position point angle A (herein, 0°<A<180°) at a center position to a maximum-diameter-position point angle of 0° at a maximum diameter position. The cutting edge has a relief angle which is continuously decreased from the center position to the maximum diameter position. The cutting edge of the drill has a relief angle at the maximum diameter position. Hence, the cutting edge also serves as a cutting edge for reaming. The ridgeline and relief face of the cutting edge have no corner, thereby providing good wear resistance.

Owner:SUBARU CORP

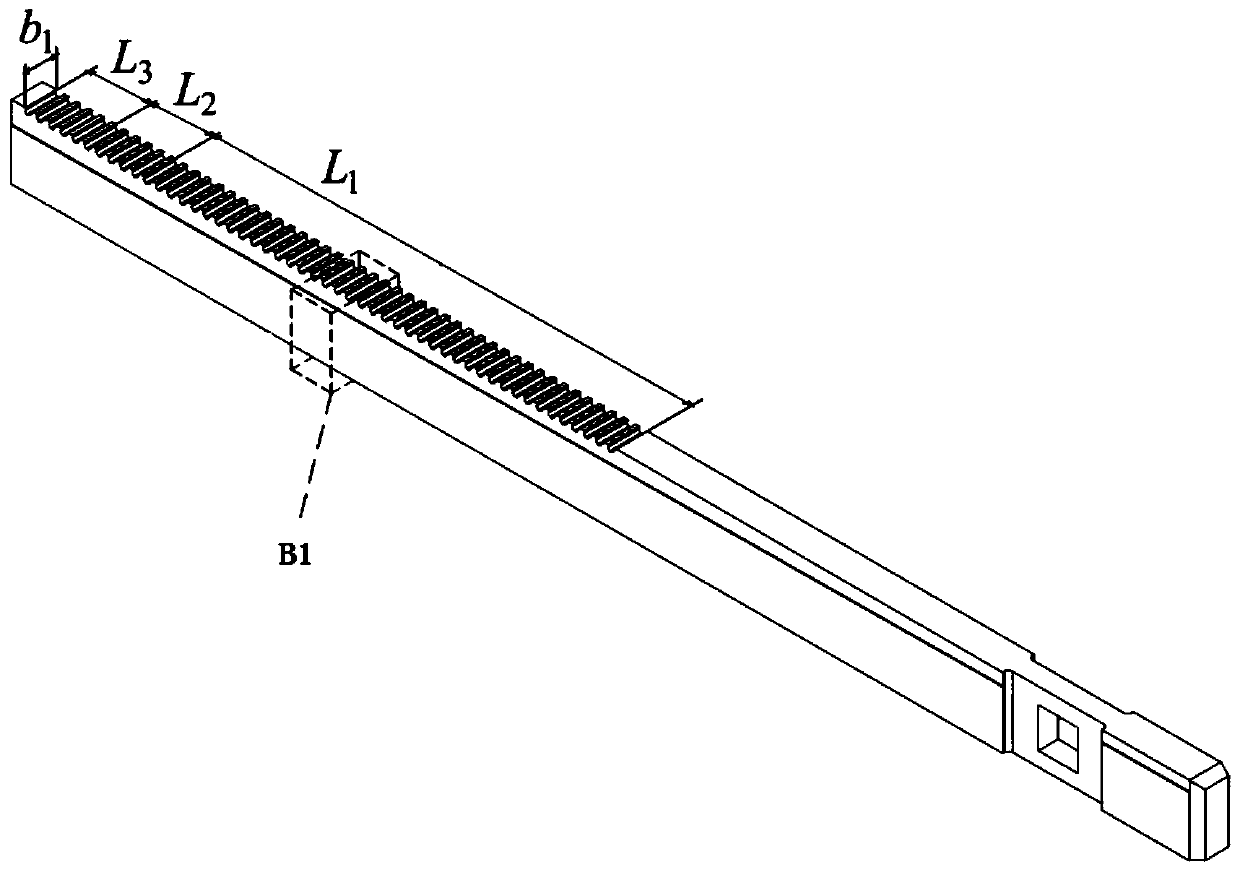

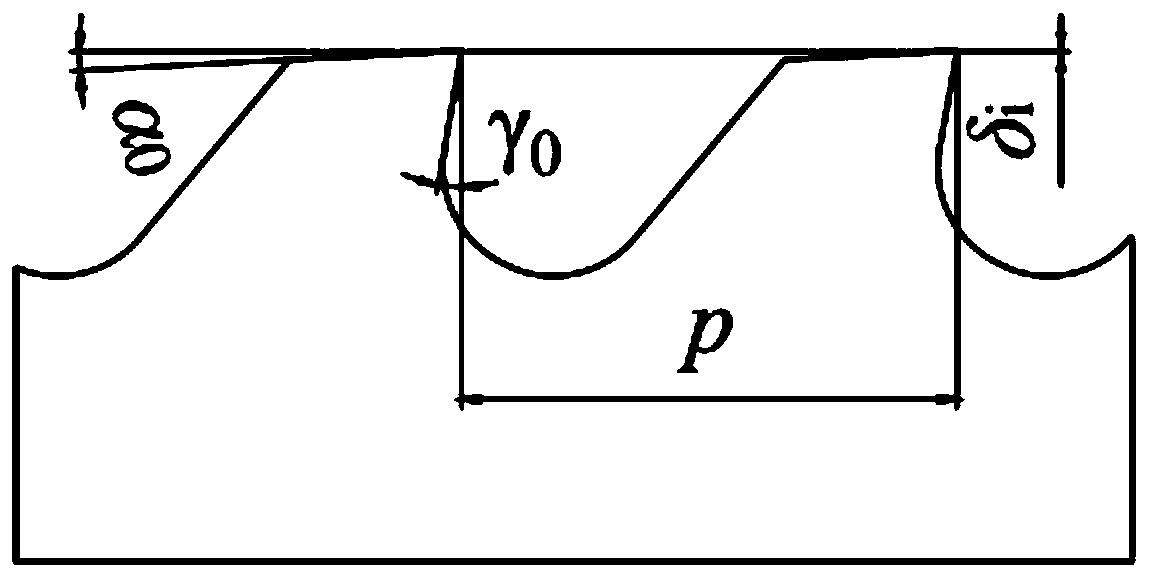

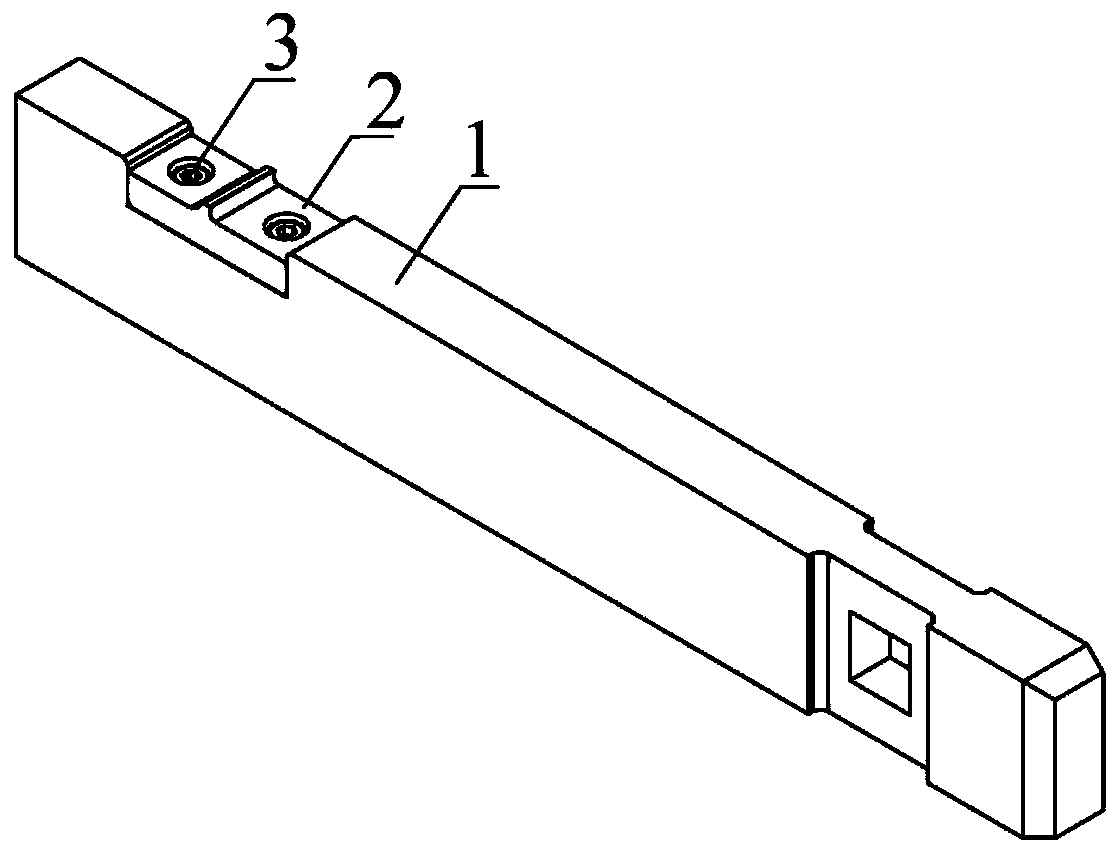

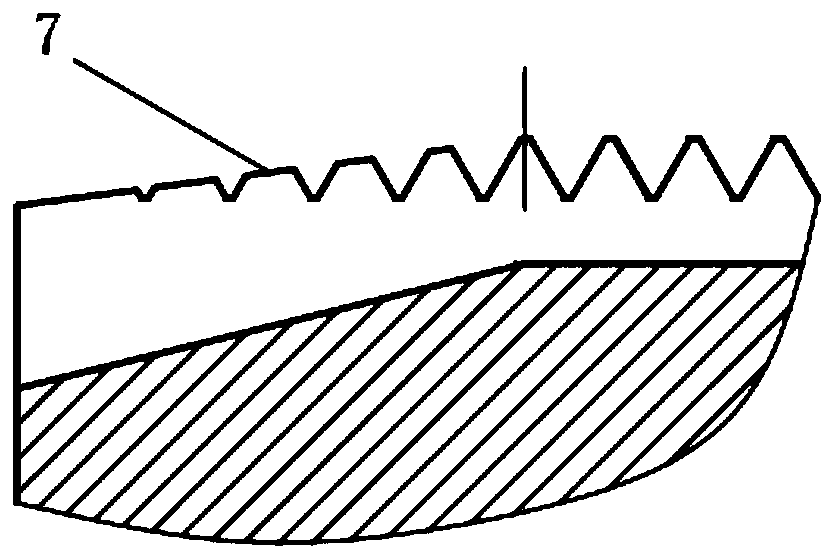

Broaching tool imitating shape of mantis mouthparts palate and preparation method of broaching tool imitating shape of mantis mouthparts palate

ActiveCN105904022AExcellent machinabilityImprove cutting performanceBroaching toolsArthropod mouthpartsEngineering

The invention discloses a broaching tool imitating the shape of a mantis mouthparts palate and a preparation method of the broaching tool imitating the shape of the mantis mouthparts palate. An existing broaching tool is large in workload, and abrasion of the tool is serious. Grooves are formed in the top faces of tool teeth of the broaching tool; the rise per tooth of a tool tooth part of a tool head is in arithmetic progression distribution; in the direction from a tooth crest to a tooth groove, the gradient change of the area of the cross section of the tool teeth of the tool head and the gradient change of the area of the cross section of the mantis palate are consistent; and the compactness and the hardness of the surfaces of the tool teeth of the tool head are both larger than those of the interior. The preparation method of the broaching tool includes the steps that a mantis palate three-dimensional curved surface model is constructed, the area gradient of the mantis palate is acquired, the area gradient of the tool teeth of the tool head in the direction from the tooth crest to the tooth groove is determined, and the outline of the tool teeth is designed according to the area gradient of the toot teeth; the multiple grooves are machined in the top face of each tool tooth; on the same longitudinal cross section of the tool head, the positions of the grooves in each tool tooth correspond to the top faces of the portions, not provided with grooves, of the tool teeth; and heat treatment of the tool head is performed. The cutting performance of the broaching tool is optimized, the cutting load is reduced, and the service life of the broaching tool is prolonged.

Owner:HANGZHOU DIANZI UNIV

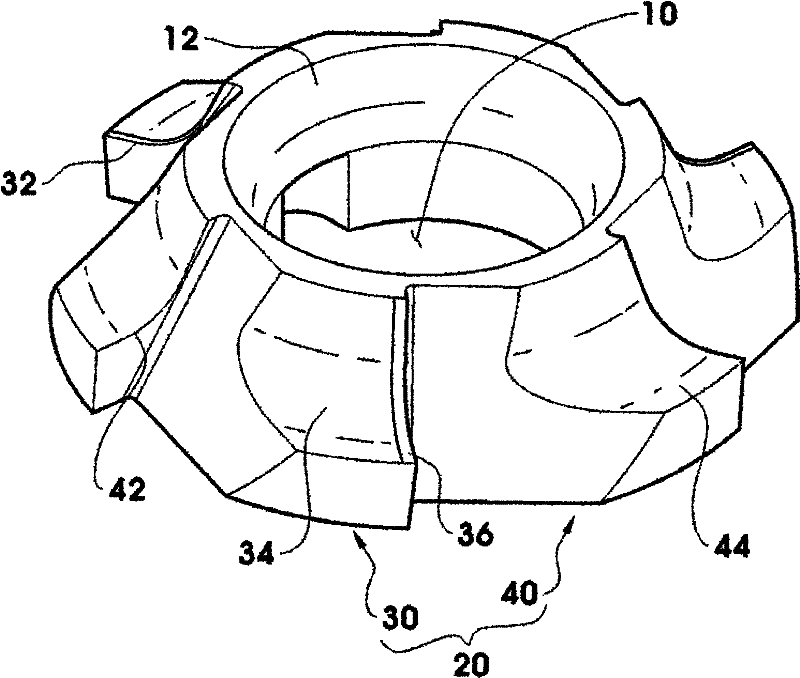

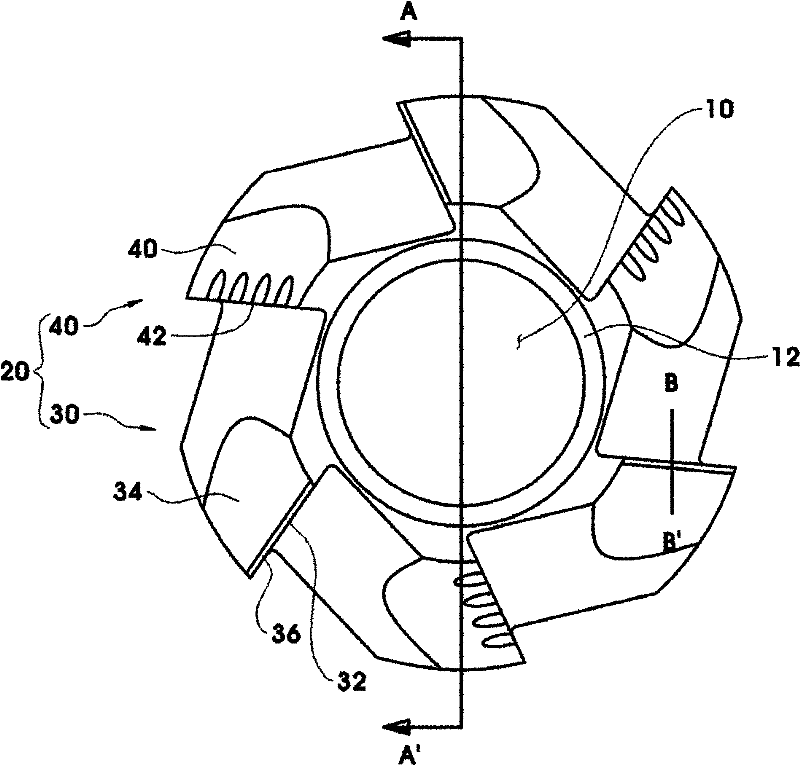

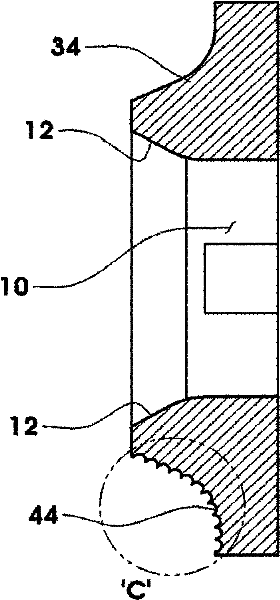

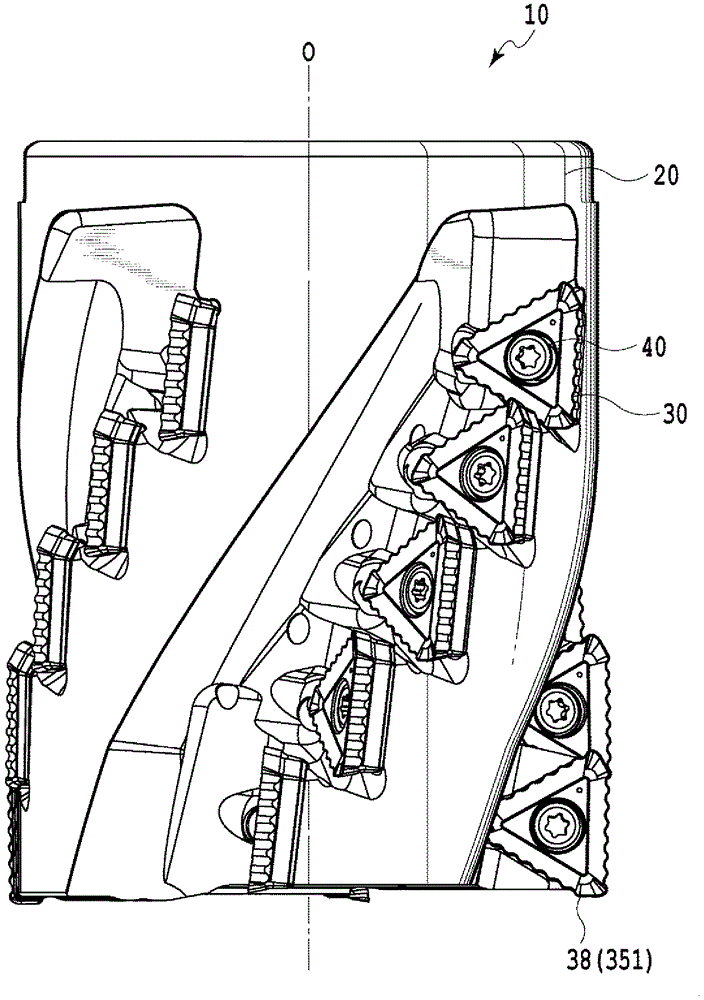

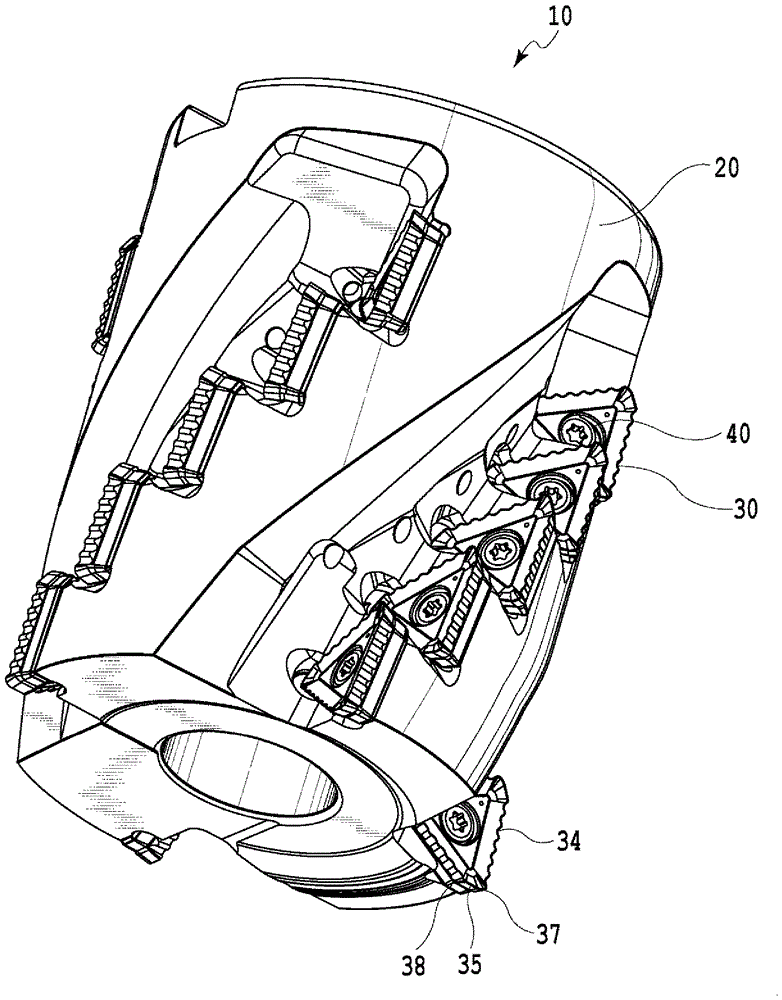

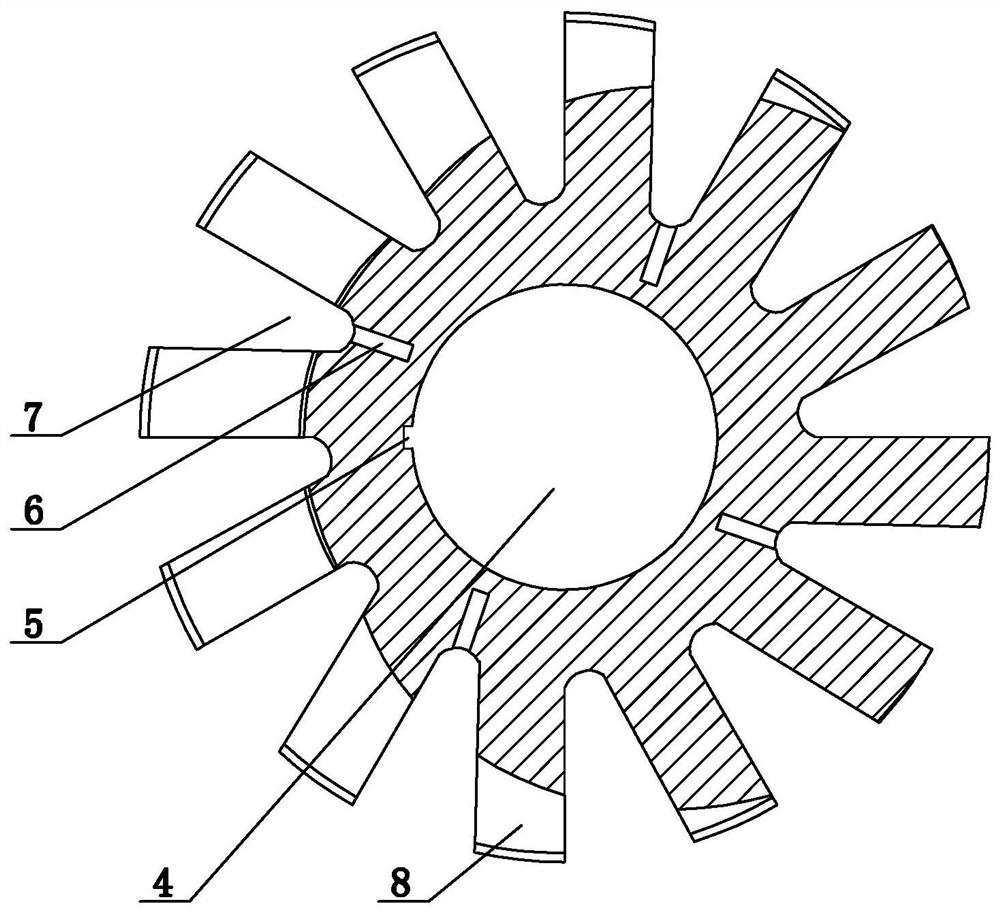

Cutter for chamfering

InactiveCN102131605AImprove processing powerReduce cutting loadMilling cuttersMilling equipment detailsSwarfSmooth surface

The present invention aims to provide a cutter for chamfering that improves the ability to deal with the chips created during the chamfering work and thus reduces cutting load. To achieve the above objective, an aspect of the present invention provides a cutter for chamfering, which may be connected to a rotating shaft so as to rotate and trim an edge of an object. The cutter may have a through-hole (10) formed in its center, so that a fastening bolt inserted through the through-hole (10) may connect the cutter to one end of the rotating shaft; the cutter may be shaped as a cogwheel having a multiple number of cutting blades (20) that are positioned radially about the through-hole (10) and formed as an integrated body; the cutting blades (20) may be shaped to generally protrude towards the center, with each of the blades including a blade portion (32, 42), which is formed in an end part of the cutting blade (20) in a direction of rotation, and an arc (34, 44) portion, which forms a concave arced surface; and the cutting blades (20) may include finish-grinding blades (30) and rough- grinding blades (40) that are positioned alternately, the finish-grinding blades (30) having smooth surfaces on the arc portions (34), and the rough-grinding blades (40) having rough surfaces on the arc portions (44). According to the present invention, the ability of the chamfering cutter to handlechips can be improved, and the cutting load can be lowered, so that the chamfering work can be facilitated, the work speed can be increased, and the durability of the chamfering cutter can be prolonged.

Owner:金 容范

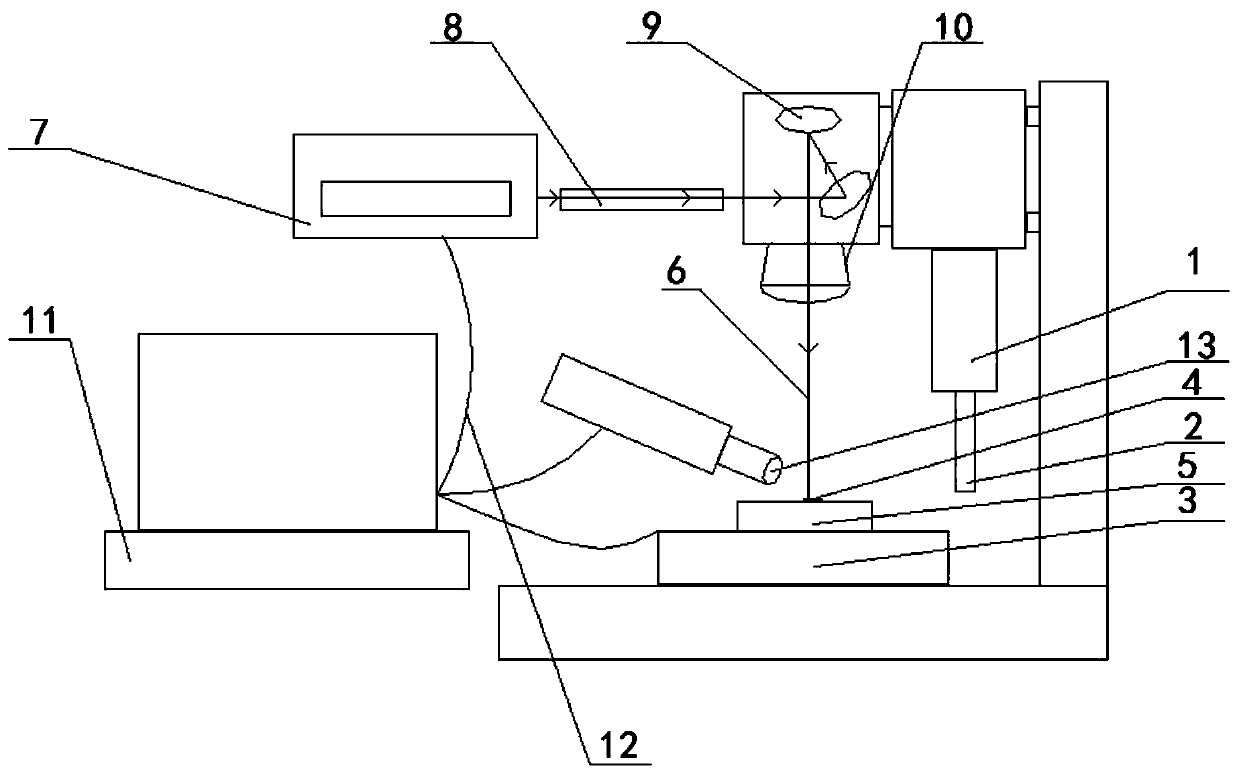

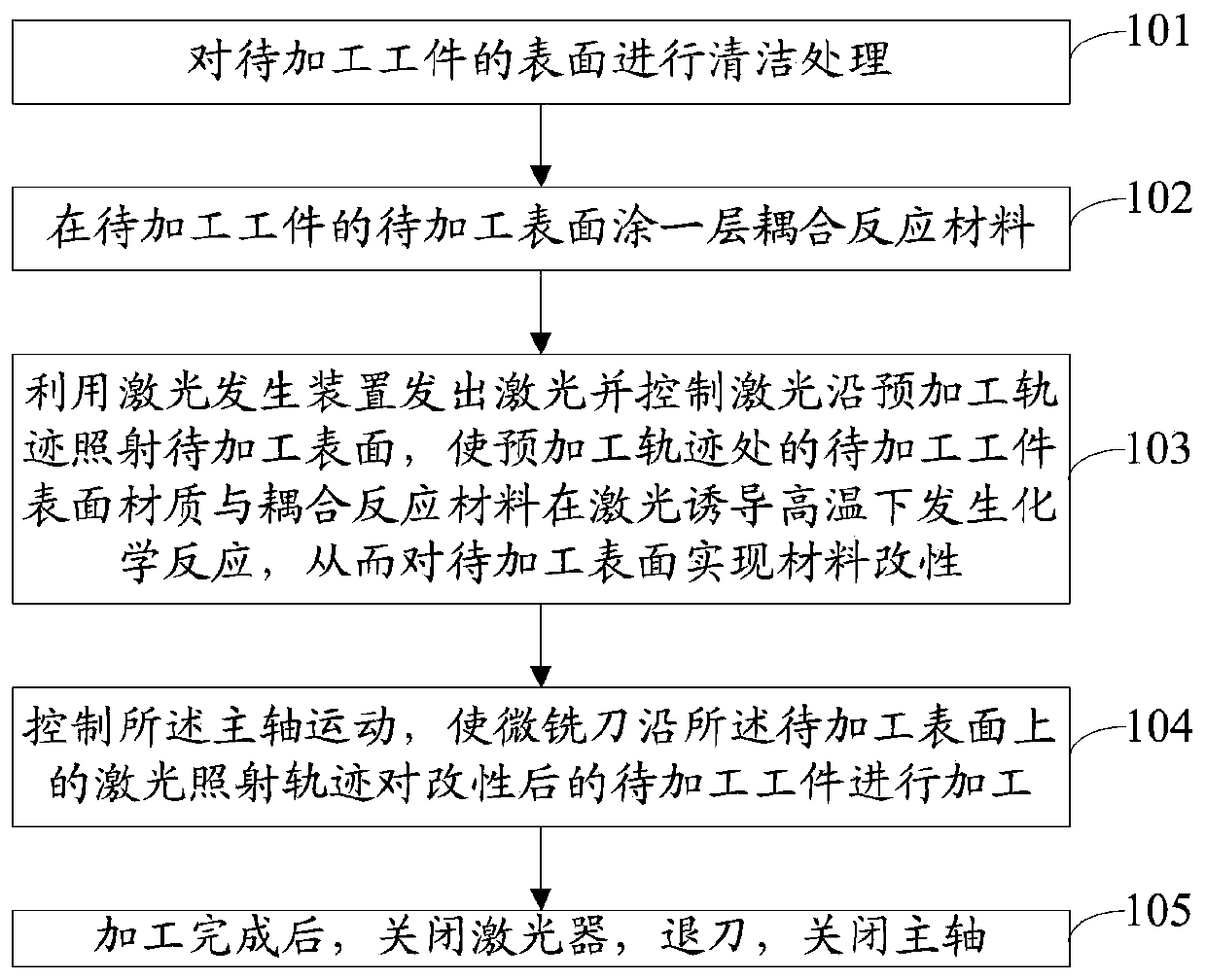

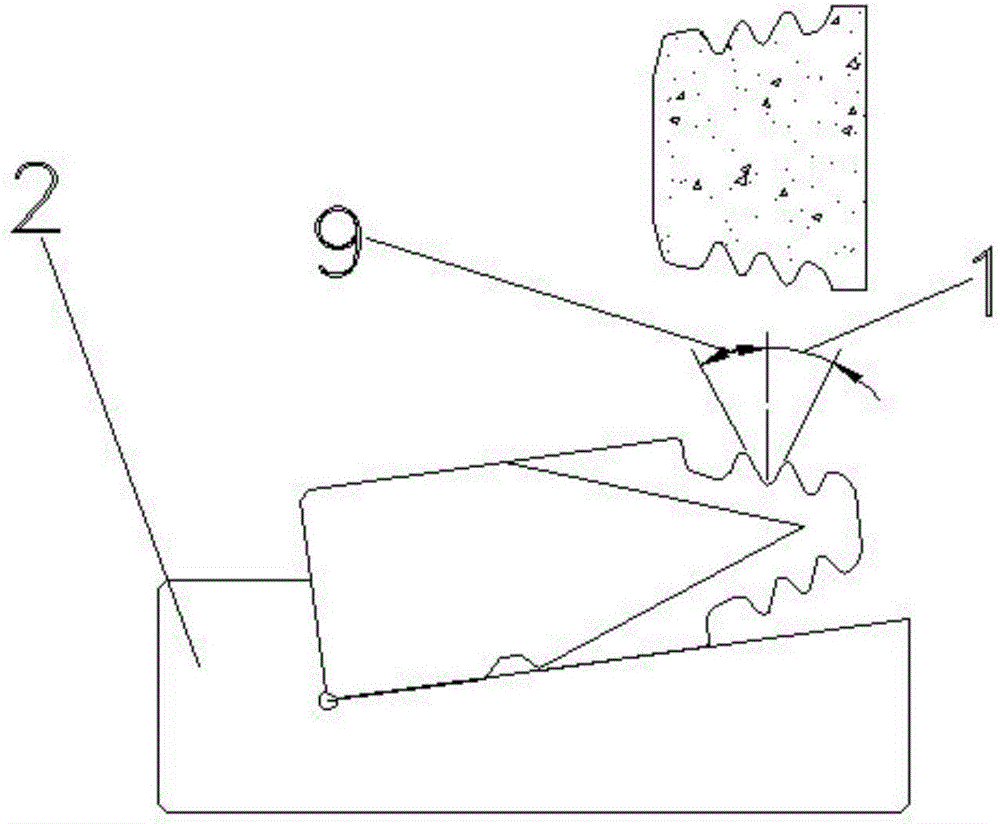

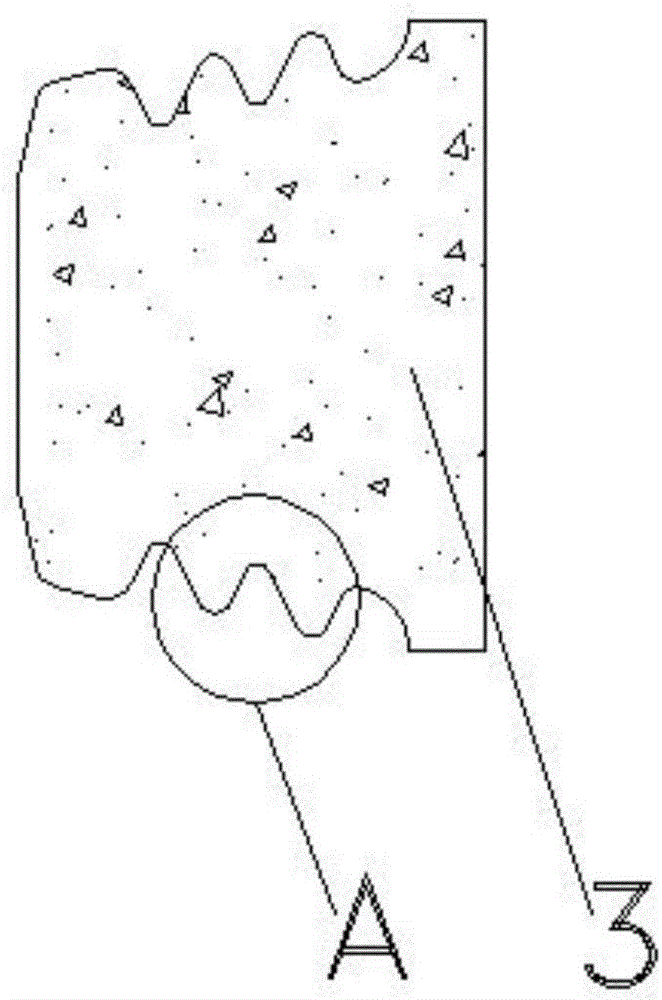

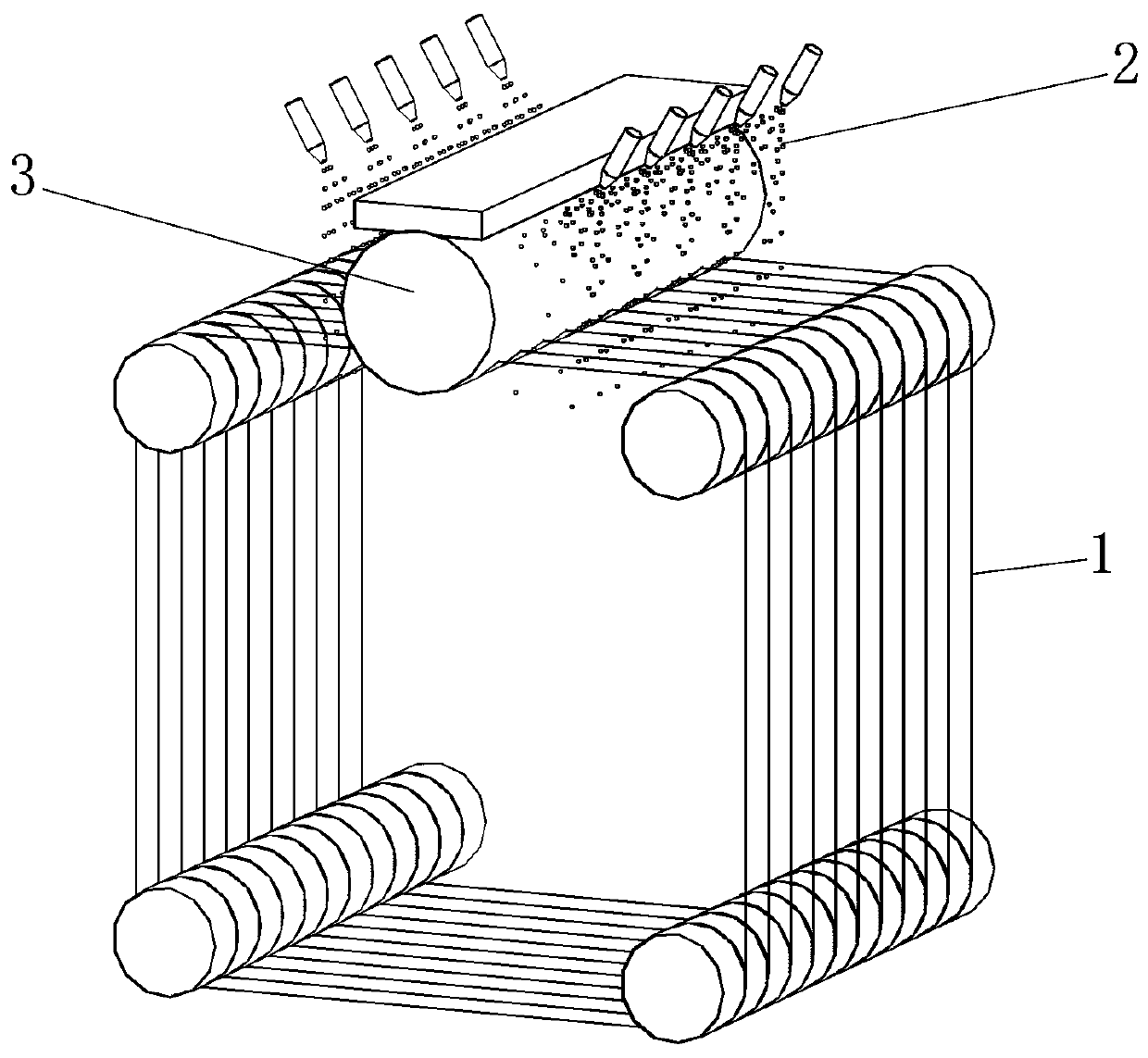

Machining device and method under laser-induced material coupling reaction

ActiveCN110625401AChanging Micromilling Removal MechanismReduce hardnessOther manufacturing equipments/toolsLaser beam welding apparatusChemical reactionThree dimensional microstructure

The invention discloses a machining device and method under a laser-induced material coupling reaction. The machining device comprises a laser generation device and a milling machine machining device;the milling machine machining device comprises a spindle, a micro-milling cutter and a working table; the laser generation device, the spindle and the micro-milling cutter are all located on the upper part of the working table; the micro-milling cutter is fixed to the spindle; the laser generation device and the micro-milling cutter both directly face the working table; the working table is usedfor storing or fixing to-be-machined workpieces with to-be-machined surfaces coated with coupling reaction materials; the laser generation device is used for generating a laser with the power being less than 6W and irradiating the laser to the to-be-machined surfaces; the micro-milling cutter is used for machining the to-be-machined workpieces along the laser trajectory of the to-be-machined surfaces; and the coupling reaction materials are materials chemically reacting with the to-be-machined workpieces during laser heating. According to the machining device and method, the workpiece machining efficiency, surface quality and three-dimensional microstructure causativity performance can be improved, and the service life of the micro-milling cutter is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

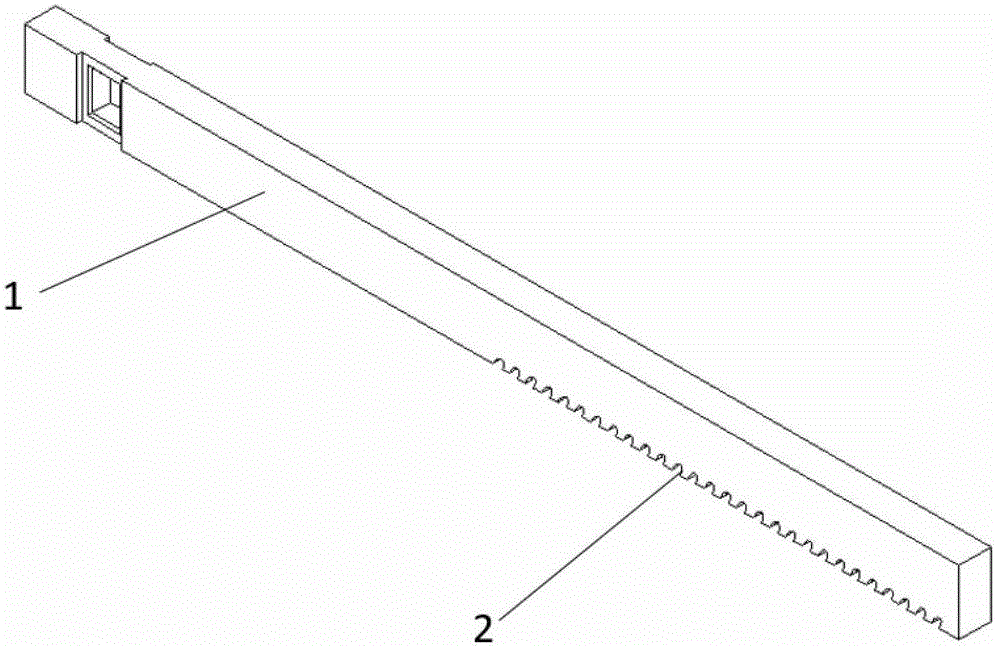

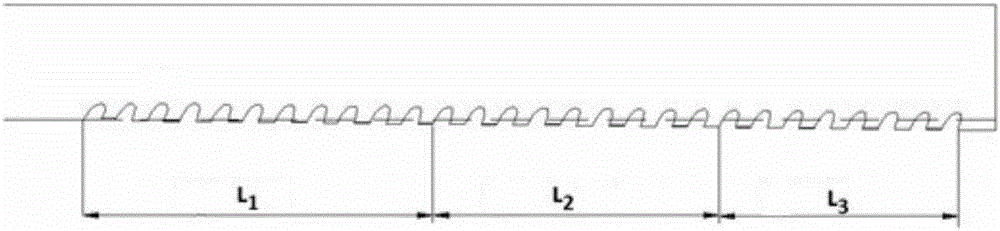

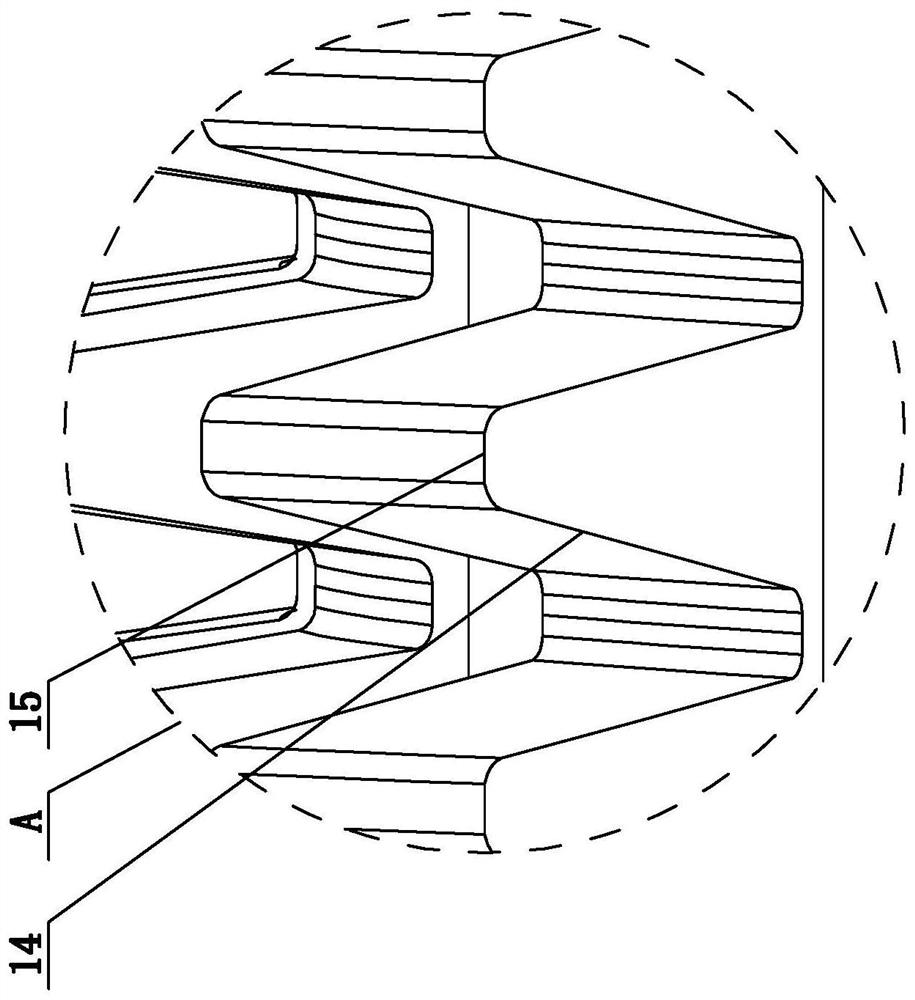

Grinding technology and device for wheel groove finishing broach with equal cutting angles

The invention relates to a grinding technology and device for a wheel groove finishing broach with equal cutting angles. The technology includes the following steps that the circumstance that the tooth profile angle of a fir-shaped tooth profile work face of the wheel groove broach is equal to the tooth profile angle of a non-work face serves as the benchmark, a sine magnetic force table is adjusted to reach the rated angle, and then the wheel groove broach is fixed to the sine magnetic force table; the tooth profile of the wheel groove broach is subjected to rough grinding, semi-finish grinding and finish grinding; a tooth profile rear angle relief grinding abrasion wheel is used for conducting relief grinding on the tooth profile rear angle of the fir-shaped tooth profile work face of the wheel groove broach and the tooth profile rear angle of the non-work face, so that the tooth profile rear angle of the fir-shaped tooth profile work face of the wheel groove broach is equal to the tooth profile rear angle of the non-work face; and a wheel cut tooth profile relief grinding abrasion wheel is used for conducting integral precise relief grinding on the wheel cut tooth profile on the fir-shaped tooth profile of the wheel groove broach. The grinding technology and device have the beneficial effects that the broaching allowance of the tooth profile work face and the broaching allowance of the non-work face are consistent, the ground broach work face and the ground broach non-work face are symmetrically stressed, the service life is long, the cutting precision is high, chip cutting and rolling are convenient, and the cutting loads are small.

Owner:EST TOOLS

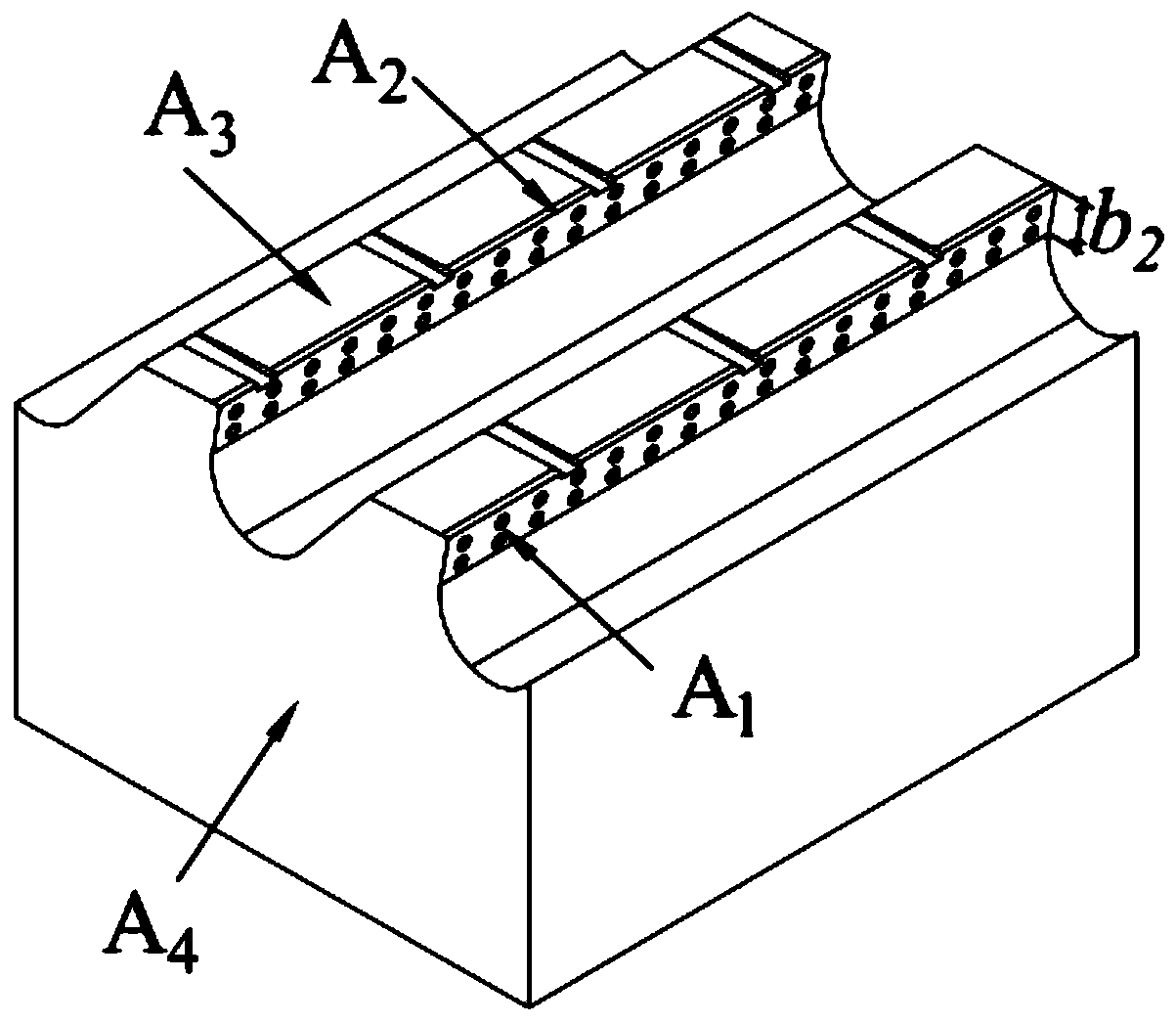

Microstructure keyway broach for surfaces of bionic dung beetle elytra, and preparation method thereof

The invention discloses a microstructure keyway broach for the surfaces of bionic dung beetle elytra, and a preparation method thereof. Serious extrusion, friction and wear exist in rake faces and chips in a broaching process of an existing broach. According to the microstructure keyway broach for the surfaces of the bionic dung beetle elytra, and the preparation method thereof, microstructures onthe surfaces of the dung beetle elytra are obtained through scanning, then a single-point diamond tool is produced, and m rows*n columns of bionic microstructures are formed on the rake face of eachbroach tooth in a rough broaching area and a semi-finish broaching area of the broach separately, each bionic microstructure is composed of a central inverted-cone-frustum concave pit and a pluralityof boundary inverted-cone-frustum concave pits which are uniformly distributed in the circumferential direction of the central inverted-cone-frustum concave pit, and the sidewalls of all the boundaryinverted-cone-frustum concave pits communicate with the sidewall of the central inverted-cone-frustum concave pit; and the centers of the top surfaces of all the boundary inverted-cone-frustum concavepits are located in the circumference where the edge of the top surface of the central inverted-cone-frustum concave pit is located. According to the microstructure keyway broach for the surfaces ofthe bionic dung beetle elytra, and the preparation method thereof, the bionic microstructures are formed on the rake faces of the broach, so that the cutting performance of the broach can be optimized, the cutting load is reduced, and the purposes of protecting the broach, reducing the wear of the broach, and prolonging the service life of the broach are achieved.

Owner:HANGZHOU DIANZI UNIV

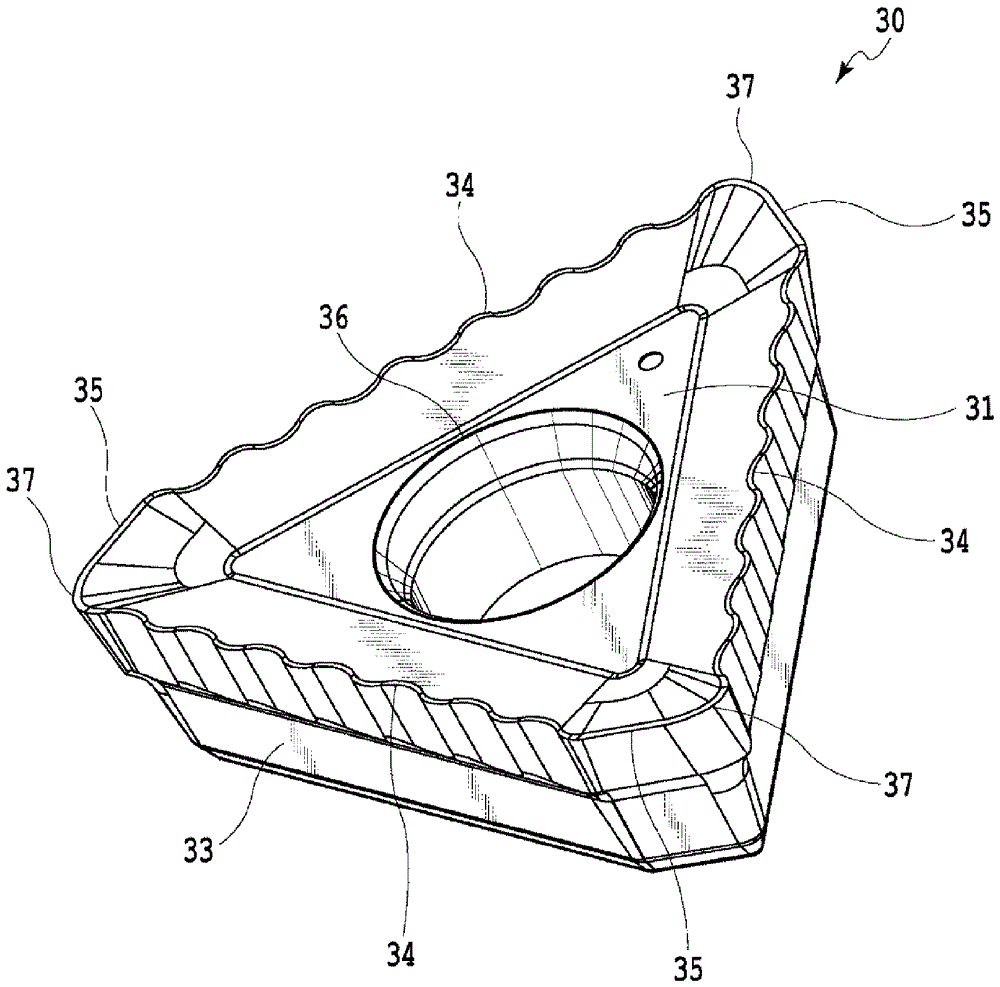

Replaceable edge-type rotating cutting tool

ActiveCN105813785ASuppression defectReduce cutting loadMilling cuttersMilling cutting insertsEdge typeWave form

Multiple grooves (27) are formed and in each of said grooves, multiple insert seats (28) are formed and cutting inserts (30) are detachably disposed. The cutting inserts (30) have main cutting edges (34), corner cutting edges, and auxiliary cutting edges (35), and the main cutting edges (34) are formed with a wave form when viewed from the direction of the cutting face. The cutting inserts (30) are disposed so that in the rotation tracks formed by the main cutting edges (34) of the respective cutting inserts (30) when the roughing cutter (10) is rotated around the rotation center axis (O), the wave phases of the rotation tracks formed by adjacent cutting inserts (30) in a single groove (27) in the direction along the rotation center axis (O) coincide, and at least some of the cutting inserts (30) are disposed so that the rotation tracks formed by some of the cutting edge portions overlap each other in the rotation center axis (O) direction. As a result, even when said cutting edge portions are used as a main cutting edge portion and as an inner blade, cutting load is reduced and damage is limited.

Owner:TUNGALOY CORP

Milling cutter, ultrasonic electric spark milling equipment milling method

ActiveCN111390311AAvoid short circuitEfficient dischargeMachining electrodesMilling cuttersMilling cutterMachined surface

The invention discloses a milling cutter. The milling cutter comprises a cutter body, a cutter blade and a discharge electrode arranged on the cutter body, wherein the cutter body comprises a cutter bar and a cutterhead arranged at one end of the cutter bar, a first fixing part and a second fixing part are arranged in the peripheral direction of the cutterhead in a bulging manner at an interval, the cutter blade is arranged at the first fixing part, the discharge electrode is arranged at the second fixing part, the maximum distance D1 between a position of the cutter blade and a cutterhead rotating shaft is larger than the maximum distance D2 between a position of the discharge electrode and the cutterhead rotating shaft, and the maximum height H1 between the cutterhead and the end, away from the cutterhead, of the cutter blade is larger than the maximum height H2 between the cutterhead and the end, away from the cutterhead, of a position of the discharge electrode. The discharge electrode electrically breaks down a dielectric medium between the discharge electrode and a metal part to produce high temperature, characteristics of a to-be-processed surface change, the surface of themetal part is softened, a free-cutting denatured layer is produced, and finally, the denatured layer and a thin substrate are cut off by the cutter blade.

Owner:HUNAN UNIV OF SCI & TECH

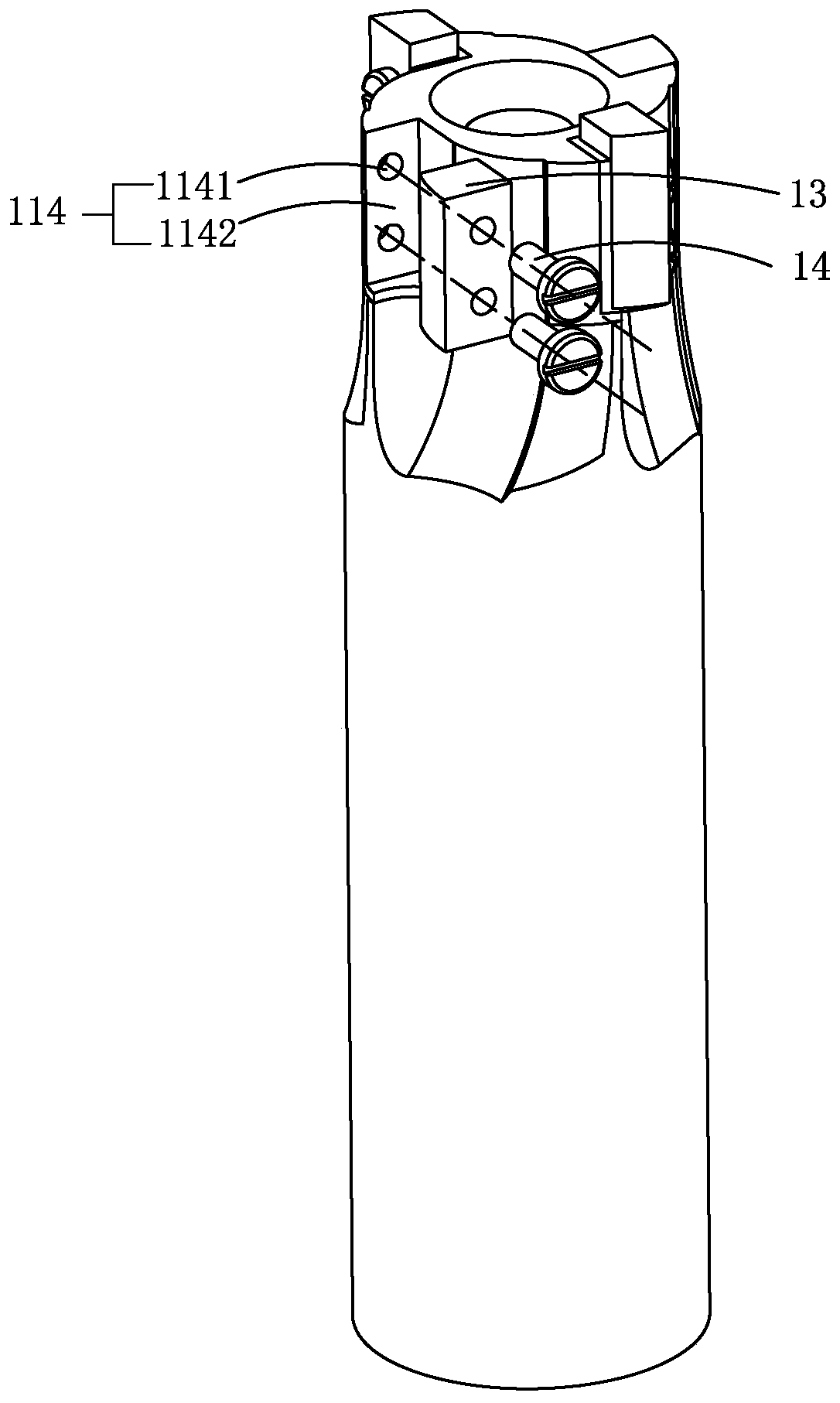

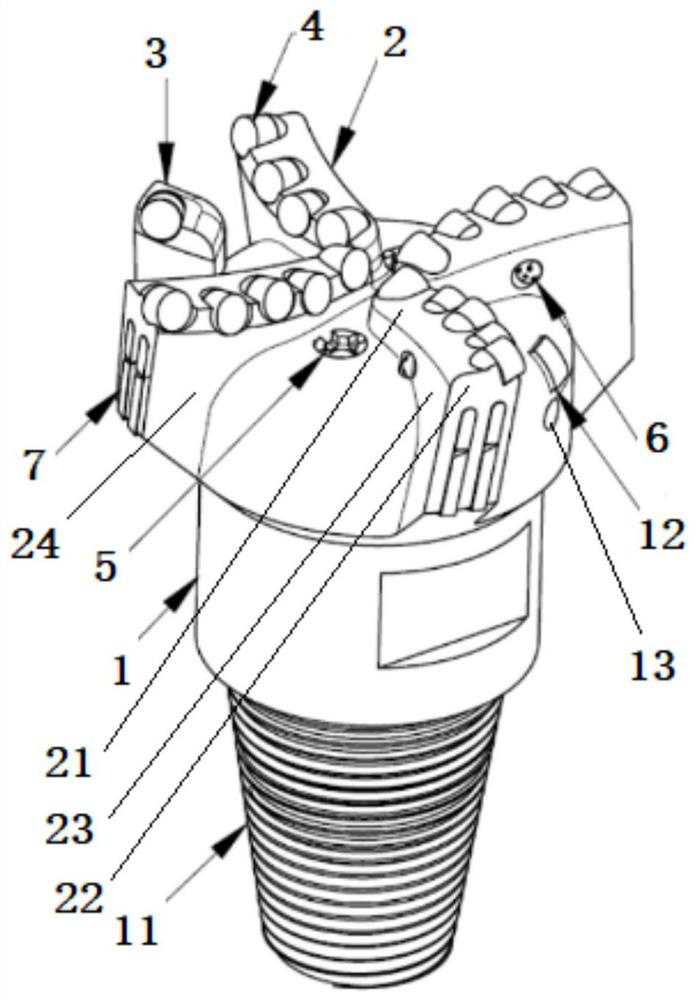

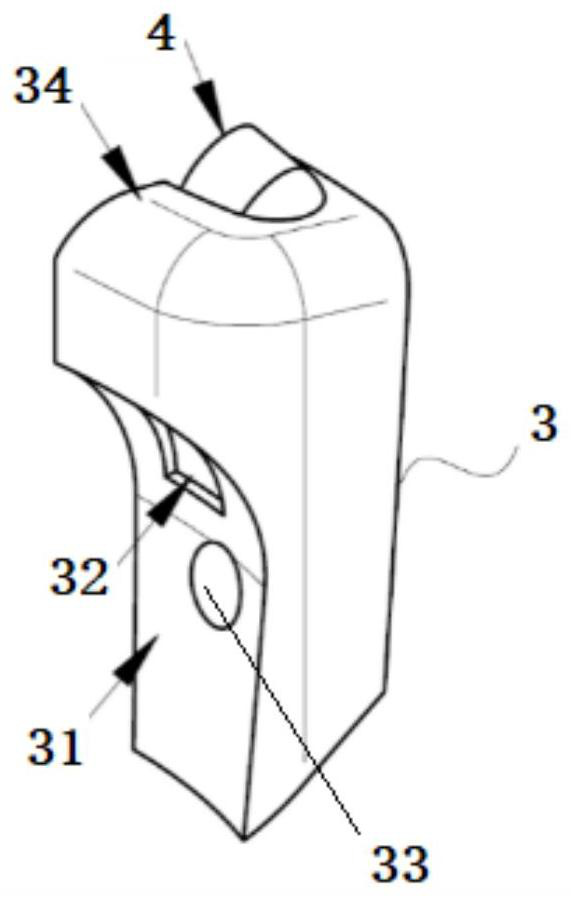

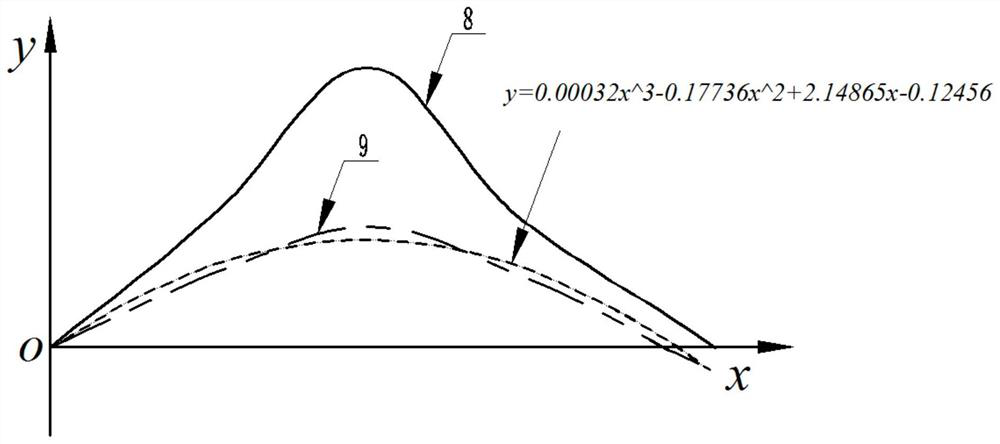

PDC drill bit for coal mine high-position directional drilling

ActiveCN111764831AStrong side cutting abilityWithout sacrificing build-up capabilityDrill bitsConstructionsMining engineeringStructural engineering

The invention discloses a PDC drill bit for coal mine high-position directional drilling. The PDC drill bit comprises a drill bit body, a plurality of fixed cutter wings, movable cutter wings and PDCcutting teeth, wherein the drill bit body and the fixed cutter wings are integrally formed, the movable cutter wings are detachably installed on the drill bit body, and the PDC cutting teeth are welded to the fixed cutter wings and the movable cutter wings. Fixed cutter wing tooth distribution faces extend to the edge of the front end of the drill bit body from the center close to the front end ofthe drill bit body in the radial direction, and gauge protection face connecting tooth distribution faces extend to the side face of the front end of the drill bit body; intersecting lines of the tooth distribution faces and the second side surface are designed according to a corrected mole front paw toe outline fitting curve, and the PDC cutting teeth are distributed along the intersecting lines; the movable cutter wings are arranged between the adjacent fixed cutter wings, and each movable cutter wing comprises a movable cutter wing tooth distribution face on which PDC cutting teeth can bemounted; the heights of the parts, higher than the front end of the drill bit body, of the fixed cutter wings and the movable cutter wings are consistent; and main runner nozzles are arranged on the drill bit body, and side blade nozzles are arranged on the fixed cutter wings. The directional deflecting capacity of a drill bit and the drilling adaptive capacity of the drill bit in a complex hard stratum can be improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

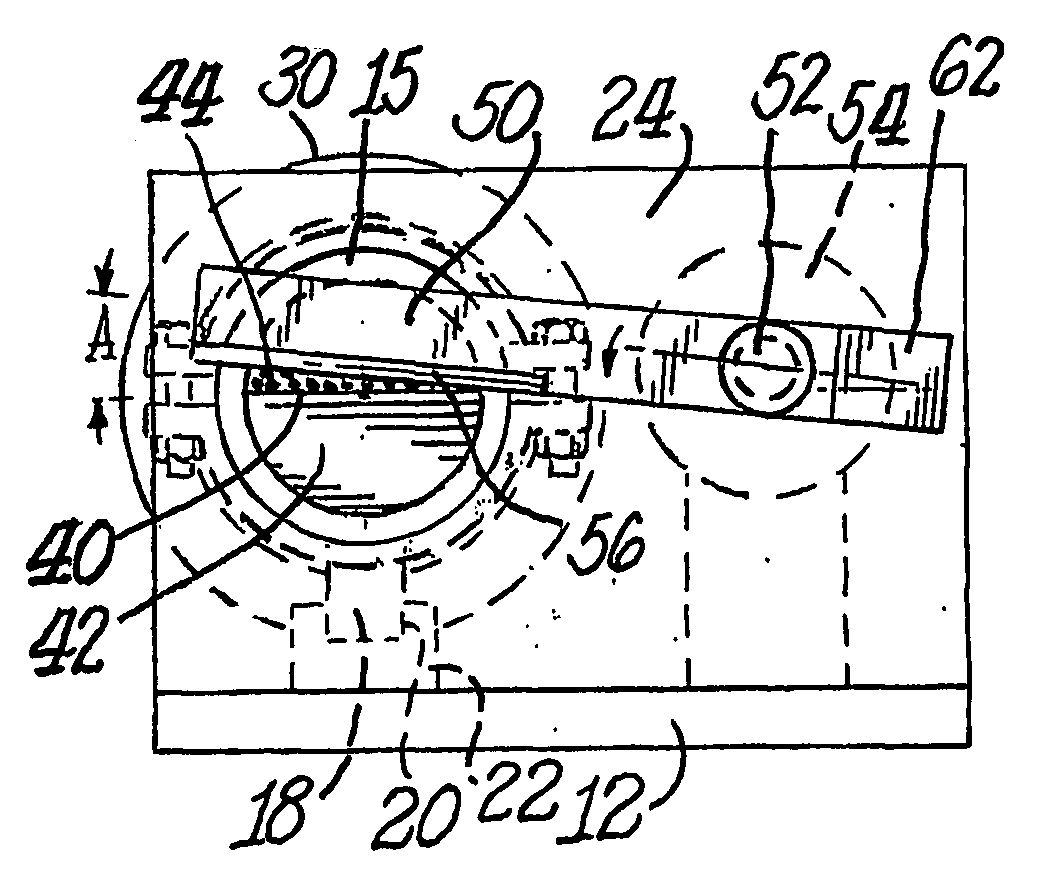

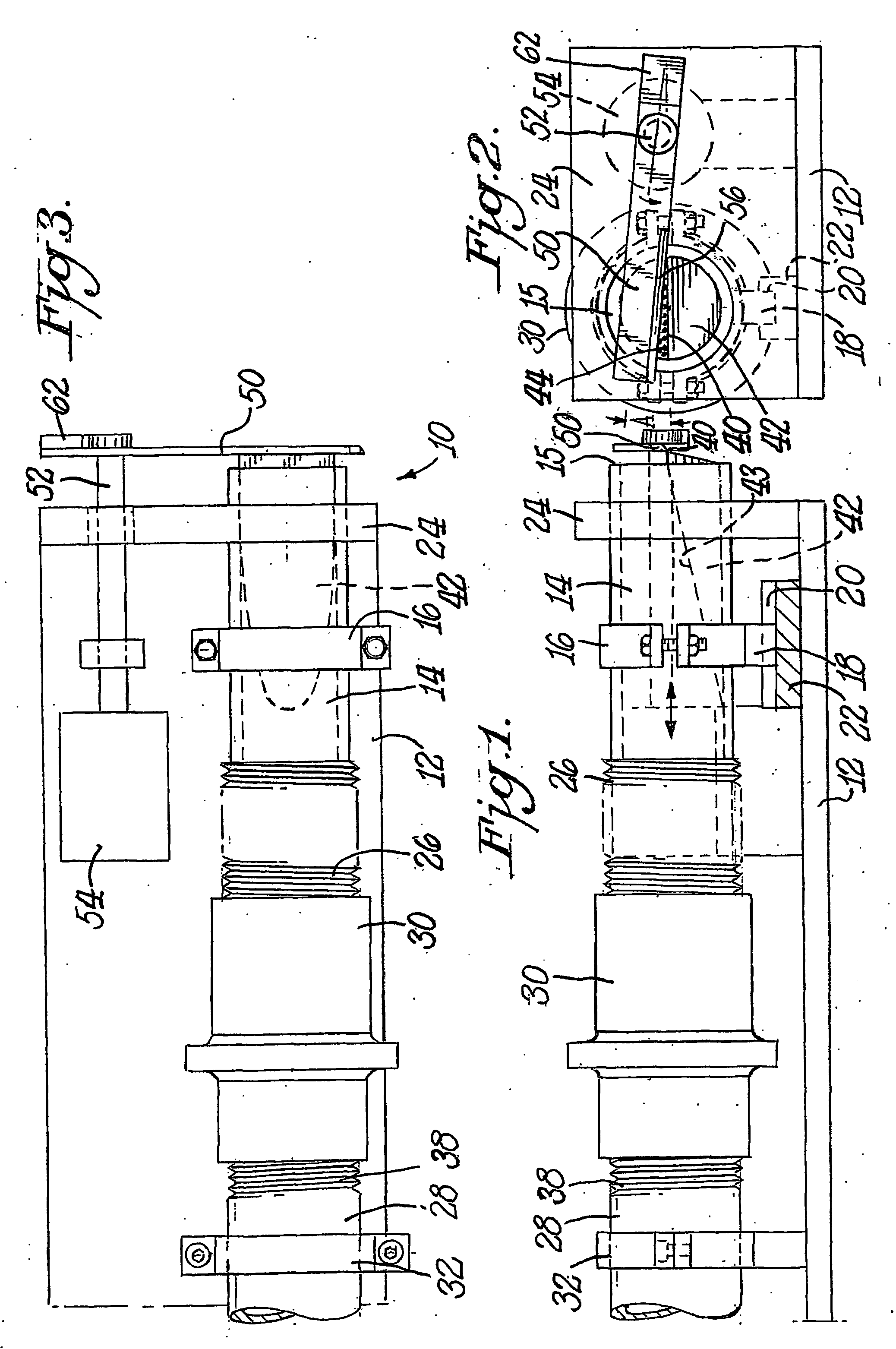

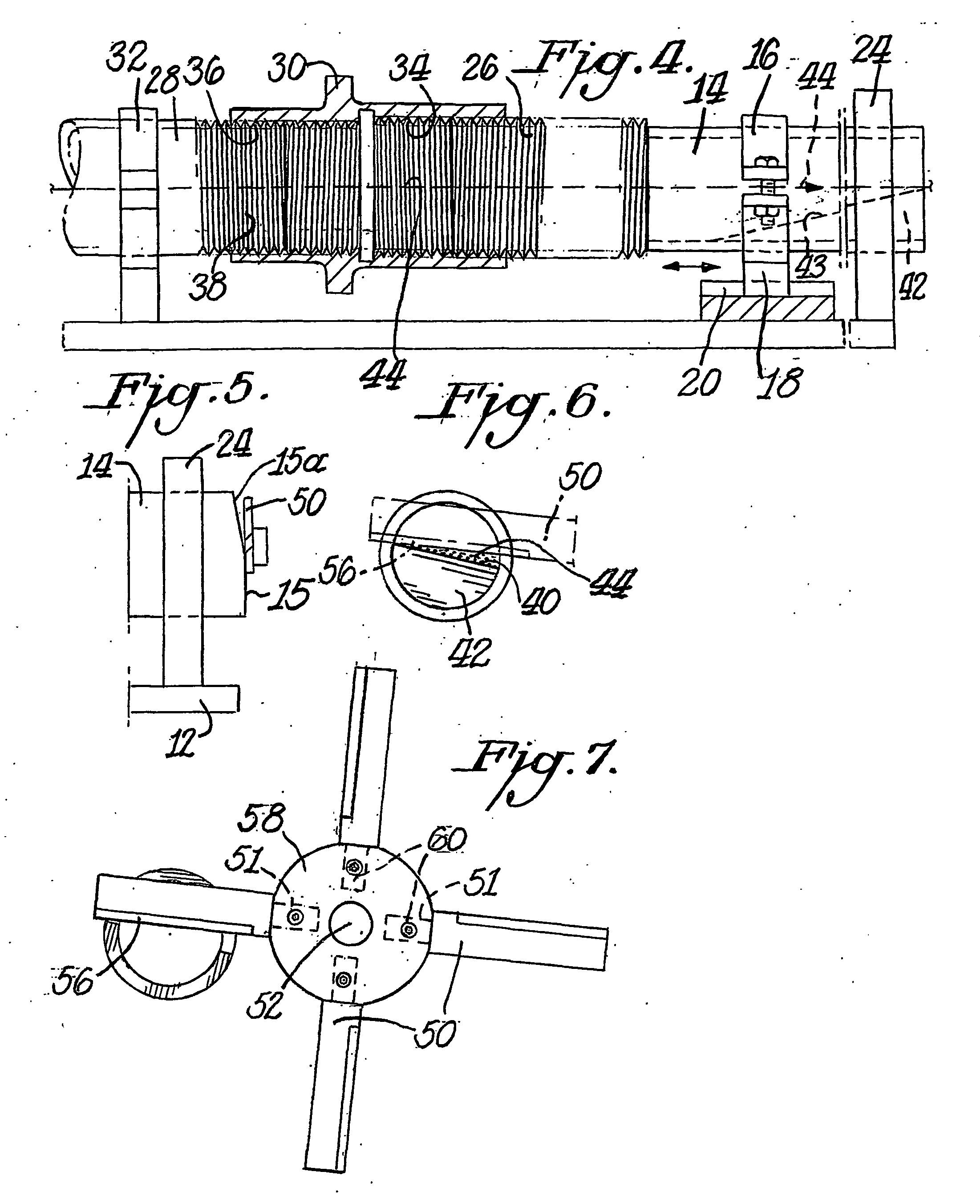

Method and apparatus for adjustable cutting of filamentary material

InactiveUS20070089575A1Readily operateFacilitate evaluationSevering to form staple fibresShearing machinesAirflowEngineering

A cutting apparatus for continuous lengths of filaments bundles, film ribbons, filamentary-type or other material in strip like form is disclosed containing a tube that is readily adjustable in very small increments relative to rotating blades. A housing surrounds the exit end of the tube and rotating blades which is attached to a suction device. The device creates a high velocity flow of air through the tube which aligns the filamentary material for cutting. An insert may be placed in the tube which contains an upper surface or anvil at its outer end. The tube and / or the insert in the tube is adjustable in two dimensions relative to one or more blades rotating in a plane transverse to the axis of the tube. These adjustments which may be made during operation of the cutting process to facilitate a cleaner, uniform cutting of the filamentary material.

Owner:BILLINGSLEY JOHN G S

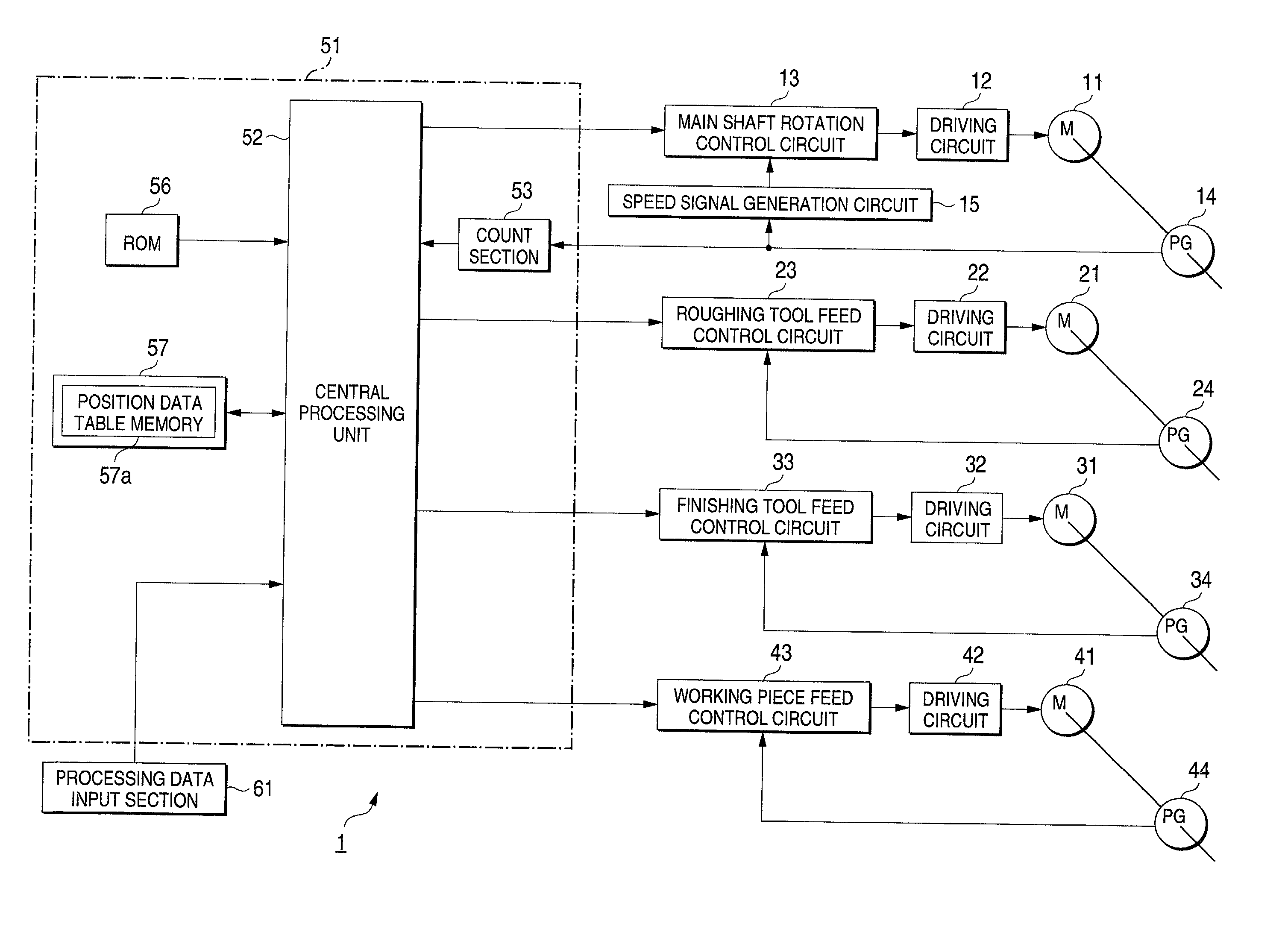

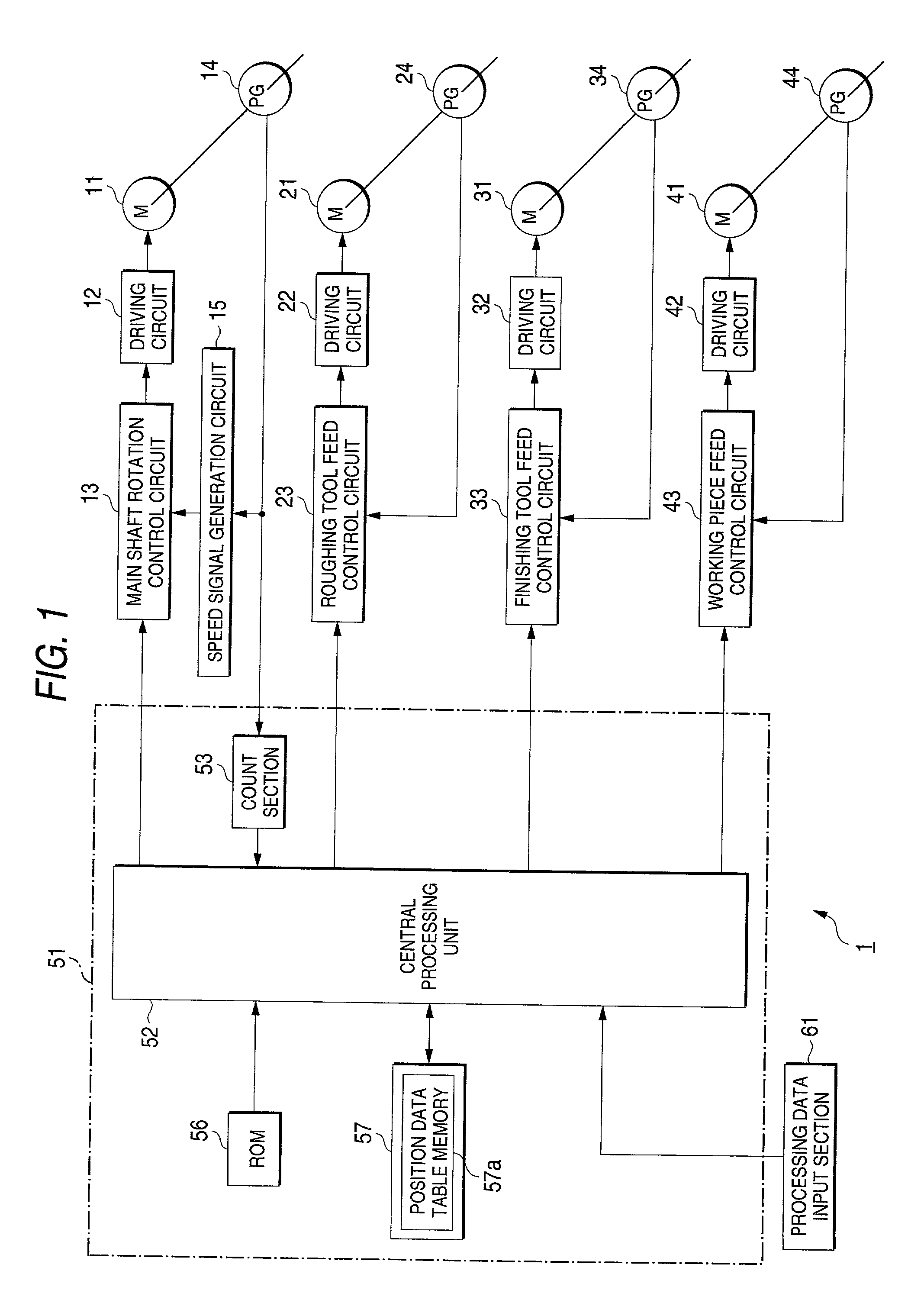

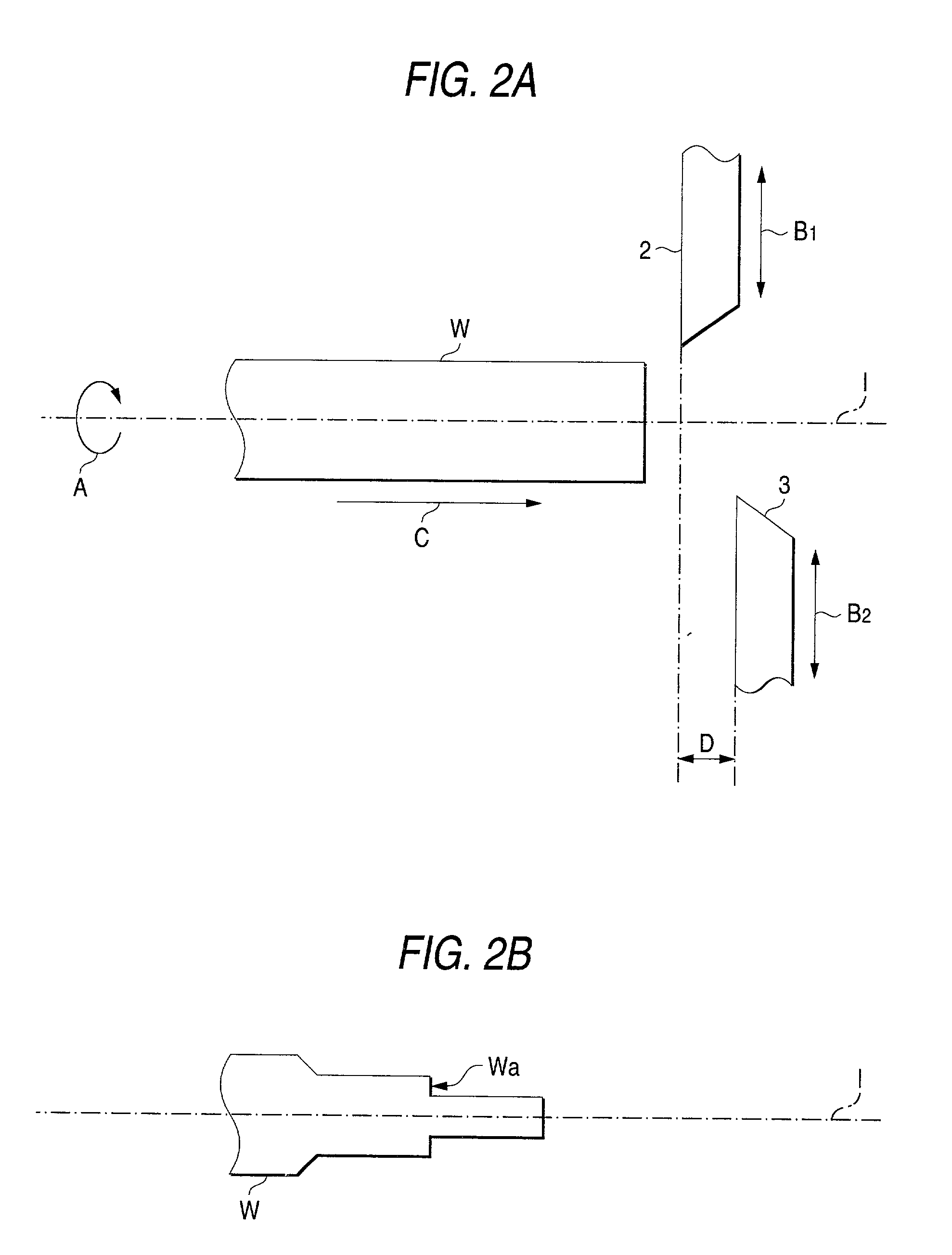

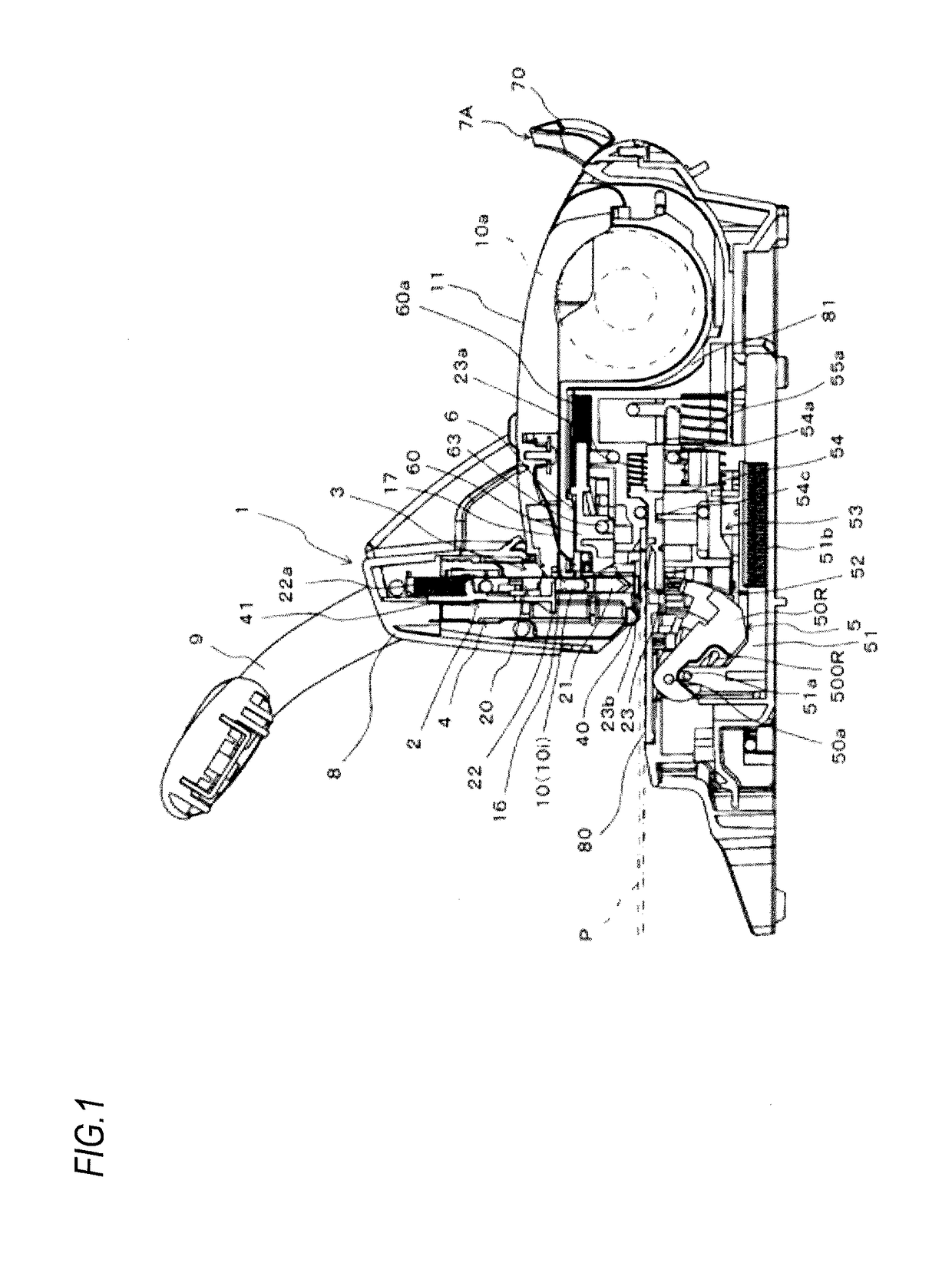

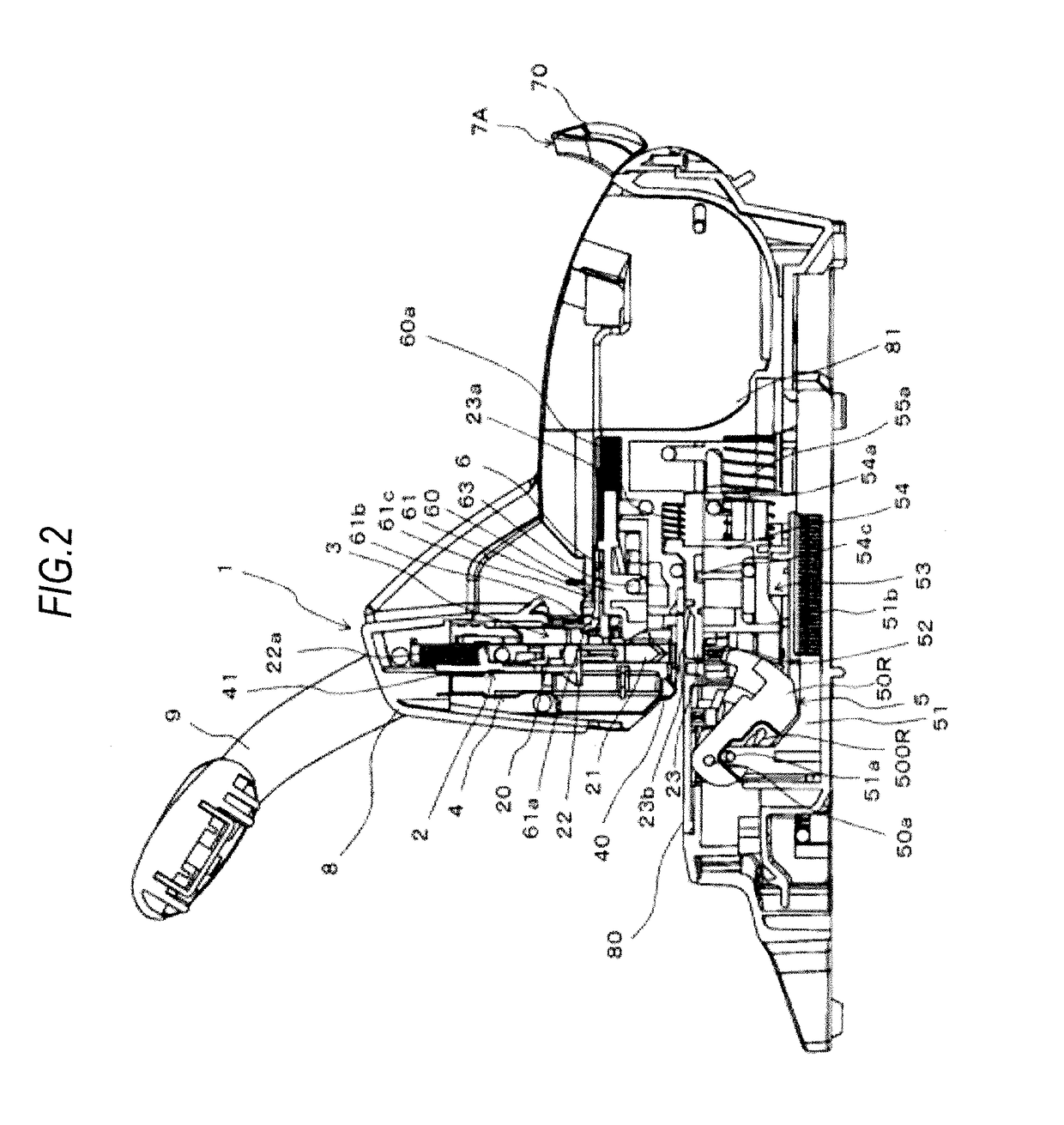

Tool path preparing method and machining method

InactiveUS20020025758A1Shorten the timeReduce processing timeAutomatic control devicesComputer controlEngineeringElectric motor

The movement position of the roughing tool is calculated, in S109, by adding the finishing allowance to the movement position of the finishing tool so that the path of the roughing tool is shifted in the direction perpendicular to the rotation center axis of the main spindle rotation motor from the path of the finishing tool by the finishing allowance. Then, a gap between the movement position of the roughing tool in the direction of the rotation center axis of the main spindle rotation motor and the workpiece W is calculated, and when the gap is not larger than a predetermined value G, in S113, the movement position of the roughing tool is corrected in the direction perpendicular to the rotation center axis of the main spindle rotation motor so that the roughing tool does not cut in the inside of the finishing portion of the workpiece. The movement position of the roughing tool is corrected so that the movement speed of the roughing tool in the direction perpendicular to the rotation center axis of the main spindle rotation motor is a predetermined value.

Owner:STAR MICRONICS

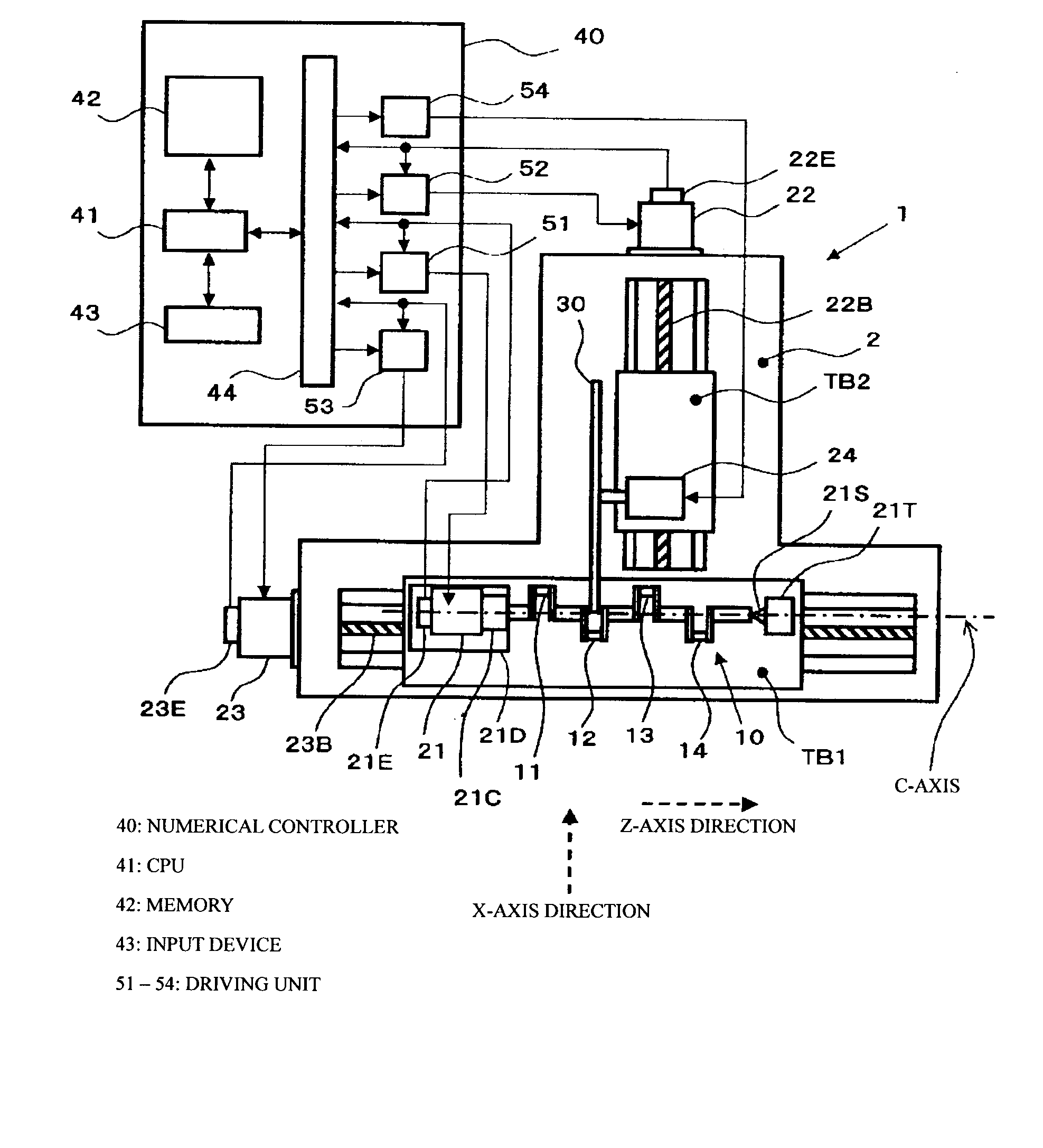

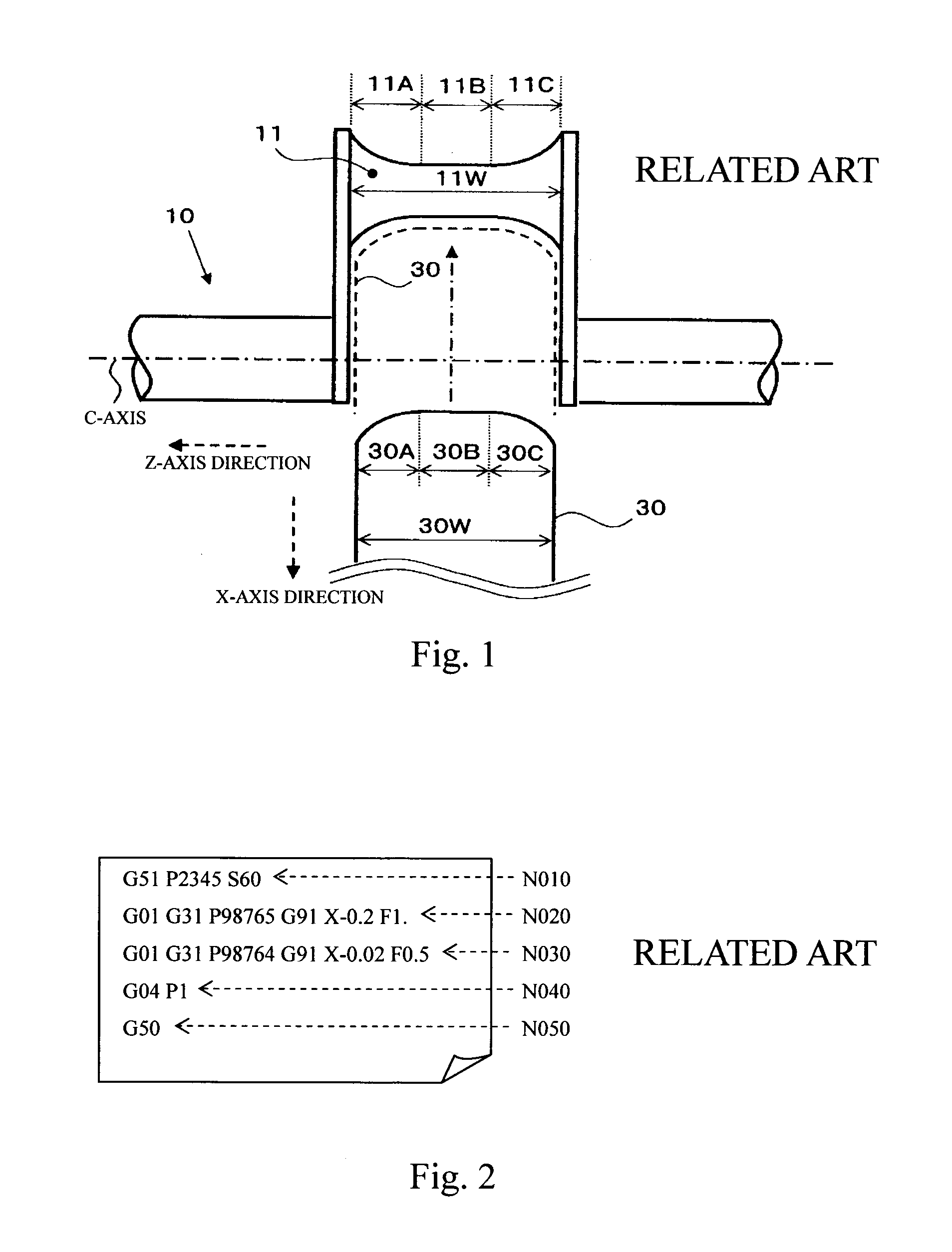

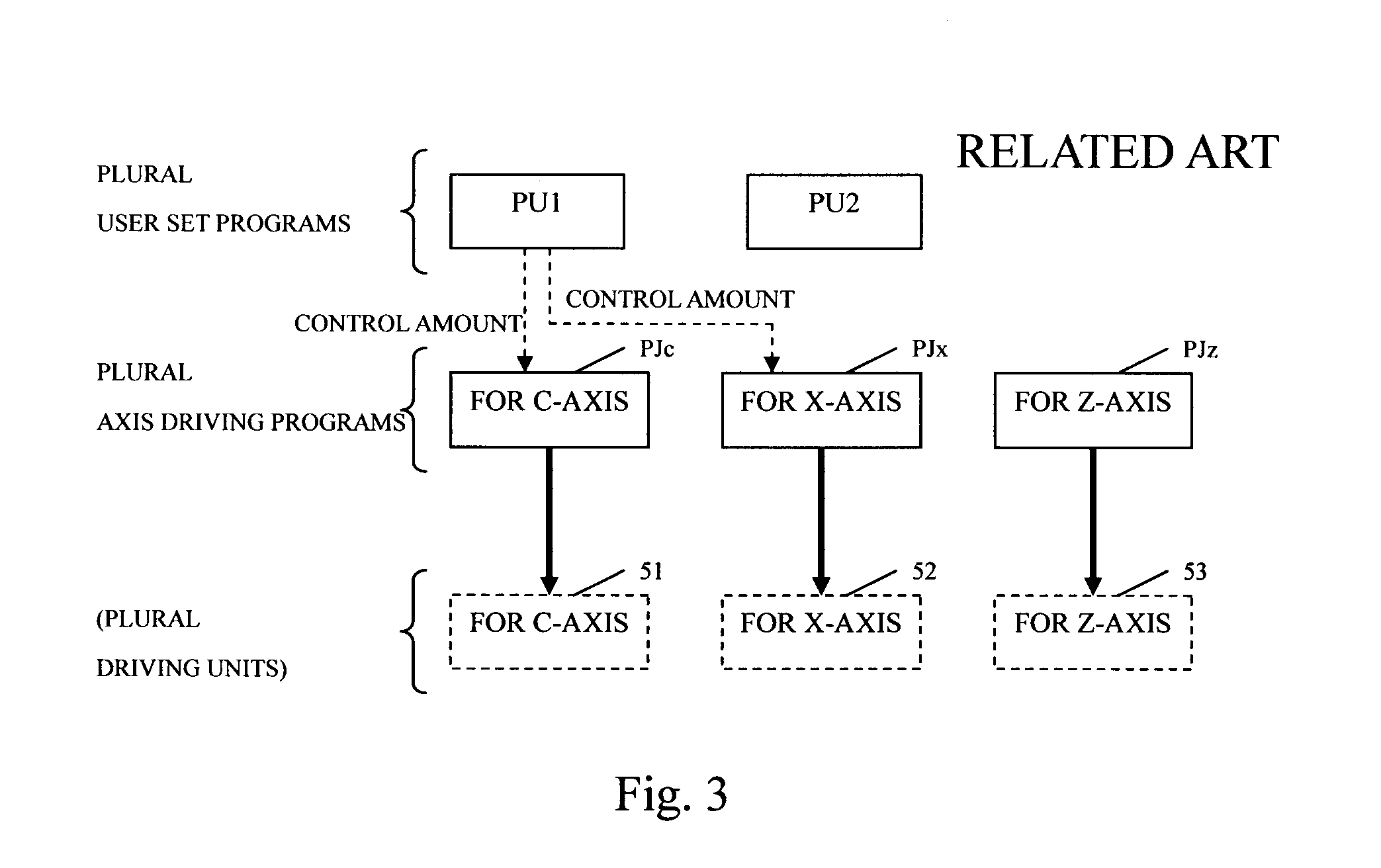

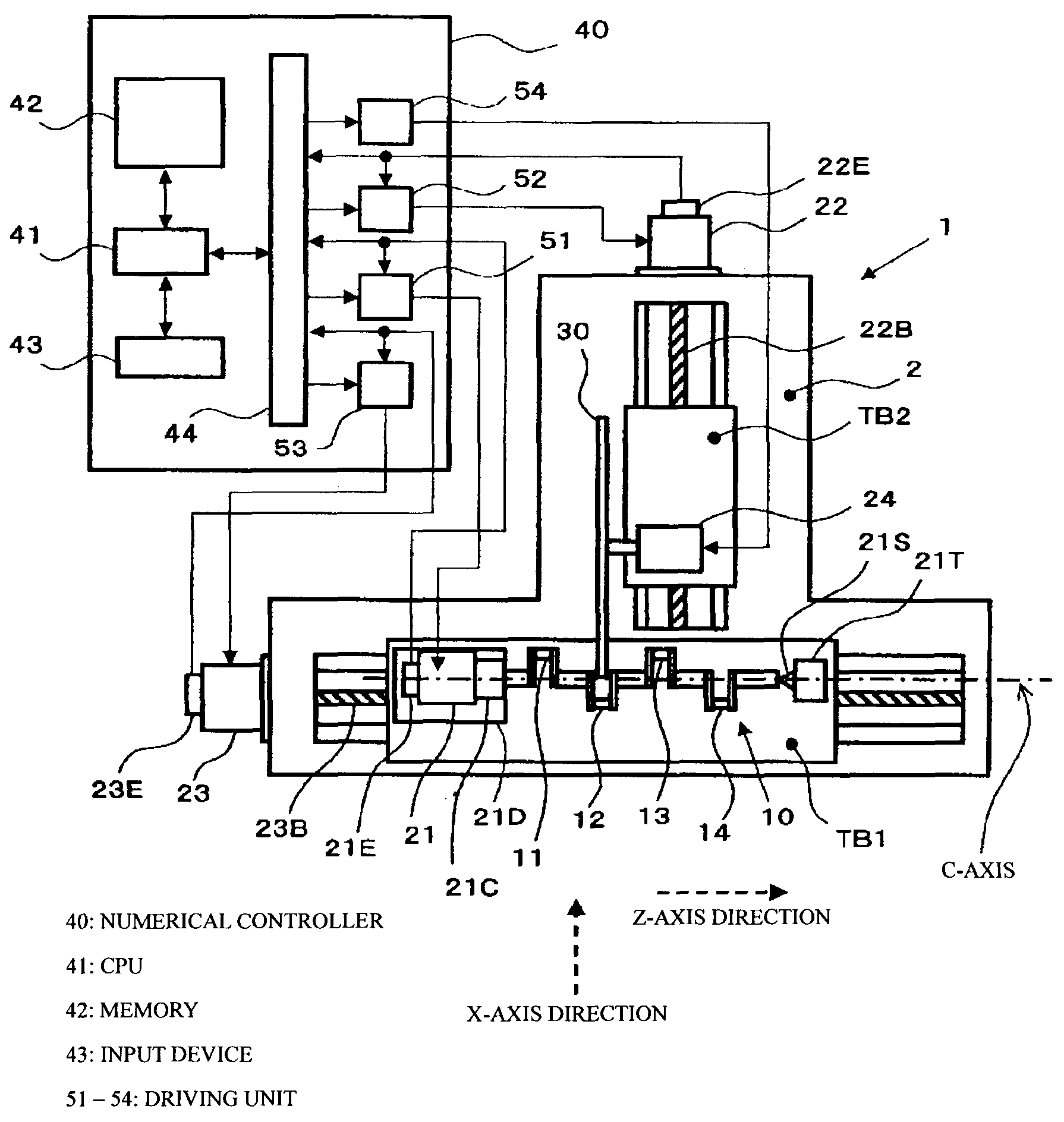

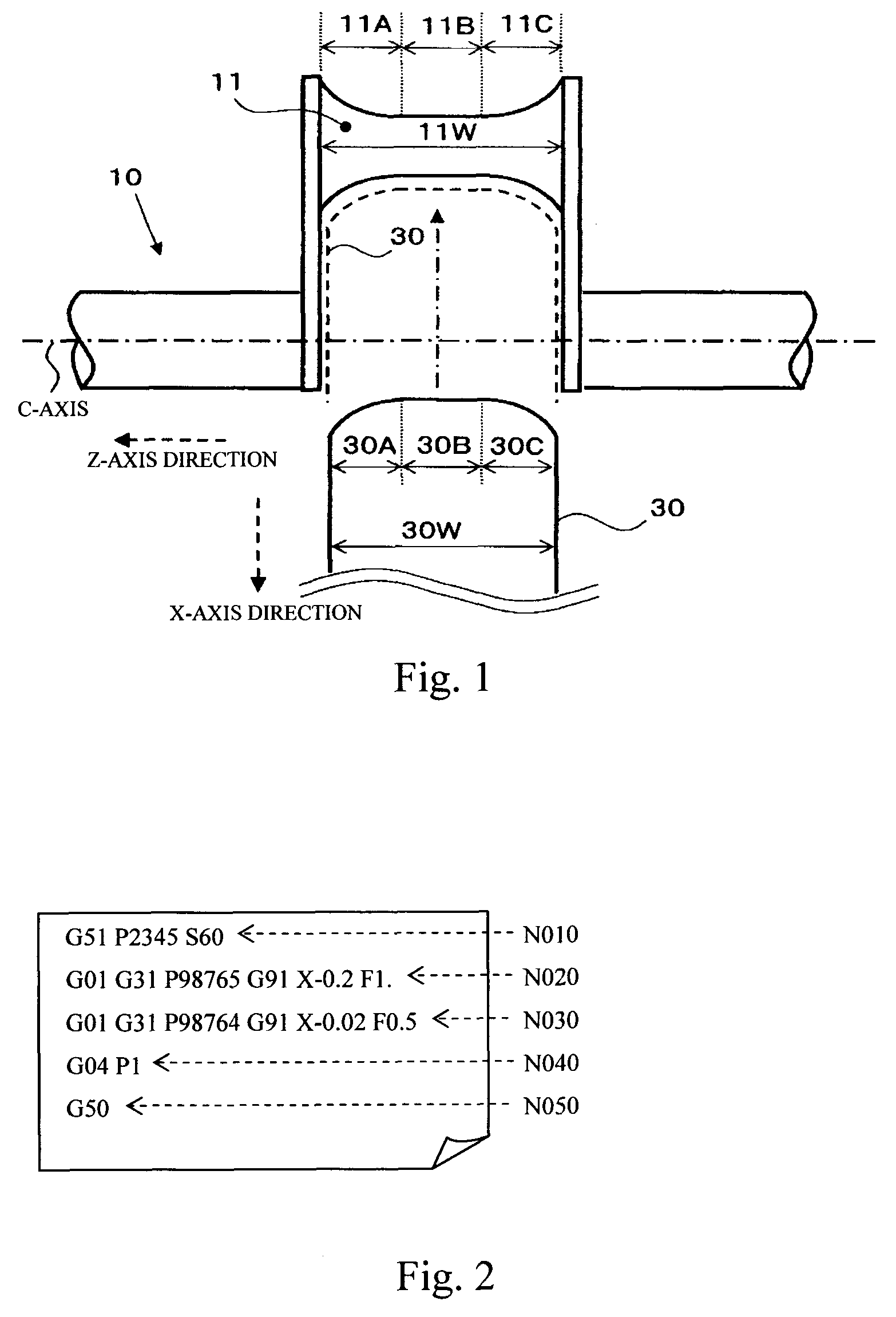

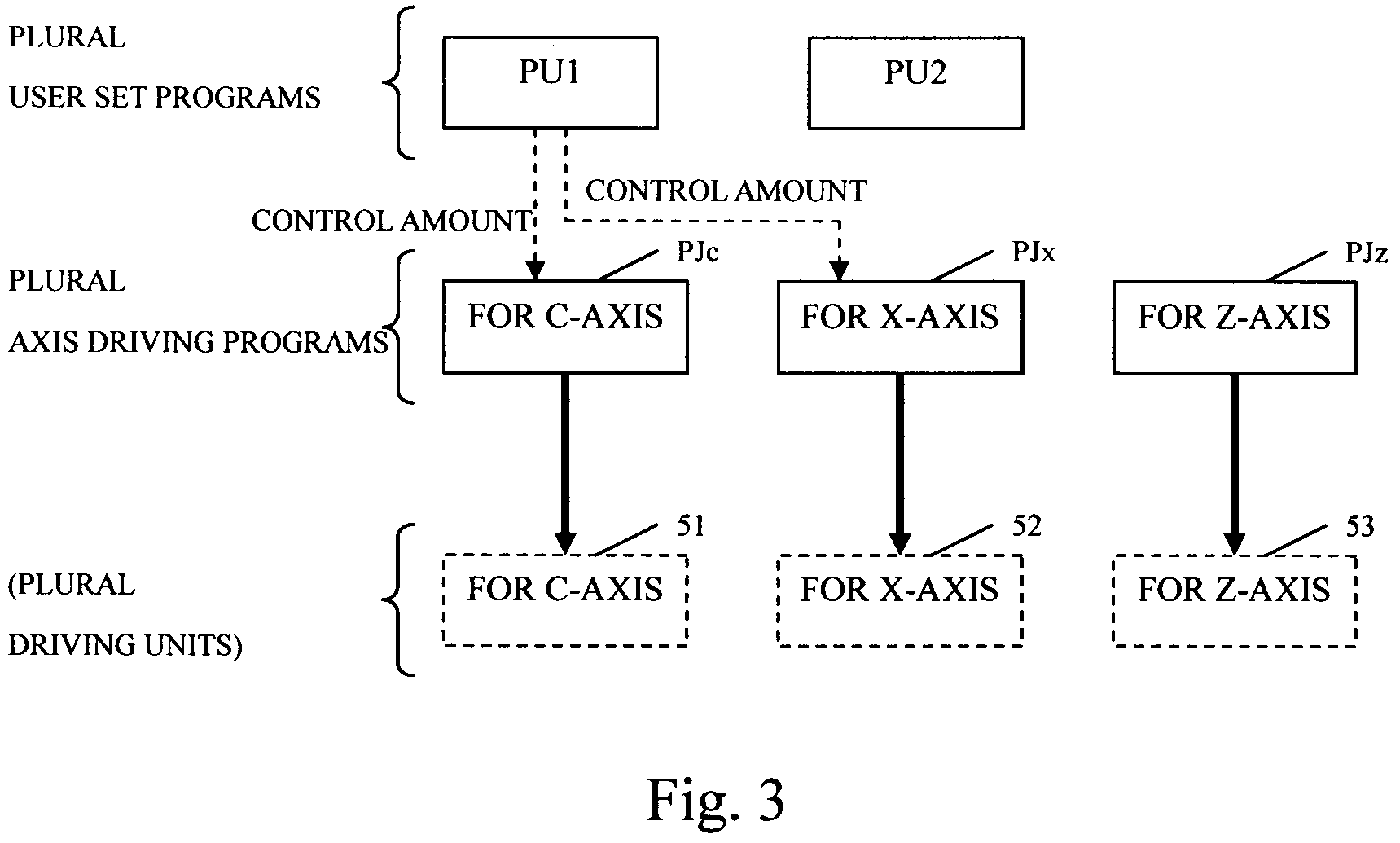

Program writing method of numerical controller, numerical controller and cutting machine controlled thereby

ActiveUS20080177407A1Improve accuracyReduce cutting loadProgramme controlGrinding feed controlMachine controlProcedural approach

It is one object of the present invention to provide a program writing method of numerical controller, a numerical controller and a cutting machine controlled thereby achieving to write a plurality of programs relating to one axis to perform a high efficiency in the small lot of productions.A next or later user-set-program controlling a duplicated axis controlled by plural user set programs identifies a virtual axis virtually controlled by own user set program, a program is written to replace the duplicated axis to the virtual axis. A control amount calculated by the user set program identifying the virtual axis is added to a control amount input to a correspondent axis driving program as a control amount of duplicated axis before replacing to the virtual axis.

Owner:JTEKT CORP

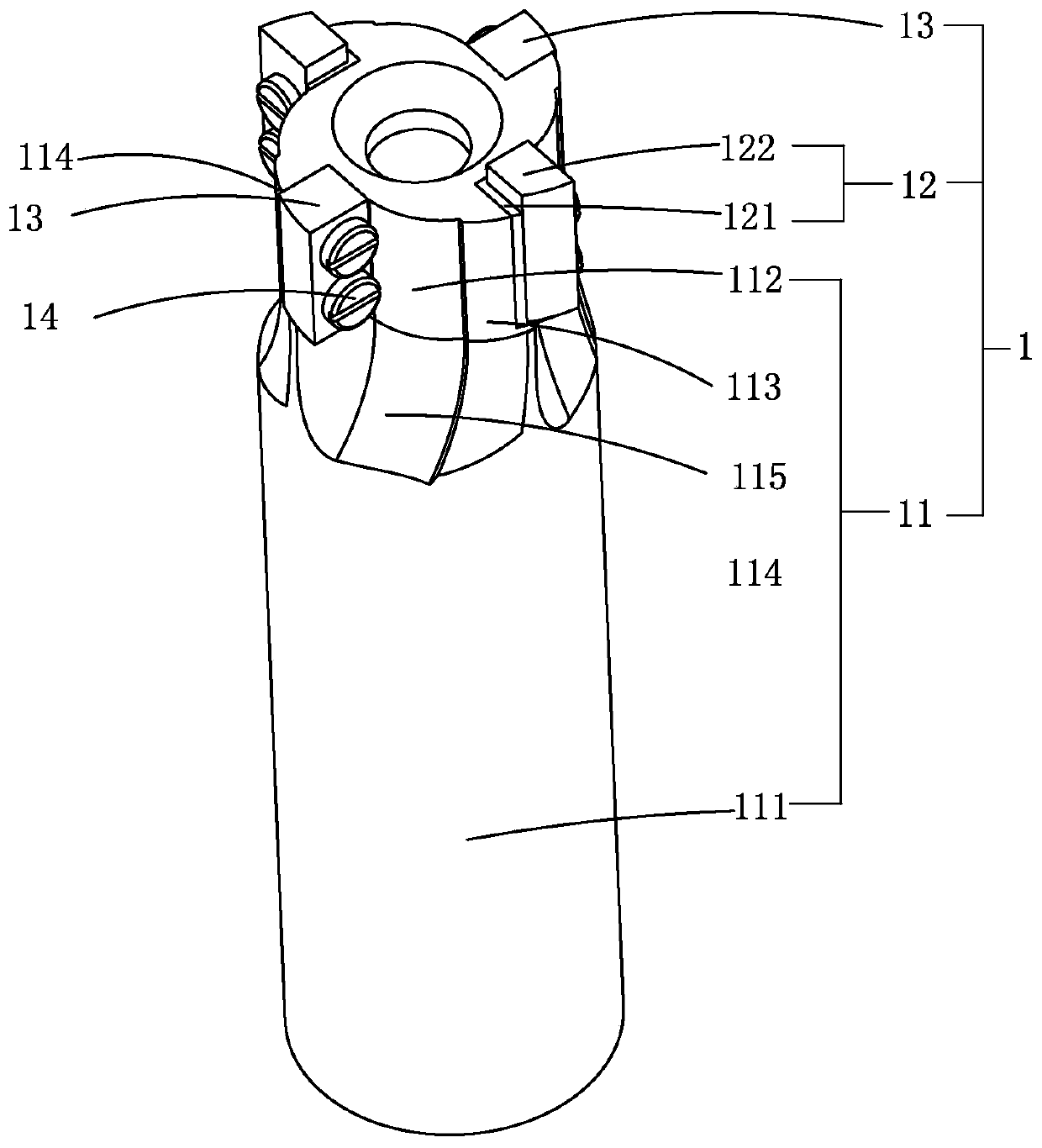

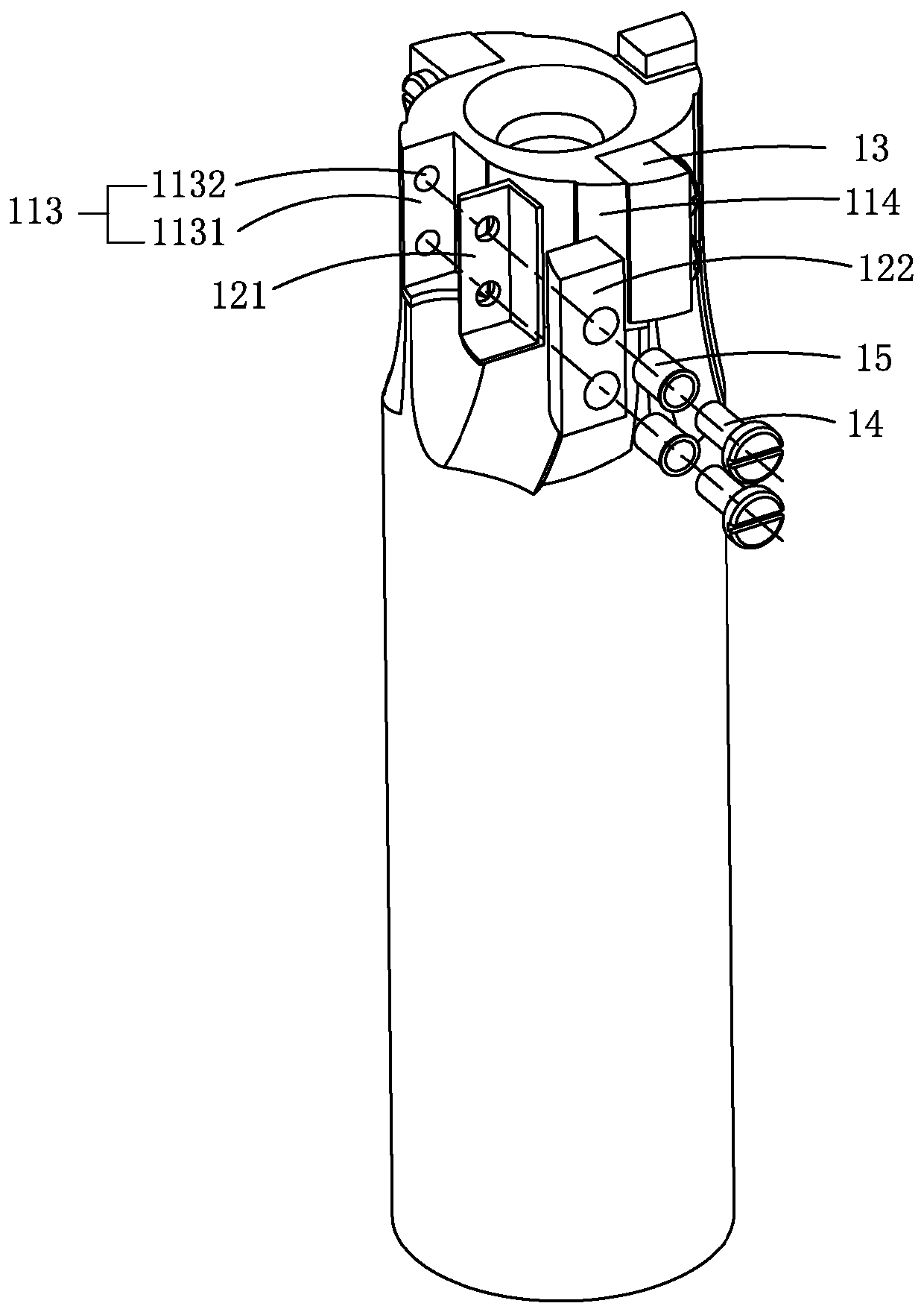

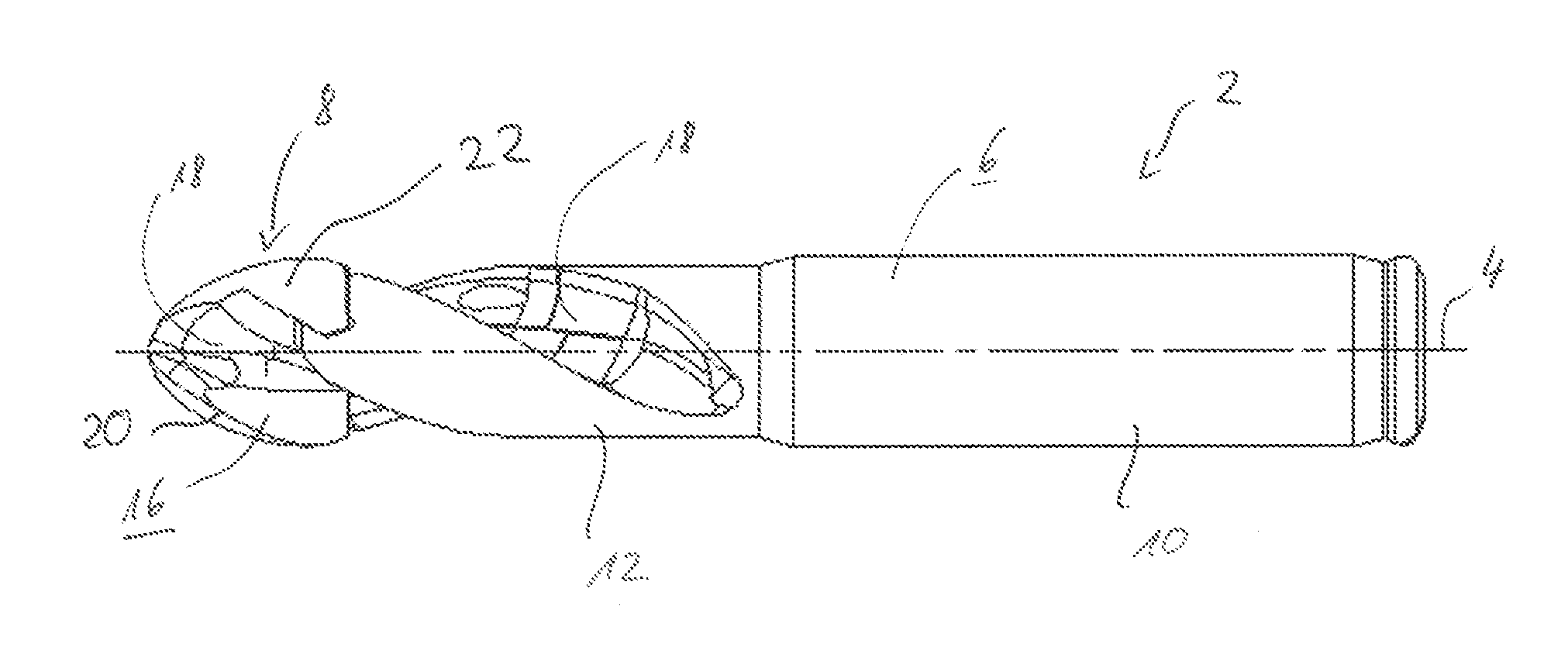

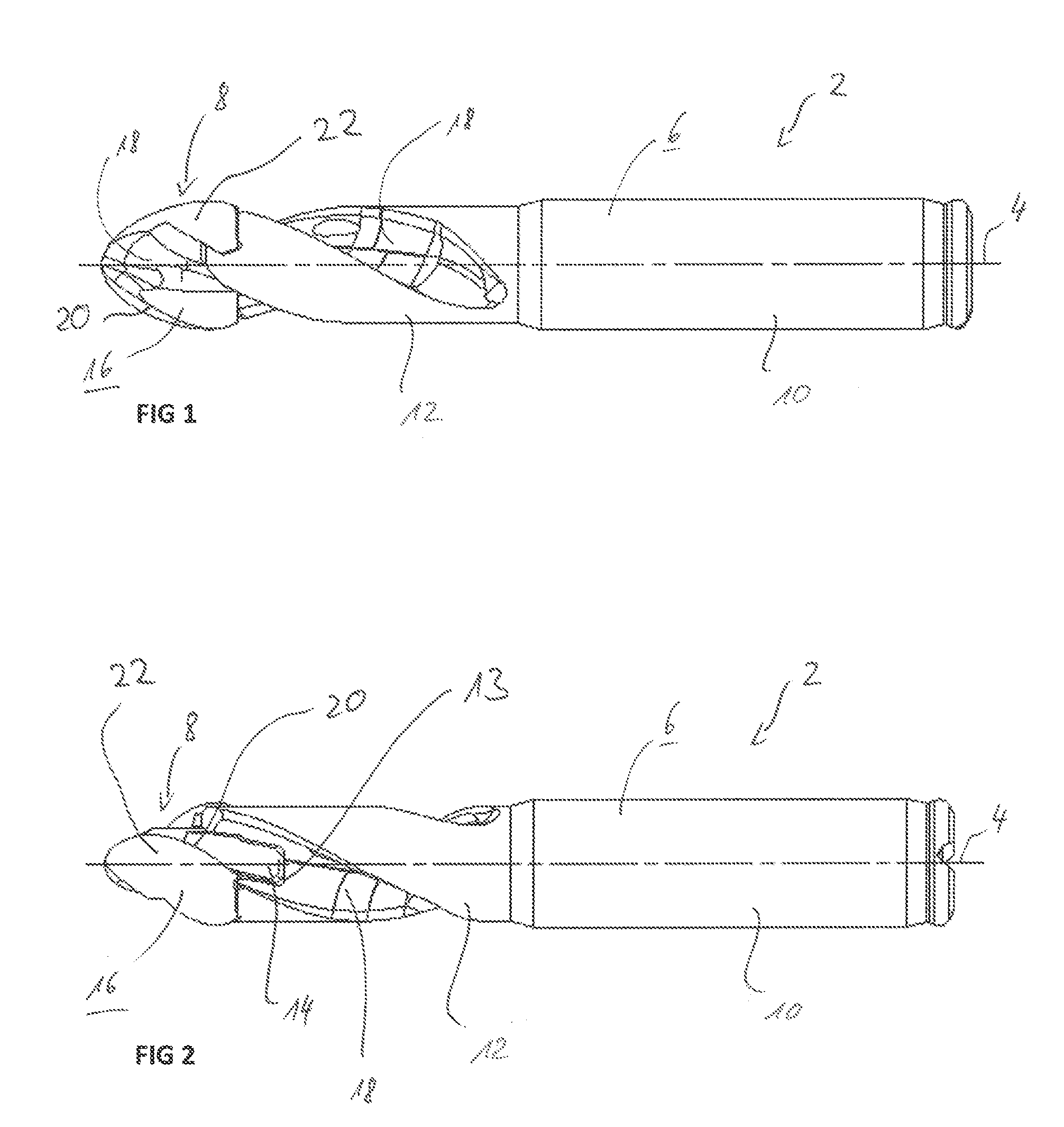

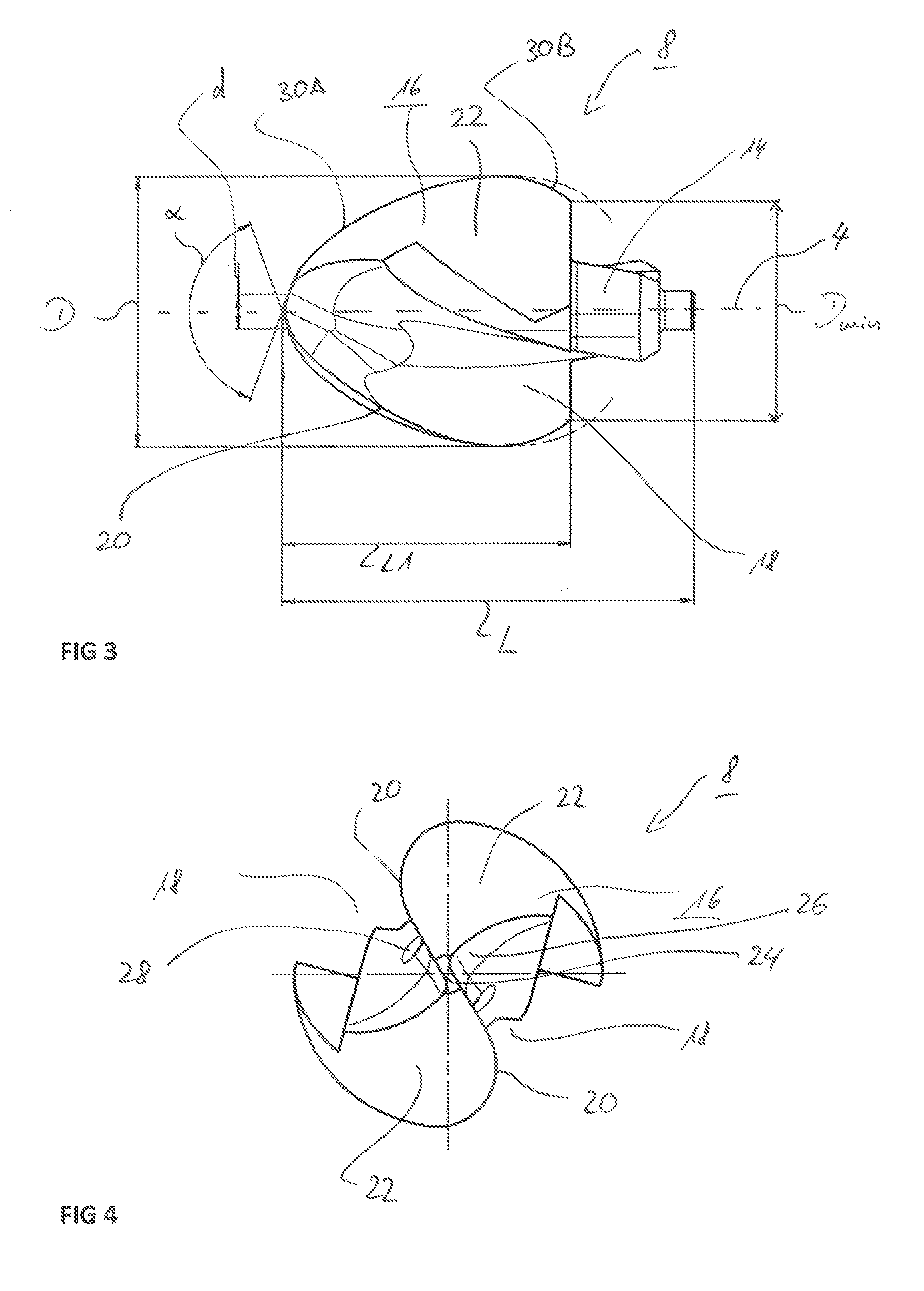

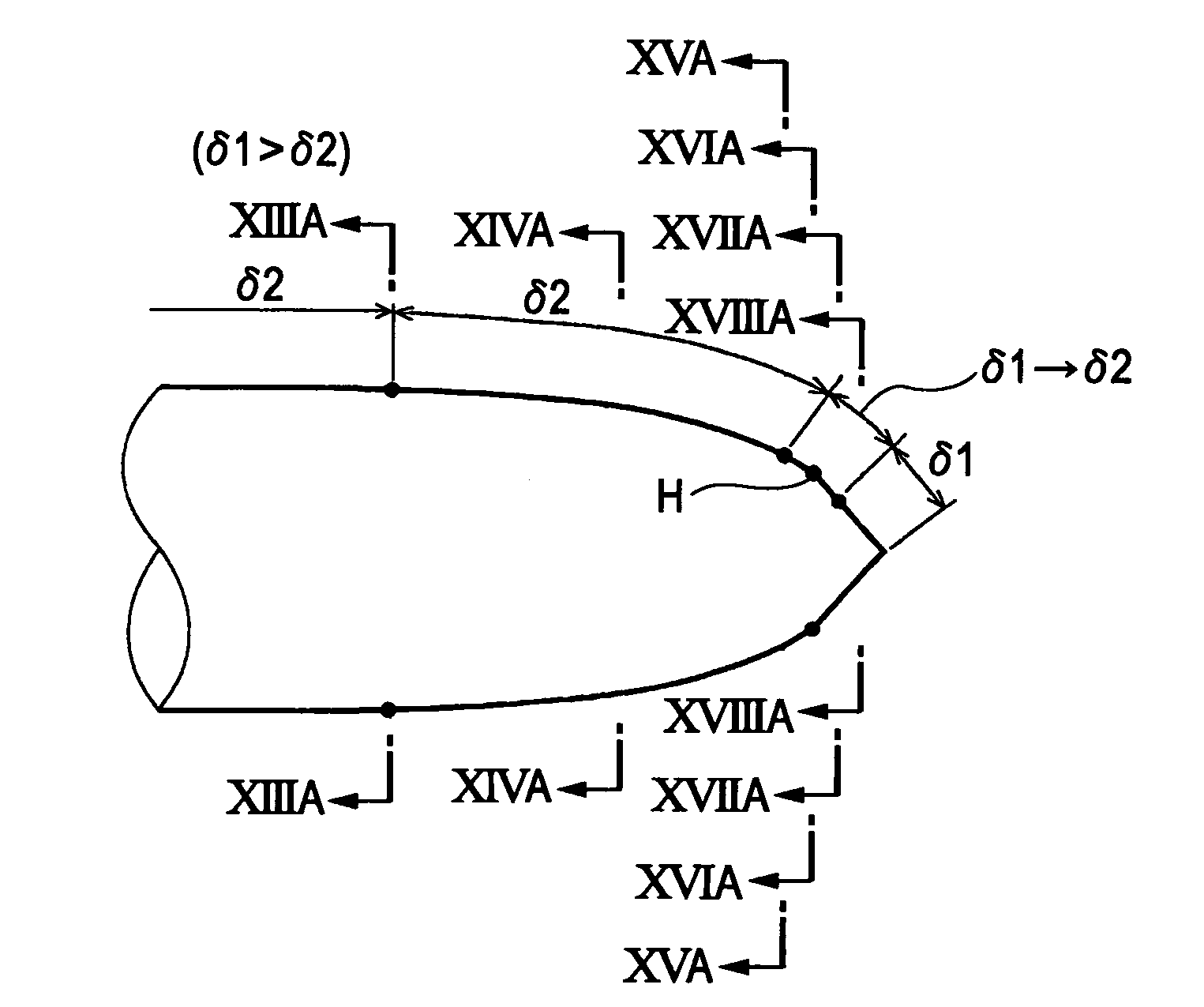

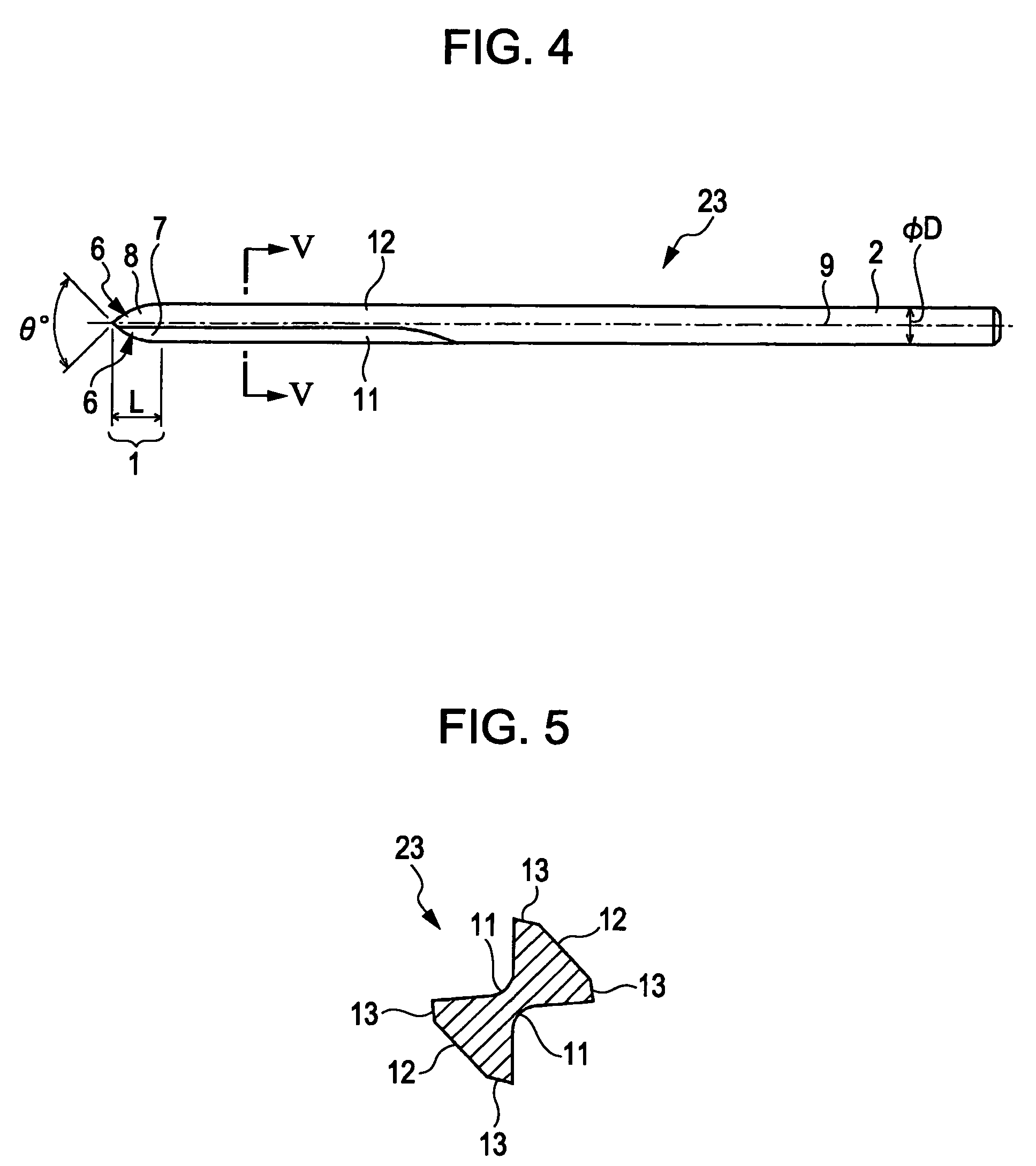

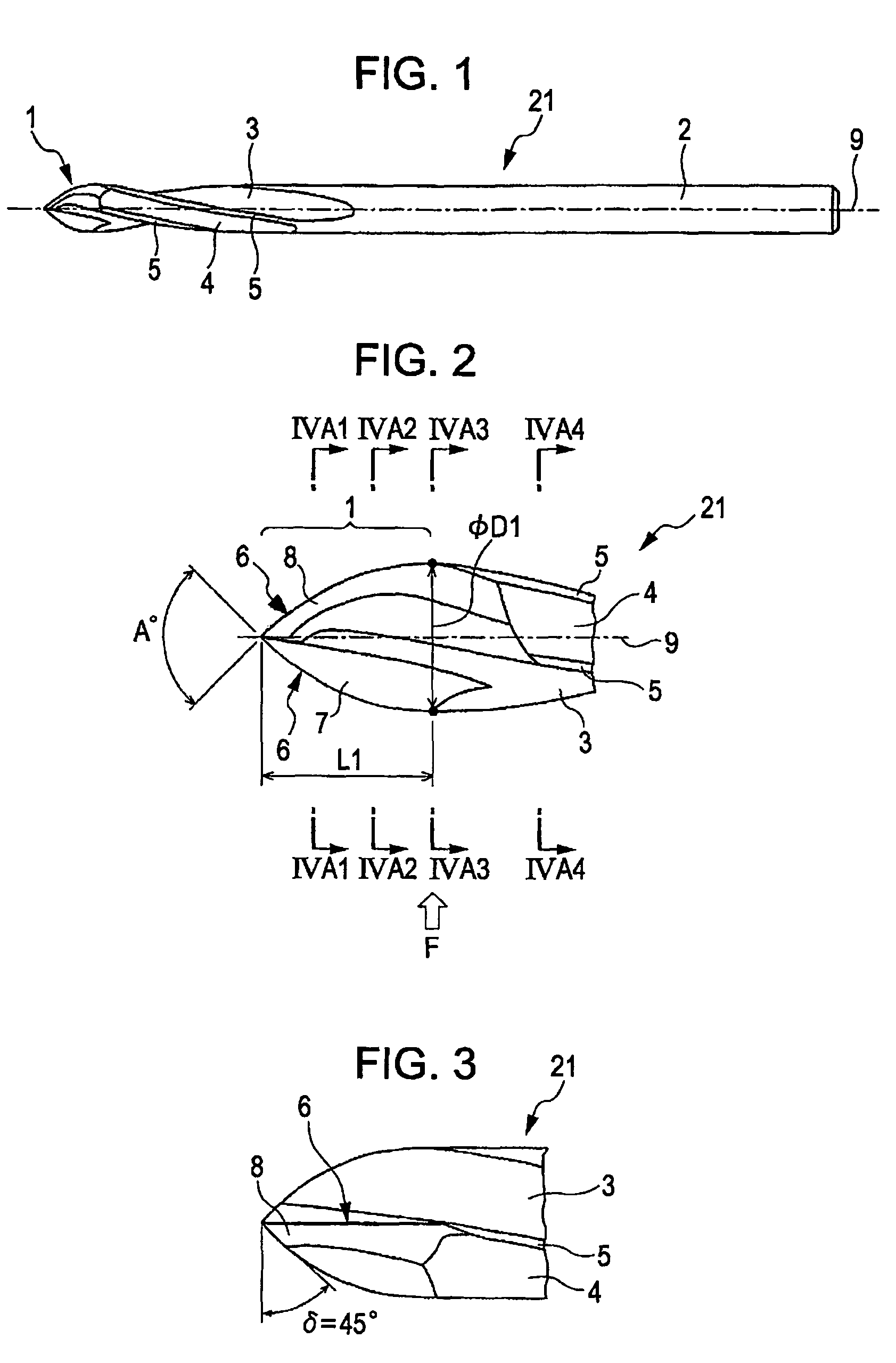

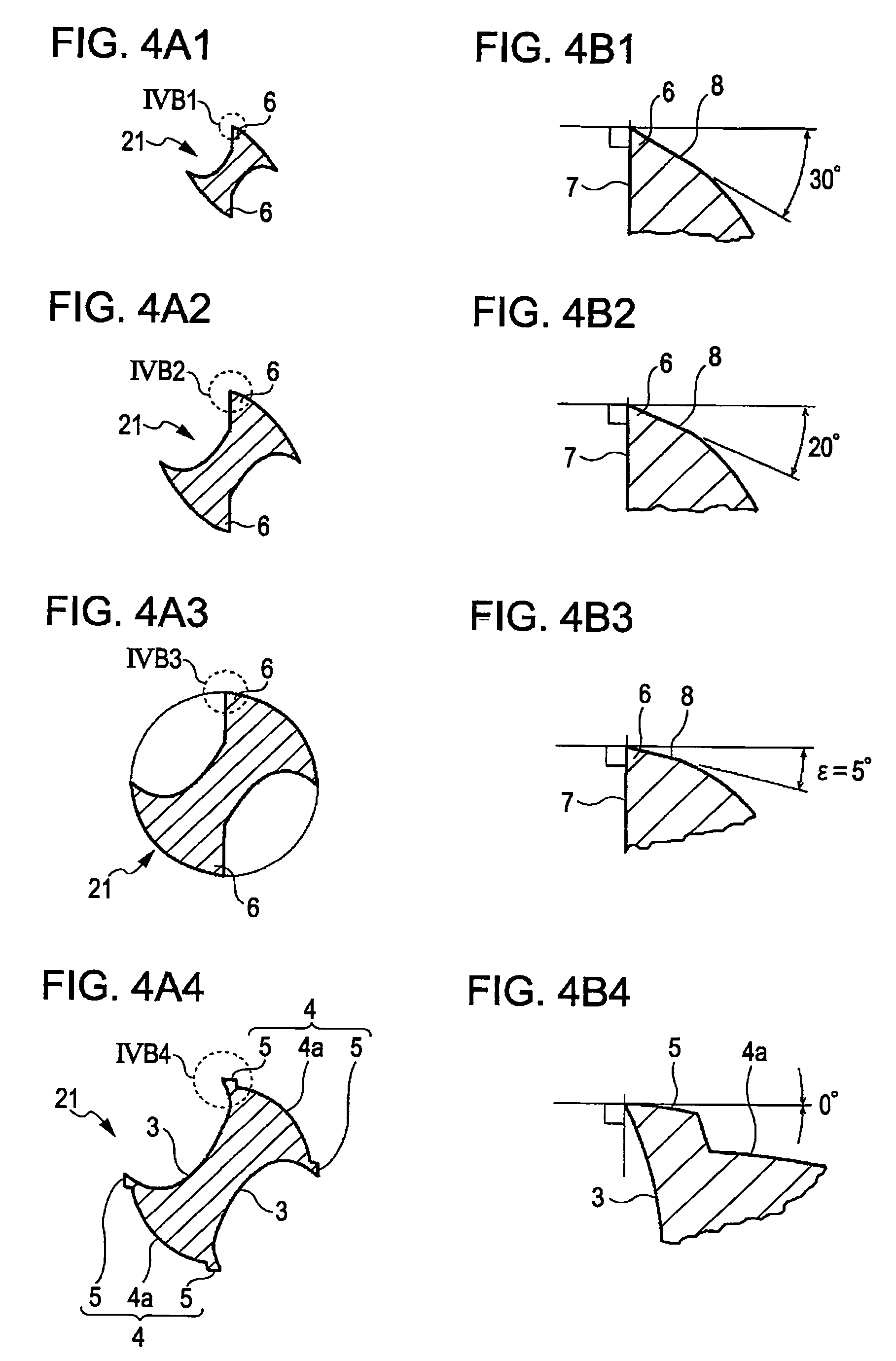

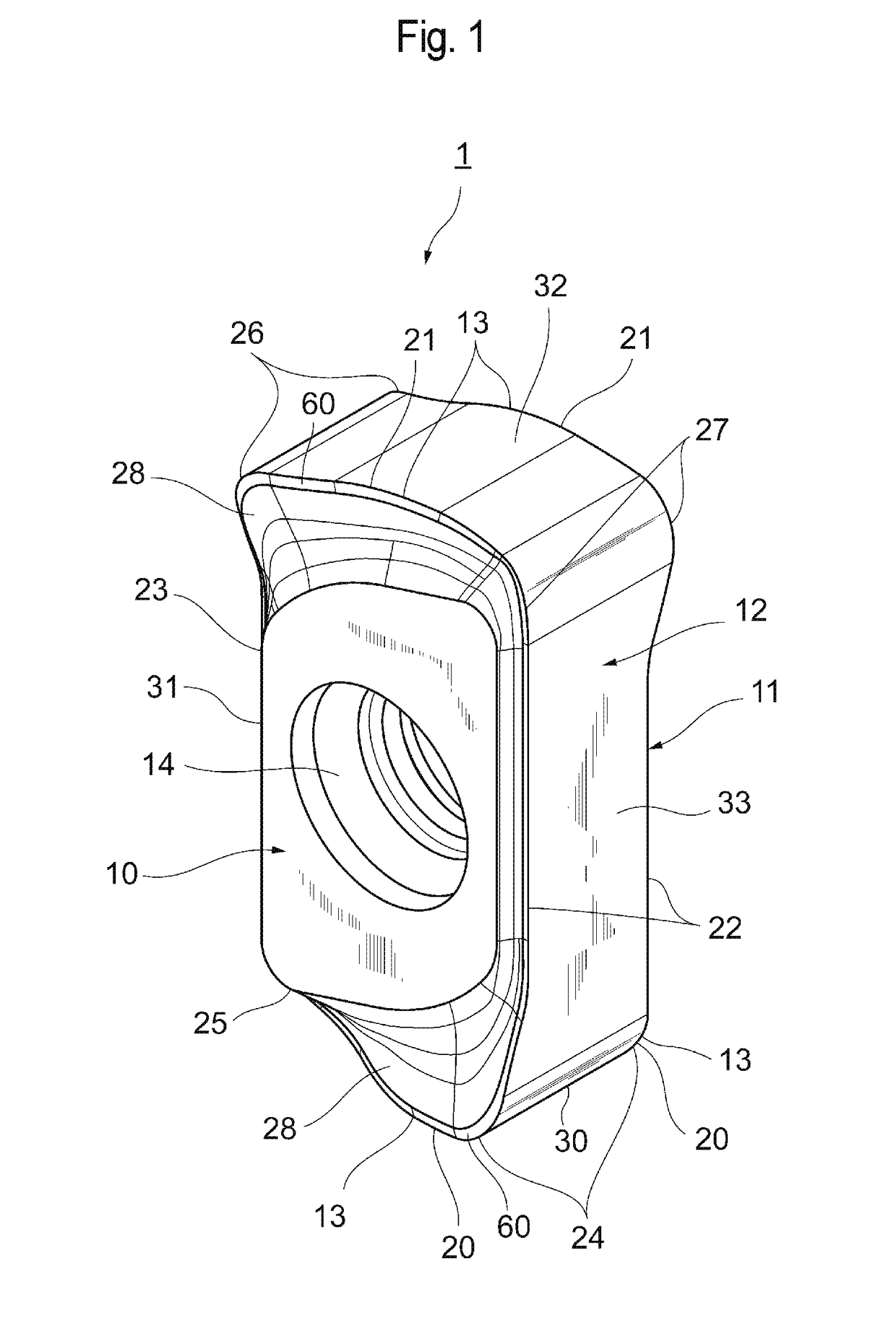

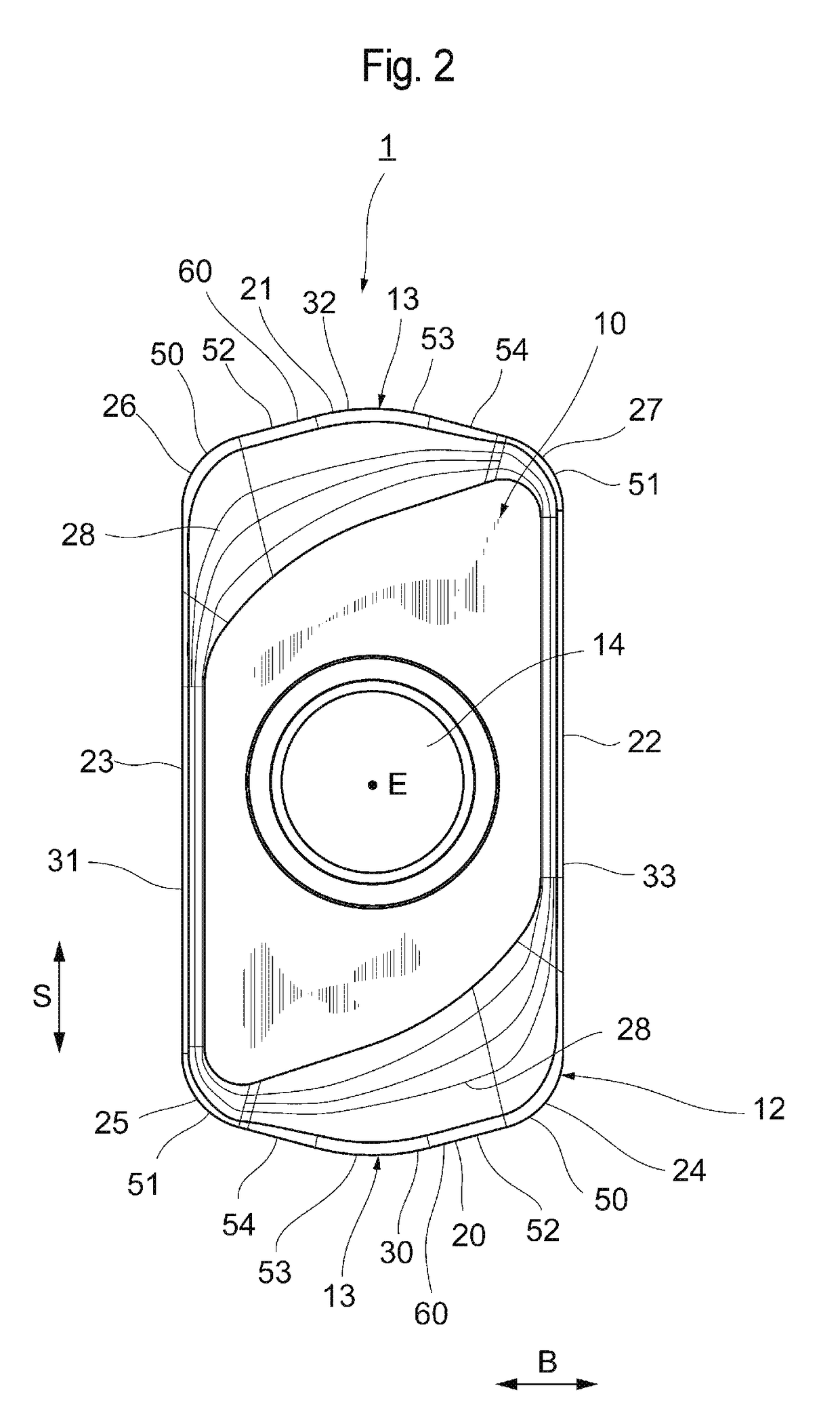

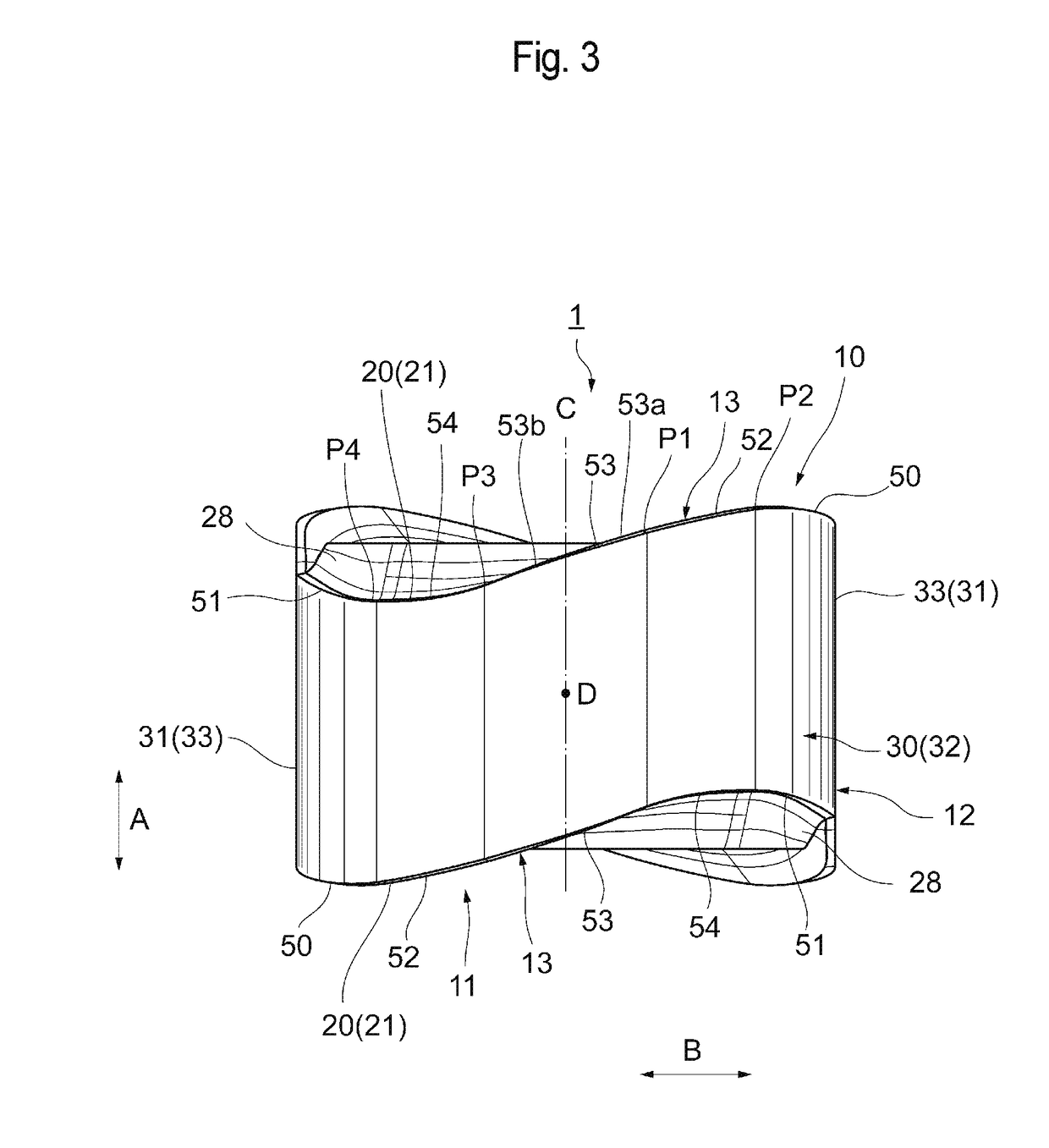

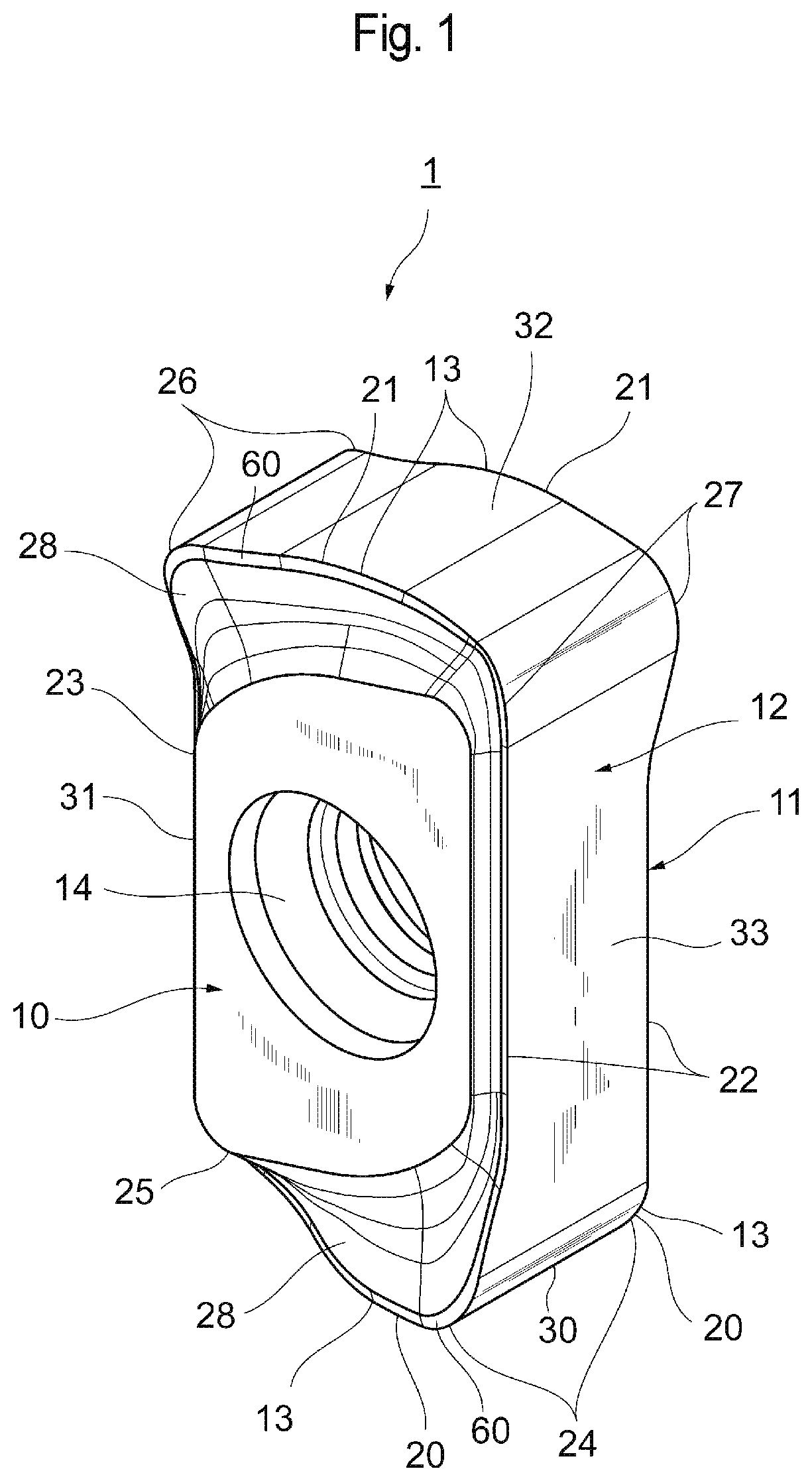

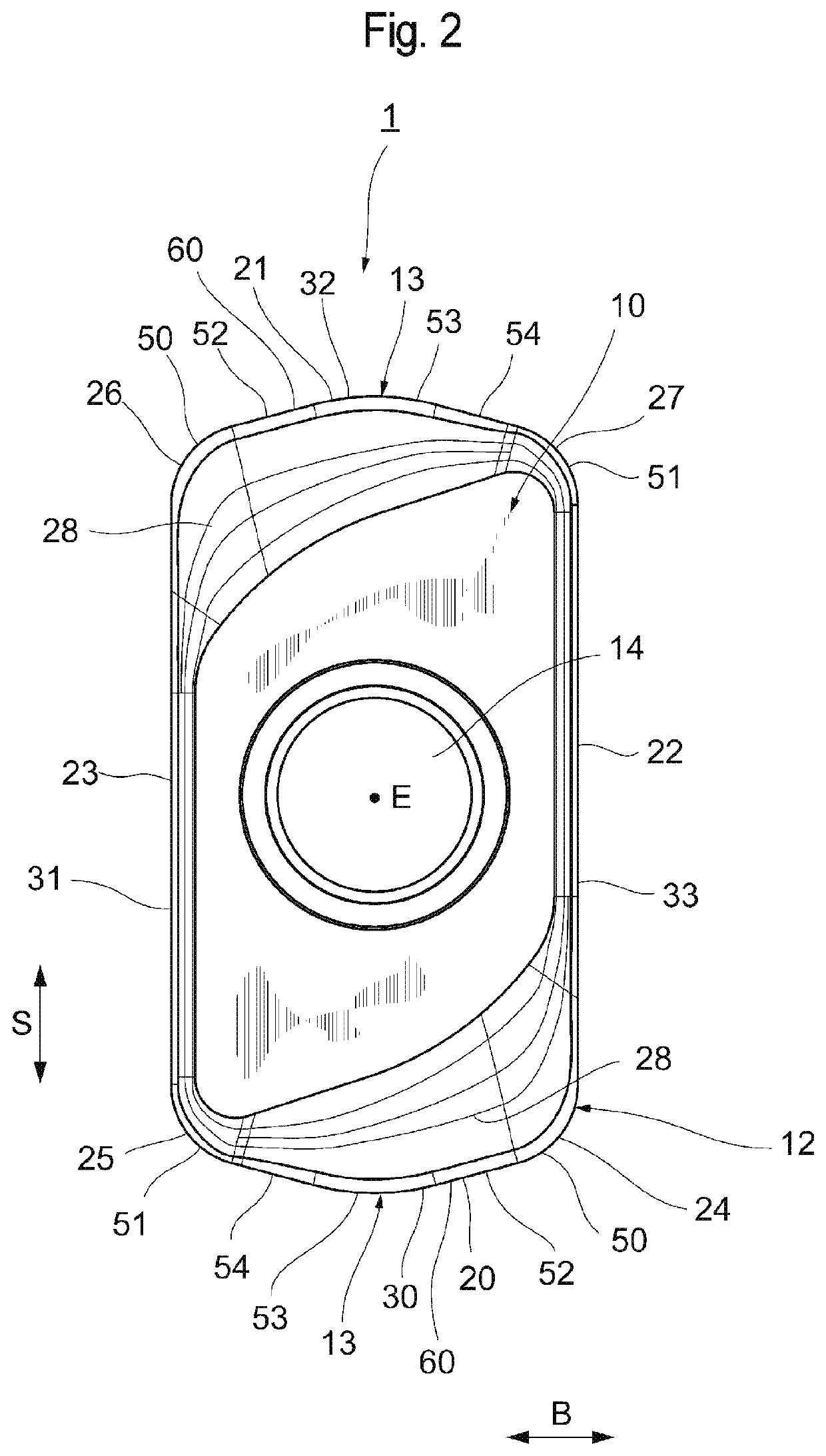

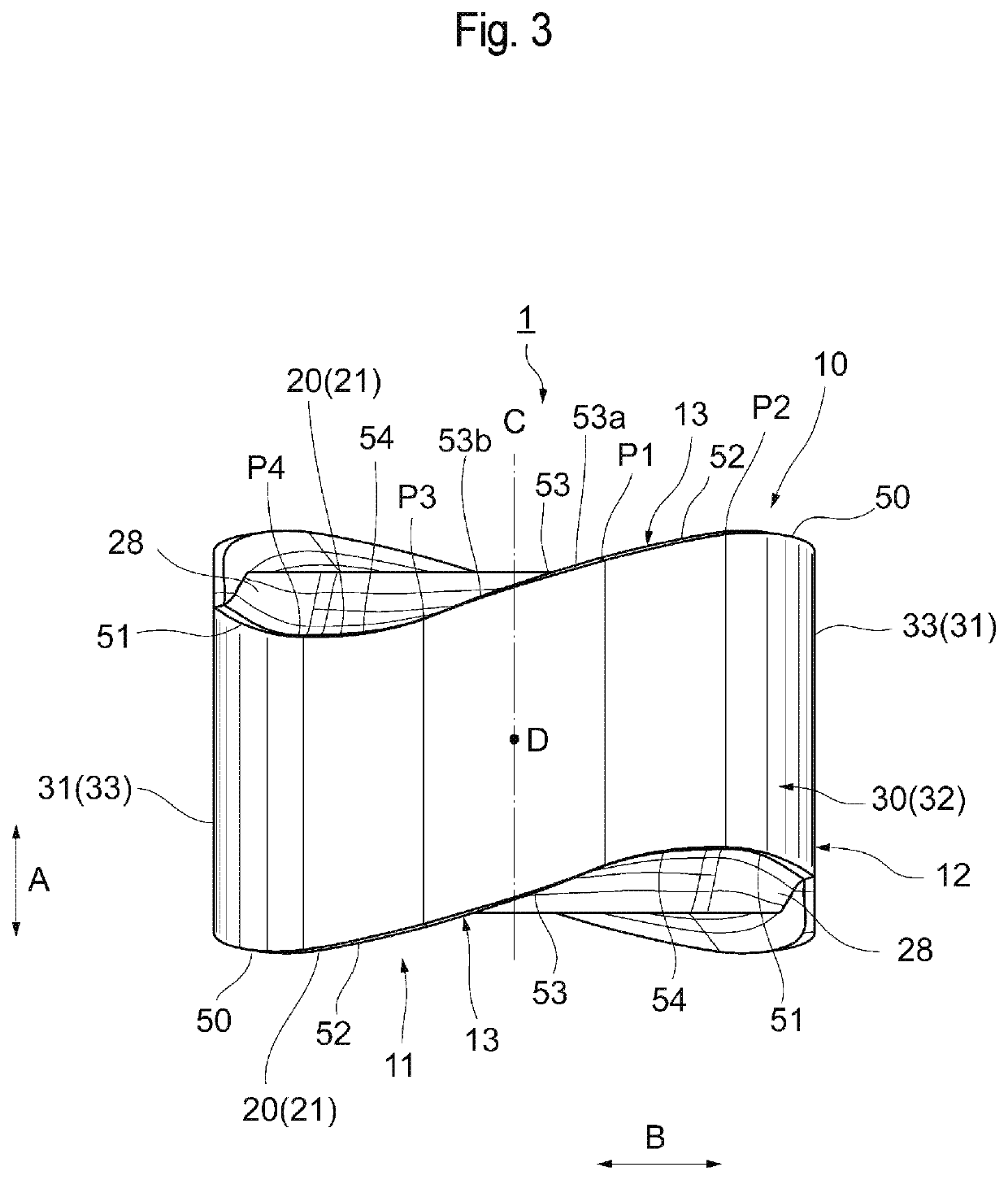

Tool head and method for machining a metallic workpiece

ActiveUS20140294527A1Less loadHigh rateWood turning toolsTransportation and packagingSwarfEngineering

A tool head includes an ovoid basic element disposed about a center axis, at least two chip grooves formed in the basic element, and a number of major cutting edges. Each major cutting edge is disposed in a convex course along a respective chip groove of the at least two chip grooves. The major cutting edges define with their radially outermost region a nominal diameter. A radial distance from each major cutting edge to the center axis in a front, tip-side, arc portion increases up to the nominal diameter and in a rear, shank-side, arc portion decreases back down to a minimum diameter.

Owner:KENNAMETAL INC

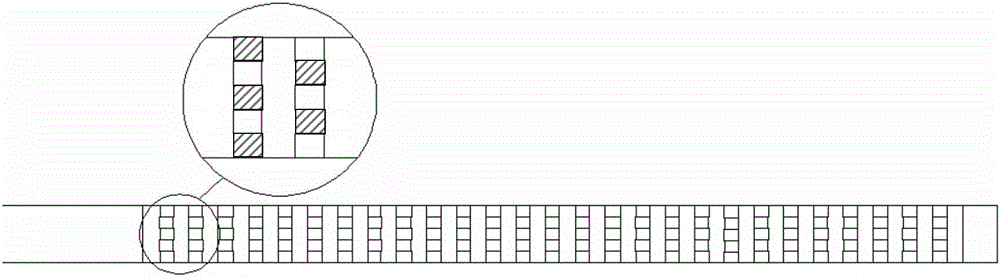

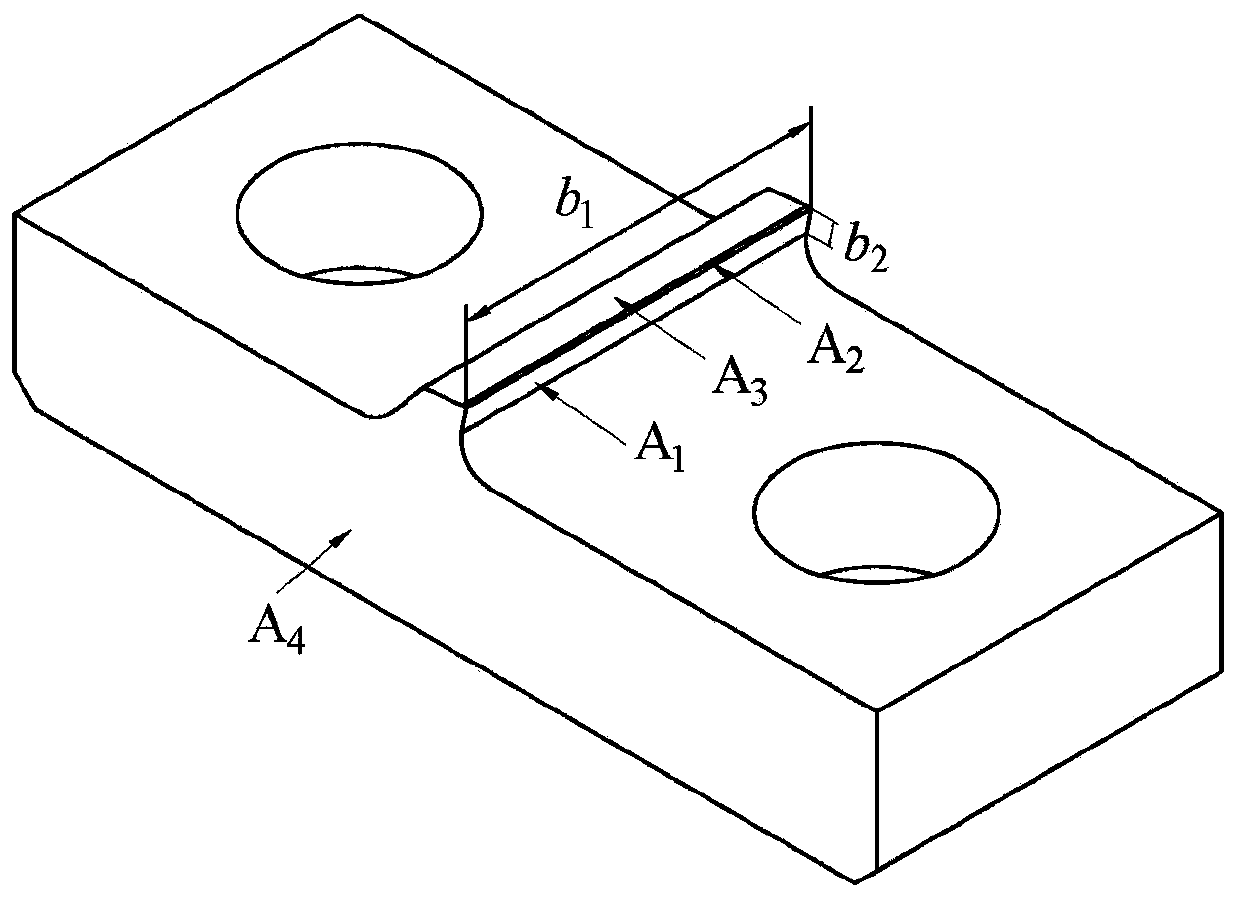

Cobweb-like microstructure broach with gradient wetted surface and preparation method thereof

ActiveCN111230213AImprove wettabilityReduce cutting loadBroaching toolsLaser beam welding apparatusMicrostructureFiber

The invention discloses a cobweb-like microstructure broach with a gradient wetted surface and a preparation method thereof. Researches show that some microstructures with specific shapes are formed on the surface of the material, so that the effect of improving the hydrophobicity or hydrophilicity of the material can be achieved. The cobweb-like microstructure broach with high wettability comprises a cutter base body and cutter tooth blocks. One or more cutter tooth blocks are installed on the cutter base body. Broach teeth are arranged on the cutter tooth blocks. Cobweb-like microstructure is arranged on the front cutter face of the broach teeth; and the cobweb-like microstructure comprises m transverse grooves and n longitudinal grooves. The m transverse grooves and the n longitudinal grooves are staggered to form a grid shape. Each intersection point is provided with a node pit. Hydrophilic fiber strips are arranged in the m transverse grooves and the n longitudinal grooves. According to the cobweb-like microstructure broach, the cobweb-like microstructure is formed in the front cutter face of the broach and carbon fibers are combined, the wettability of the surfaces of the cutter teeth is improved, the cutting load is reduced, and the effects of reducing abrasion of the broach and prolonging the service life of the broach are achieved.

Owner:HANGZHOU DIANZI UNIV

Drill

ActiveUS9168593B2Improve performanceImprove cutting performanceWood turning toolsTransportation and packagingEllipseEngineering

A drill includes a cutting edge having a ridgeline. The ridgeline has a part of an ellipse and a straight line. It is assumed that the coordinates of a separation point of an ellipse portion from a straight line portion are (x0, y0). The straight line is a tangent to the ellipse at the separation point. It is assumed that a1 is an area from a tip end of the drill to x0, a2 is an area from x0 to the origin of the ellipse, and a3 is a negative area, along the x-axis. The ridgeline of the cutting edge is formed straight along the tangent in the area a1, and is formed along the ellipse in the area a2. A margin is formed in the area a3 continuously from a relief face of the cutting edge.

Owner:SUBARU CORP

Cutting method with auxiliary laser heating for metal strip

ActiveCN102837124AImprove cut qualityShear Yield Strength ControlLaser beam welding apparatusShearing machine accessoriesMetal stripsVolumetric Mass Density

The invention relates to a cutting method with auxiliary laser heating for a metal strip. Laser is adopted to heat and then cut the metal strip. The cutting method is characterized in that heating temperature Th is equal to xi multiplied by A, then multiplied by F, then multiplied by A<x>s, and then multiplied by U<-1.5>, wherein U is the running speed of the metal strip, and the unit of U is m / min; F is the power of a laser device, and the unit of F is W; AS is the laser spot area, and the unit of AS is mm<2>; the xi is a constant correlated to the density and the specific heat capacity of the metal strip, and is equal to (0.3-0.8)e3; x is a constant correlated to the thickness of the metal strip, and is equal to a value between -0.75 and 0.0; the cutting temperature T is equal to Th minus delta T; and the delta T in the formula is the temperature drop of the metal strip. The cutting method has the advantages that the cutting method is high in heating efficiency, and is adapted to high-speed cutting, particularly high-speed cutting of an ultrathin strip with a high-quality requirement.

Owner:BAOSHAN IRON & STEEL CO LTD

Drill and drilling method for workpiece

ActiveUS9180531B2Improve wear resistanceImprove accuracyWood turning toolsTransportation and packagingMaximum diameterEngineering

Owner:SUBARU CORP

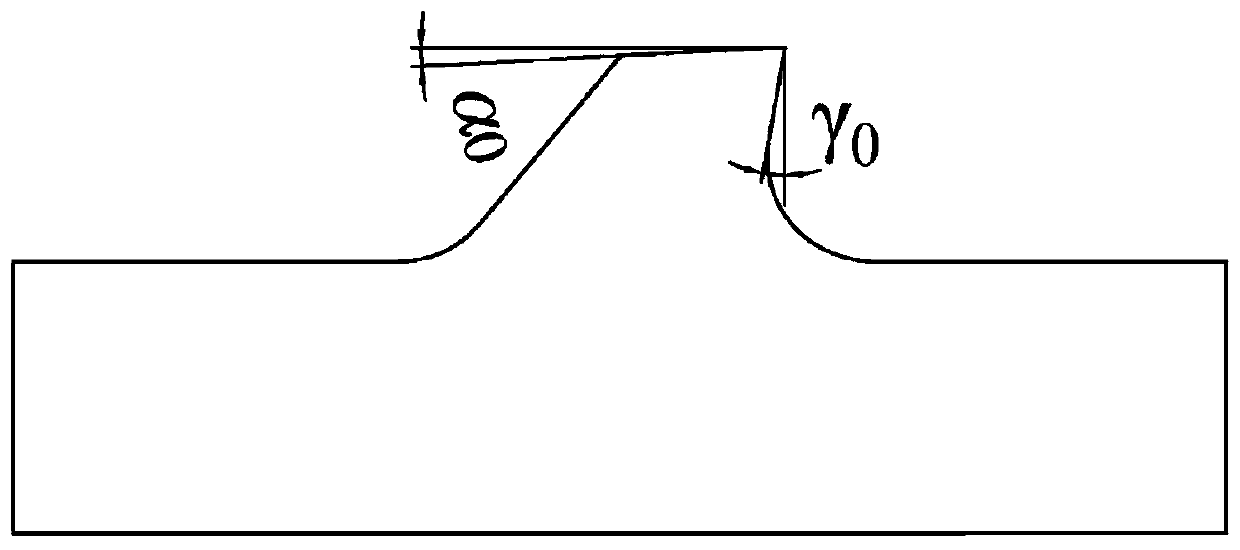

Cutting insert and cutting tool

ActiveUS20190061024A1Small cutting loadNarrow widthTransportation and packagingMilling cuttersEngineeringMechanical engineering

The present invention provides a cutting insert in which suitable honing is formed on a cutting edge. The cutting insert is provided with: two end surfaces opposing each other; a peripheral side surface extending between the two end surfaces; and a cutting edge formed on an intersecting ridge between at least one of the two end surfaces and the peripheral side surface. The cutting edge at least includes a major cutting edge and an inner cutting edge. Honing is provided on the major cutting edge and the inner cutting edge. A width of second honing of the inner cutting edge is narrower than a width of first honing of the major cutting edge, as viewed from a side of the end surfaces.

Owner:TUNGALOY CORP

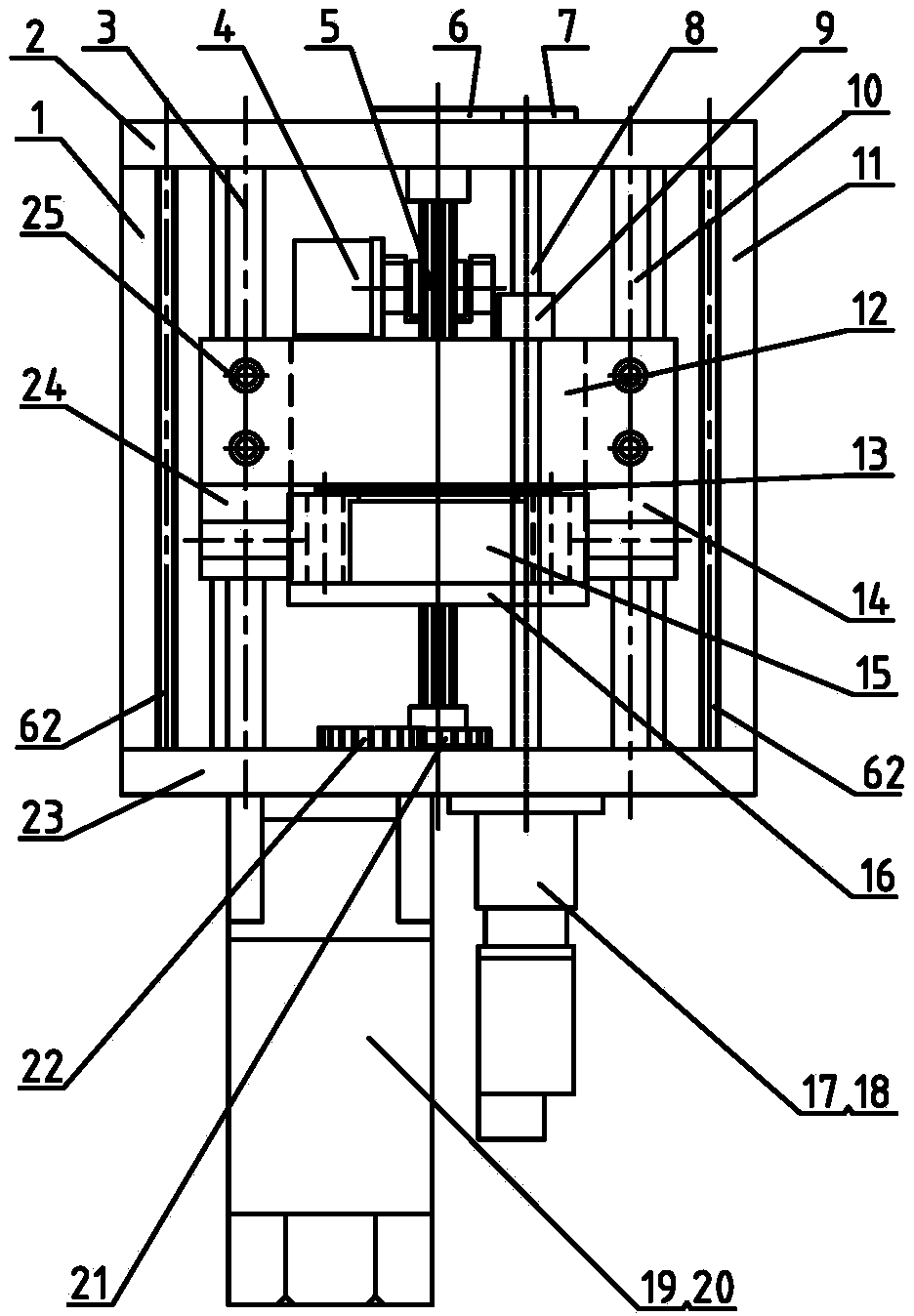

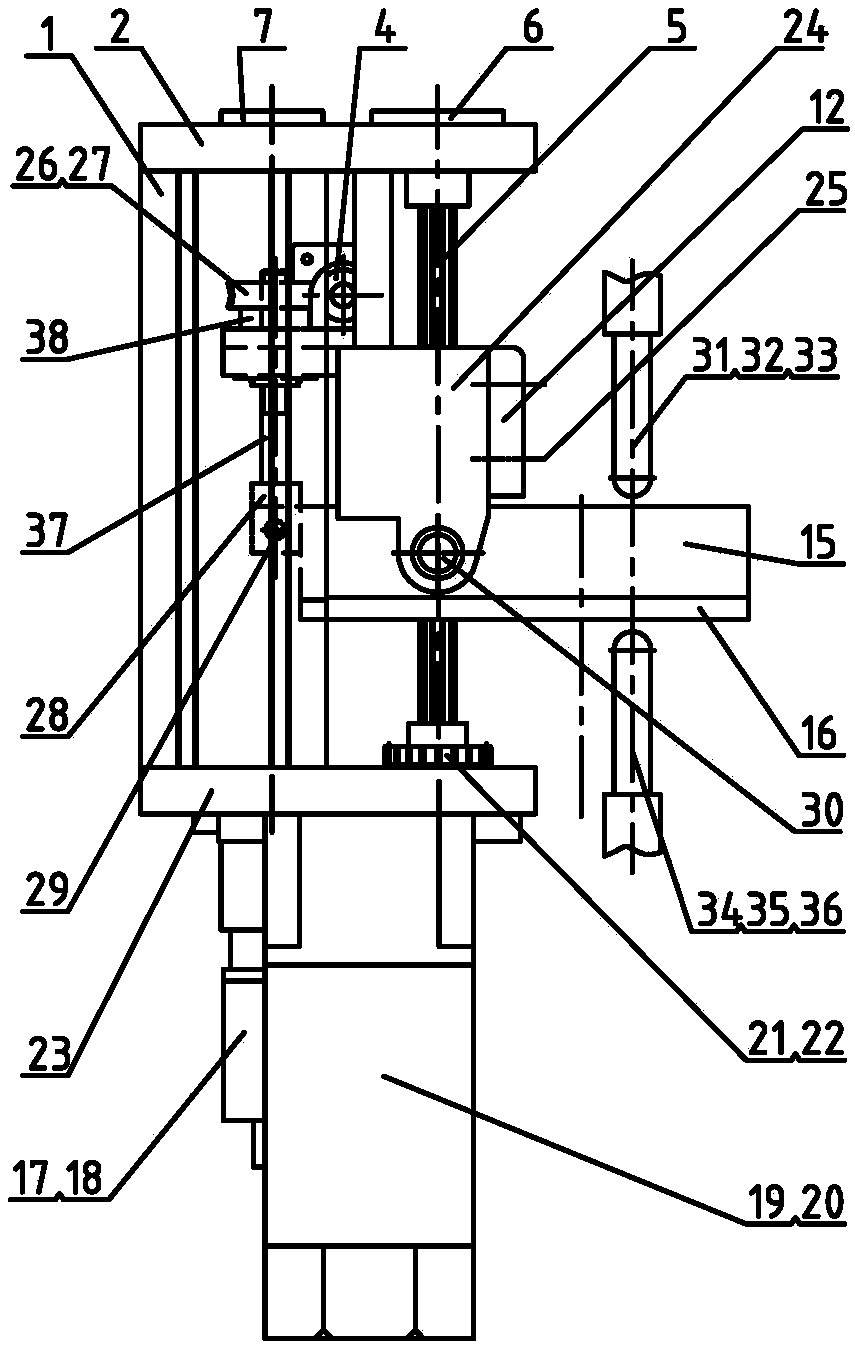

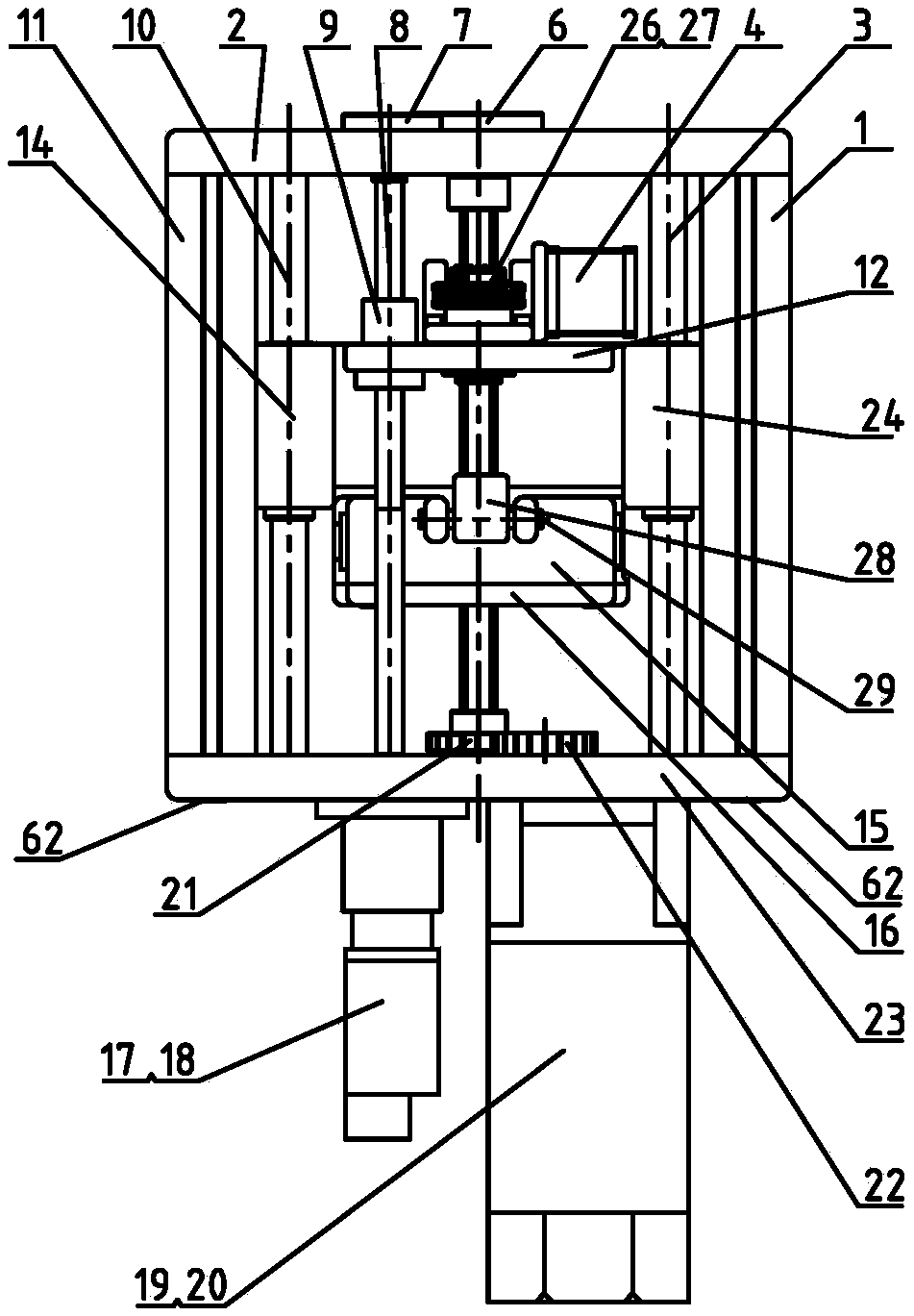

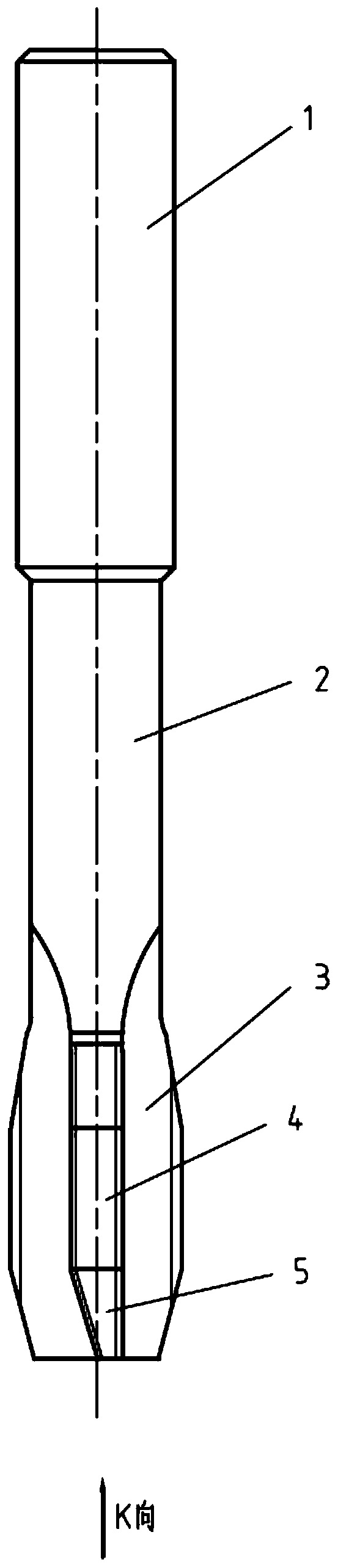

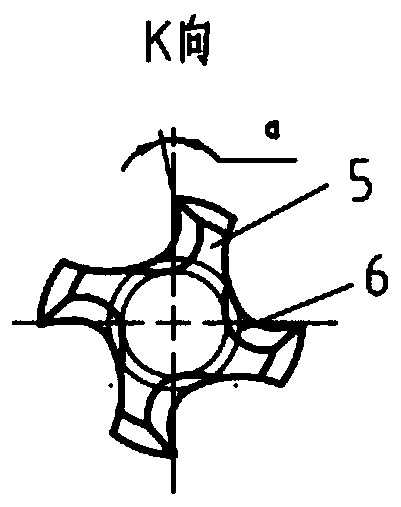

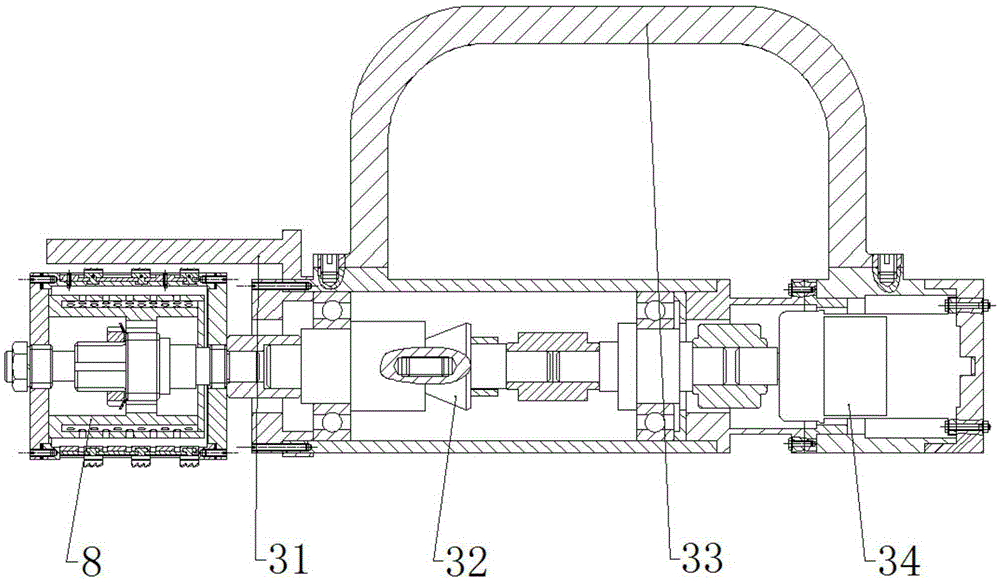

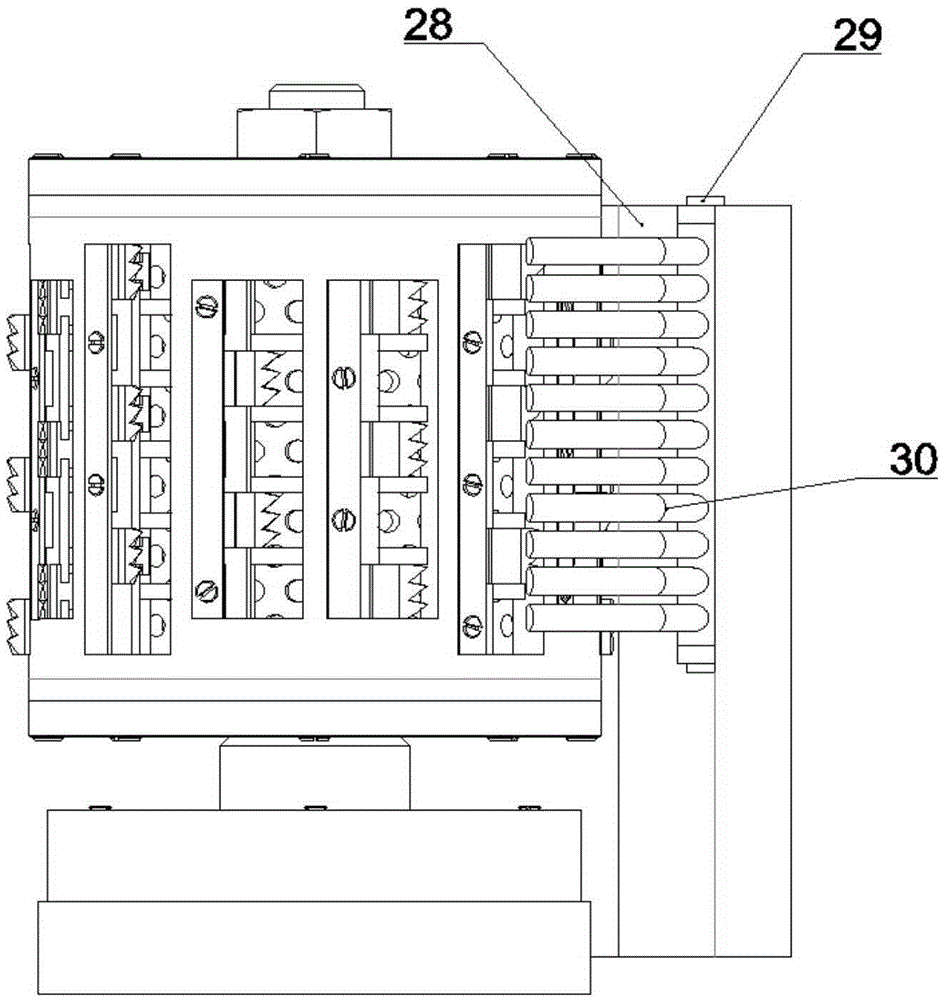

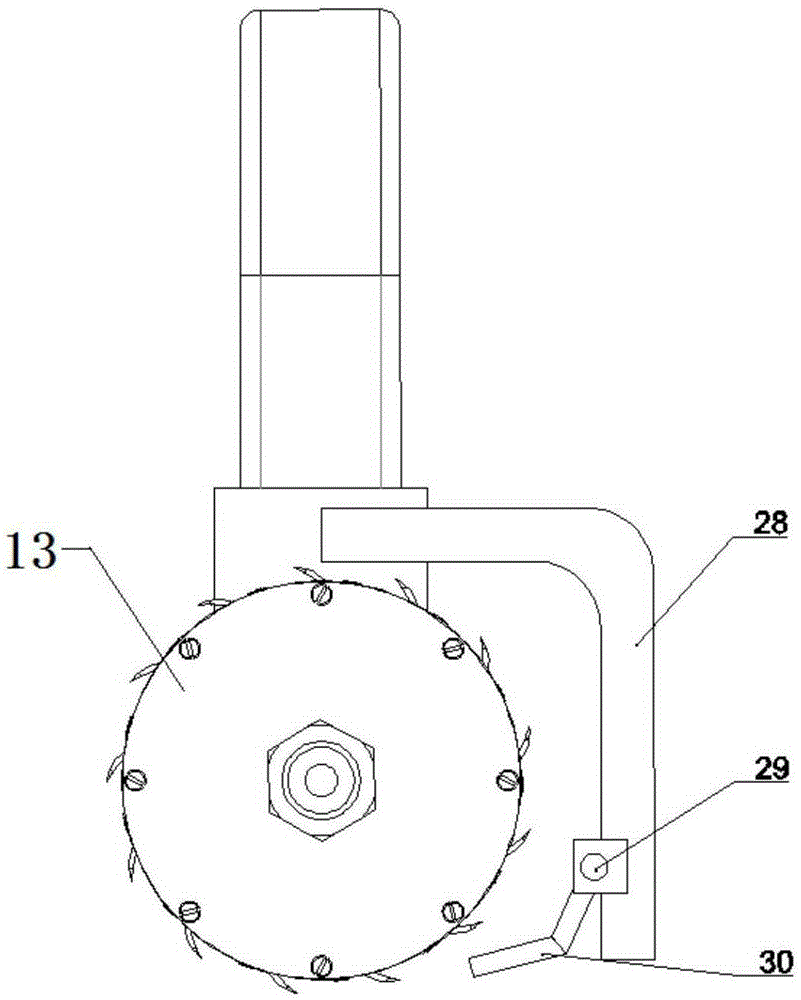

Single working end swing type automatic electrode grinder for resistance spot welding

ActiveCN108161202AEliminate helix angleImprove solder joint qualityWork clamping meansMilling cuttersElectrical resistance and conductanceGear wheel

The invention discloses a single working end swing type automatic electrode grinder for resistance spot welding. The automatic electrode grinder comprises a bracket and a working end frame arranged onthe bracket; the working end frame is internally provided with a working end and a grinding angle compensation system, and the outer side of the working end frame is provided with an electrode positioning mechanism used for electrode grinding; a working end frame floating mechanism is arranged between the bracket and the working end frame; a power input gear, a spline gear, a spline shaft, a ballcage, a gear shaft and a tool rest gear composed of a tool rest and a combined cutting tool are driven by an AC motor in sequence during grinding and cutting; during the cutting displacement of the cutting tool in the grinding process, a screw ball nut, a connecting plate, a support base and the working end are driven by the servo motor in sequence; and the grinding angle compensation system comprises a stepping motor, a worm gear, a bolt tie rod, a connecting block, a hinge pin and so forth. The automatic electrode grinder disclosed by the invention has the abilities of positioning and micro-grinding for the electrode surface, gradually increasing compensation of grinding angles and accurate positioning of electrode grinding positions.

Owner:天津市昊源吉高机械零部件股份有限公司 +1

Distal end screw tap and application thereof

ActiveCN110202221AIncreased torsional strengthExtended service lifeThread cutting toolsThread cutting machinesNeck partsEngineering

The invention discloses a distal end screw tap. The distal end screw tap comprises a handle part, a neck part and a work part. A core part, a calibration part, a cutting part and a chip containing groove are machined on the work part. The cutting part is located at the most front end of the work part, and threads are machined on the calibration part and the cutting part. The number of grooves is increased for the screw tap with the specification of M8-M14, and the diameter of the core part is increased; and the point of view that the cutting thickness is accurately controlled within 0.05 mm to0.06 mm and the point of view of reducing the length of the calibration part so as to reduce cutting resistance are put forwards. By means of the distal end screw tap, the design concept that the neck part, the handle part and the chip containing groove of the screw tap are long is put forwards, the twisting off resisting capability of the screw tap is improved, clamping force is improved, and the risk that tapping is not synchronous is effectively lowered. By means of the distal end screw tap, the strength of the distal end screw tap is high, and the distal end screw tap can be used for machining quenched and tempered steel parts with the HRC being 32 or higher.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

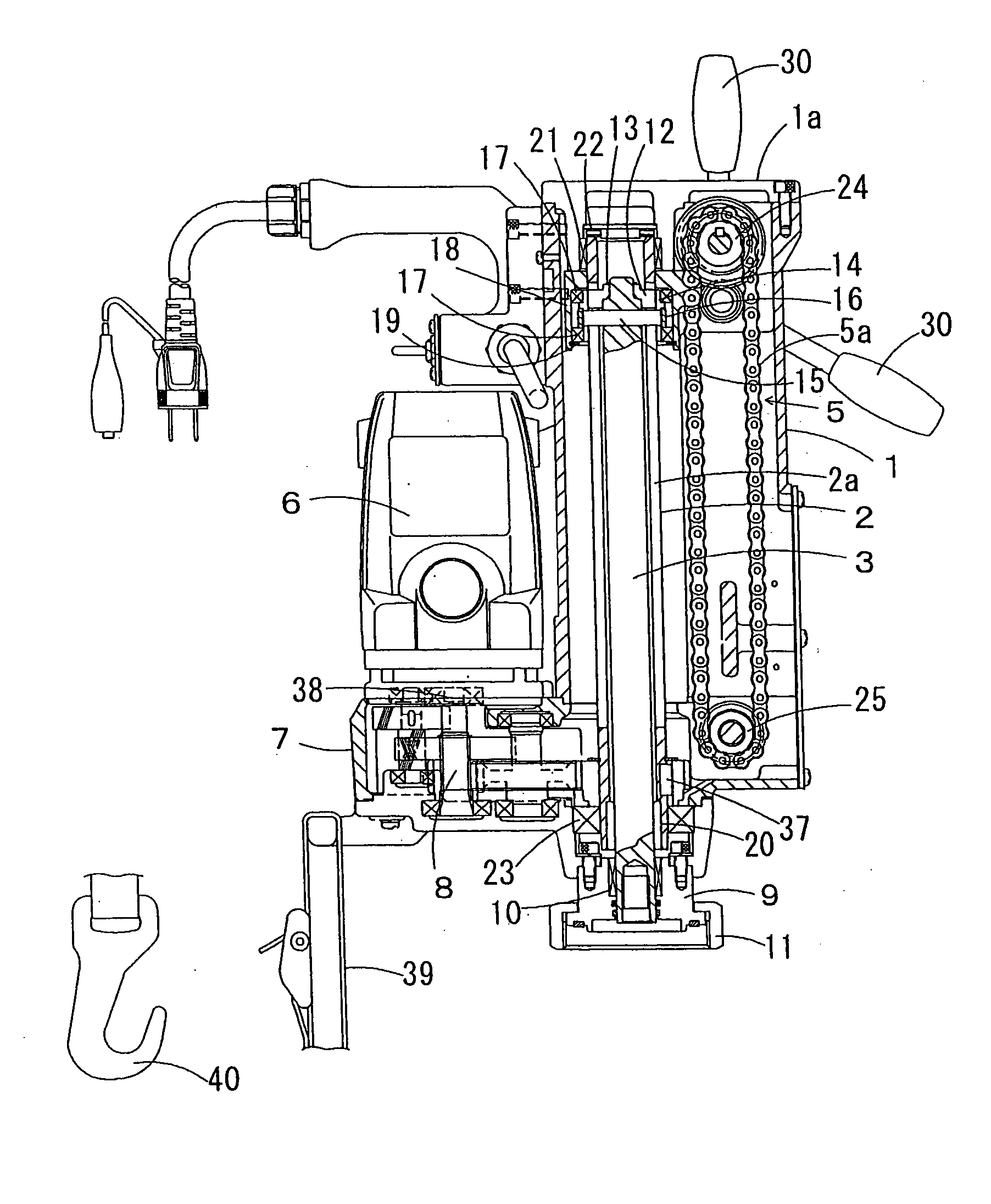

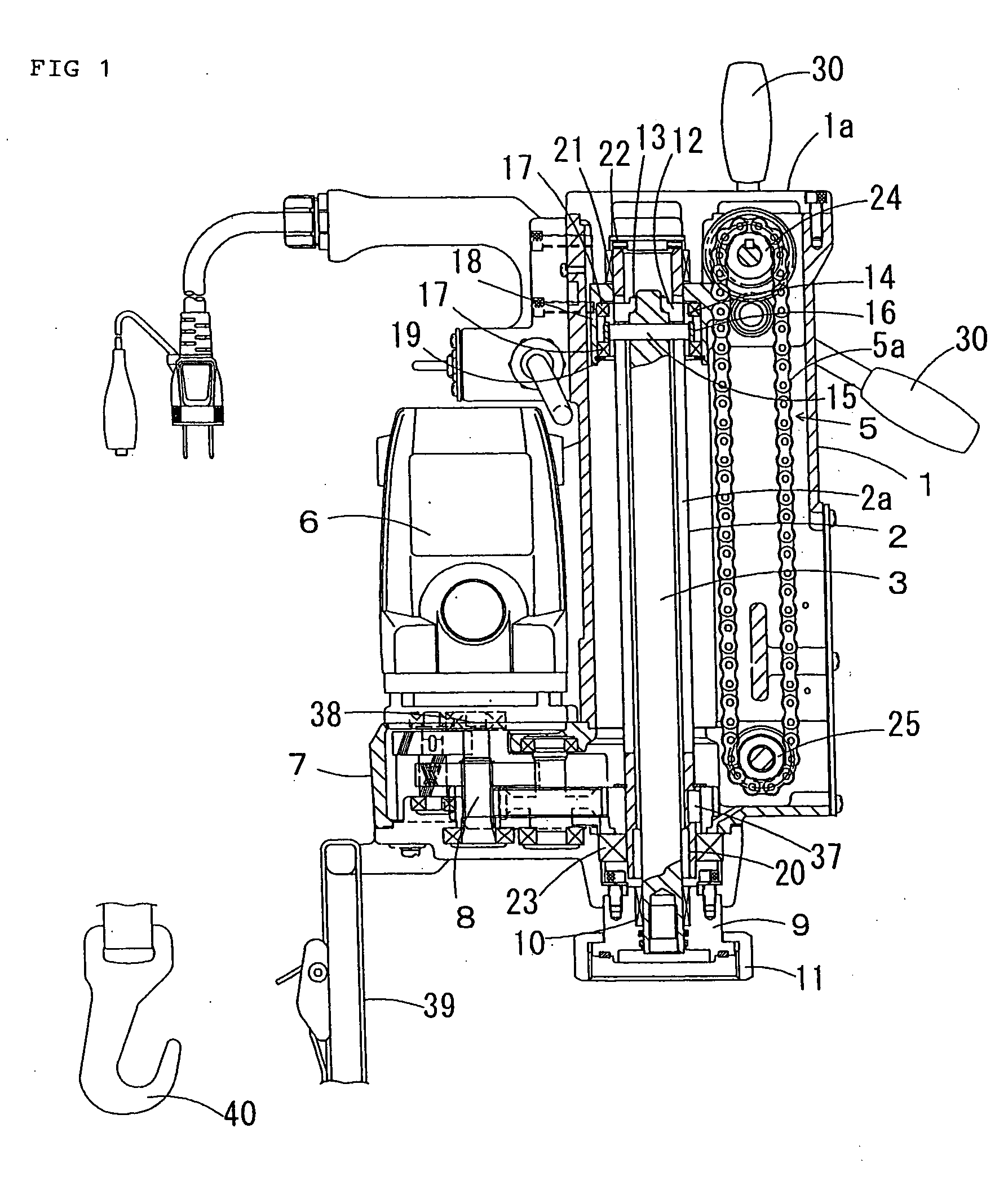

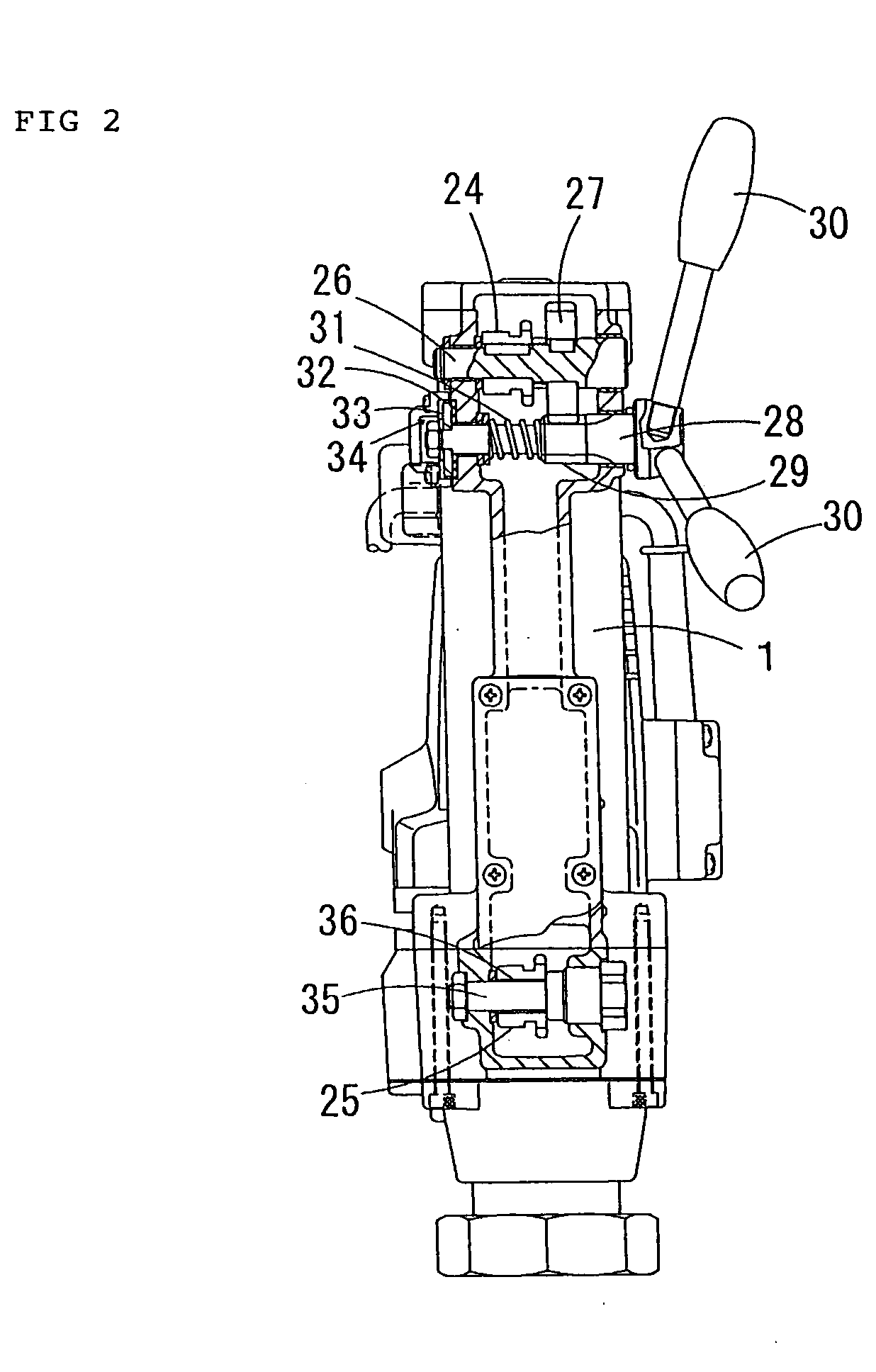

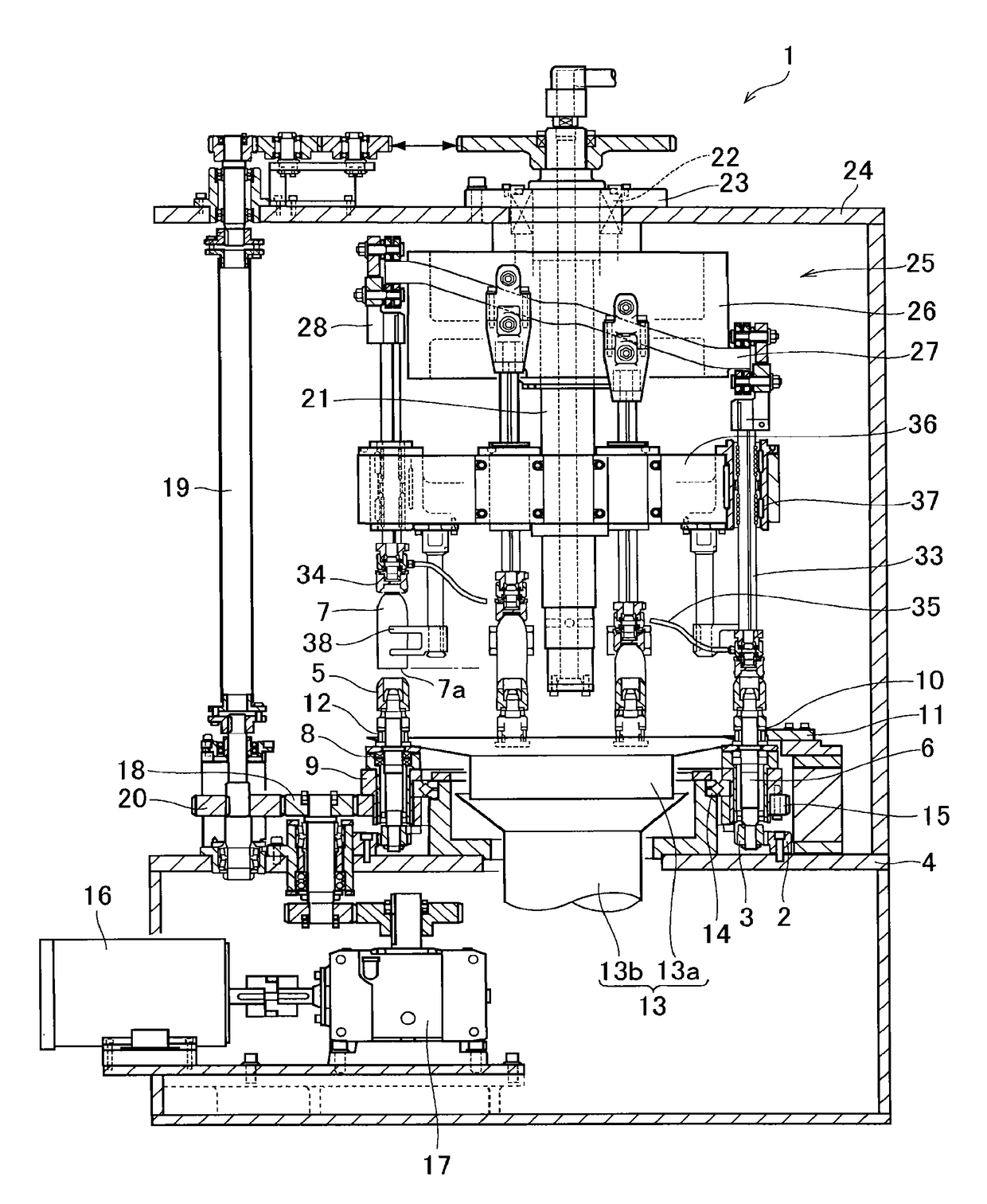

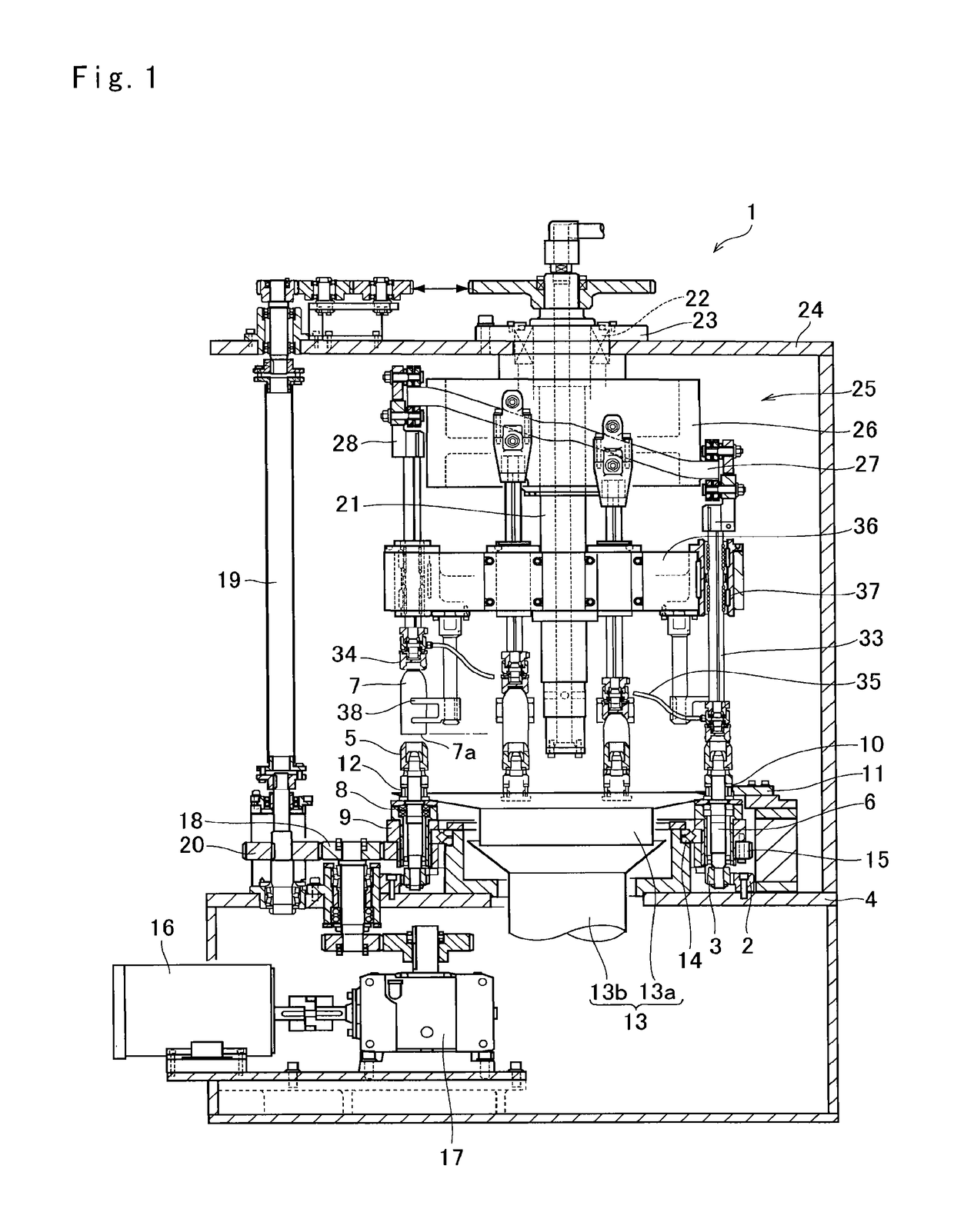

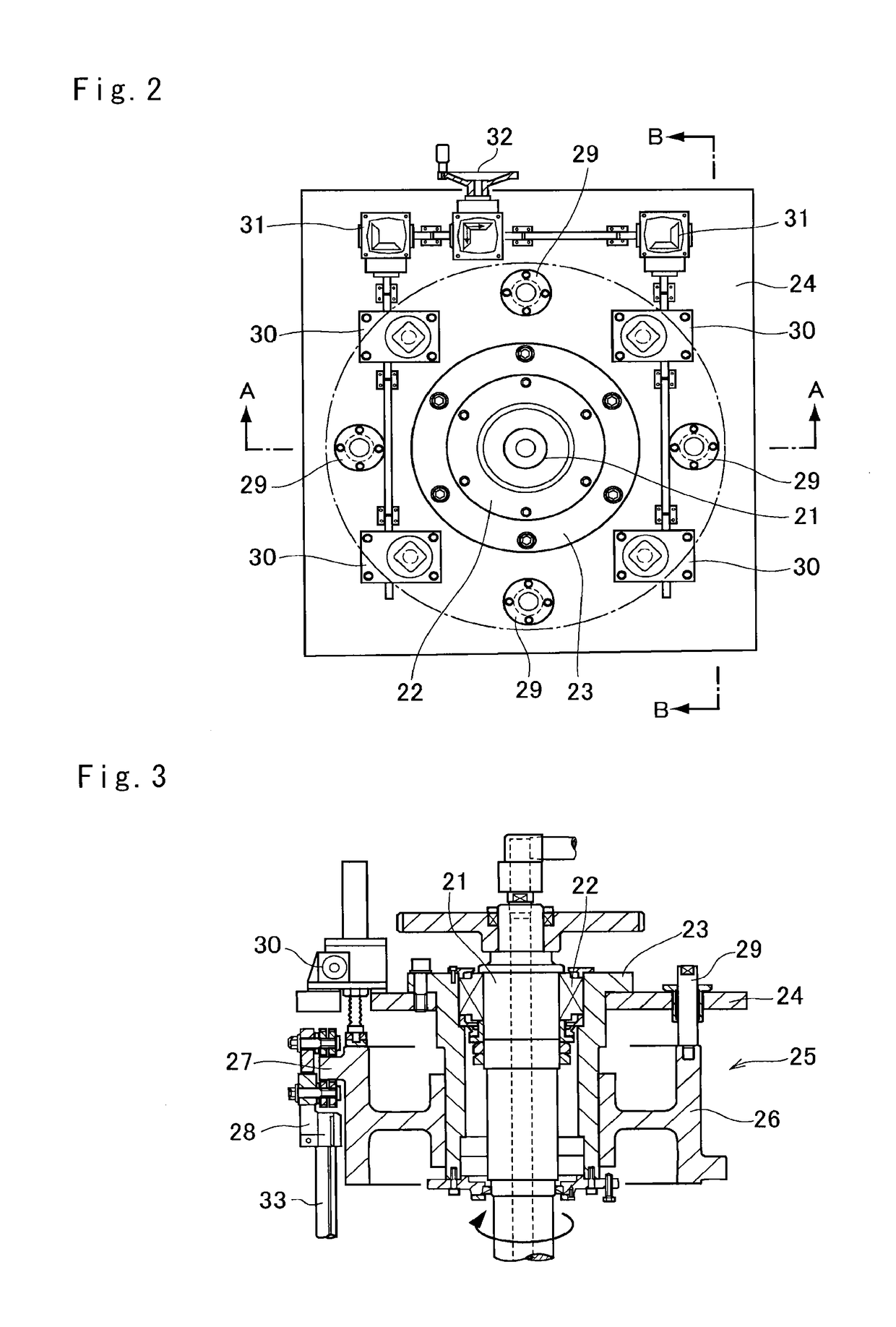

Boring machine

InactiveUS20060175095A1Reducing rotation radiusHigh torqueEarth drilling toolsBorehole drivesMaximum torqueEngineering

In a boring machine, rotation of a motor is transferred to a pipe spindle and a shaft, a cutting edge feeding mechanism arranged side by side with the pipe spindle moves the shaft toward a workpiece and a cutting edge attached to an end of the shaft drills a hole in the workpiece. The cutting edge feeding mechanism slidably but non-rotatably supports a chain holder around an outer circumference of the pipe spindle. A sprocket wrapped around by a chain is rotated by a handle to move the shaft. The radius of rotation of the handle is reduced to slowly move the shaft. The maximum torque of the motor rotating the shaft is controlled. The number of cutting edges falls within a range from six to eight.

Owner:TABUCHI

Program writing method of numerical controller, numerical controller and cutting machine controlled thereby

ActiveUS7818080B2Improve accuracyReduce cutting loadProgramme controlGrinding feed controlMachine controlVirtual control

Owner:JTEKT CORP

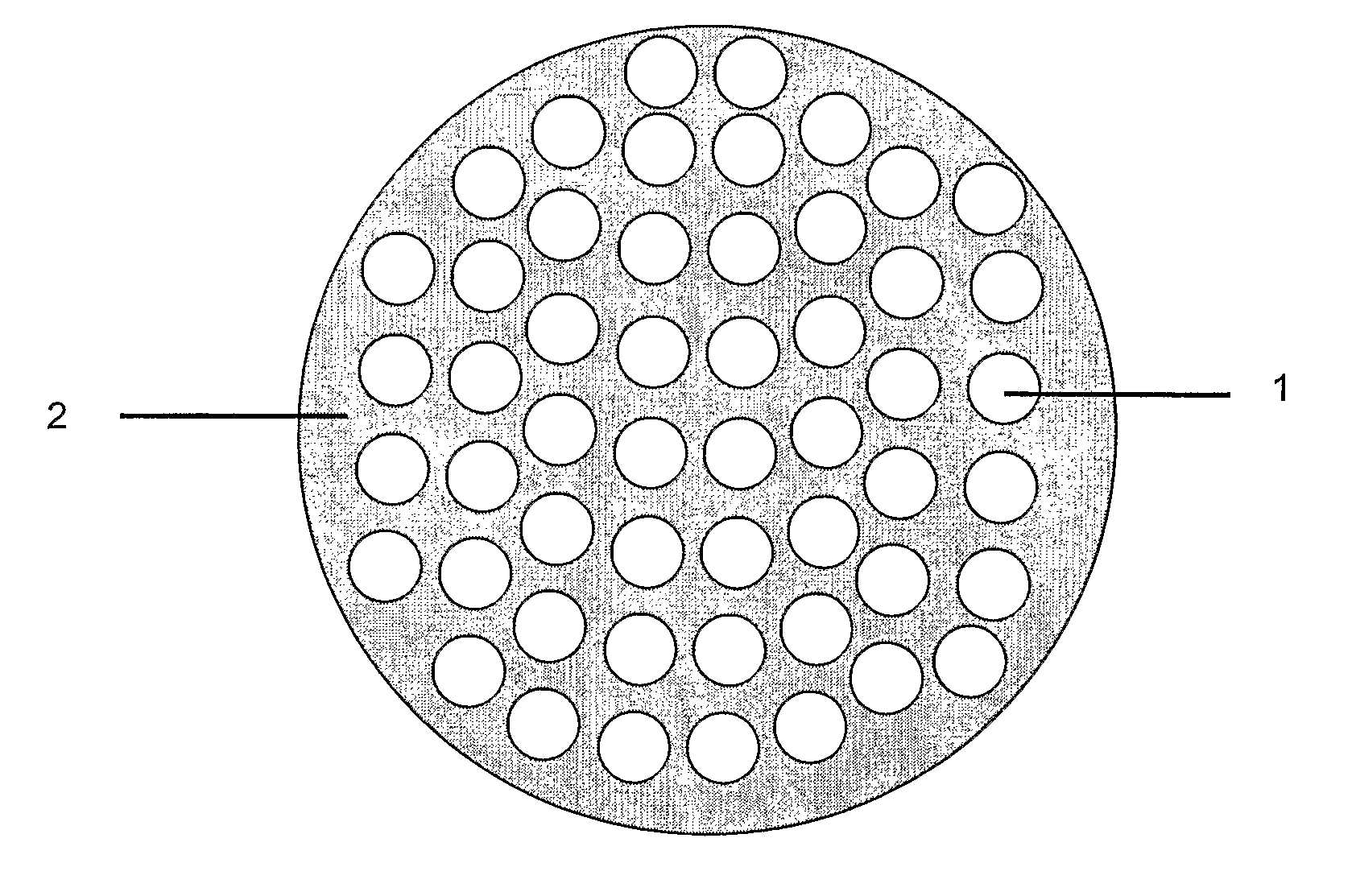

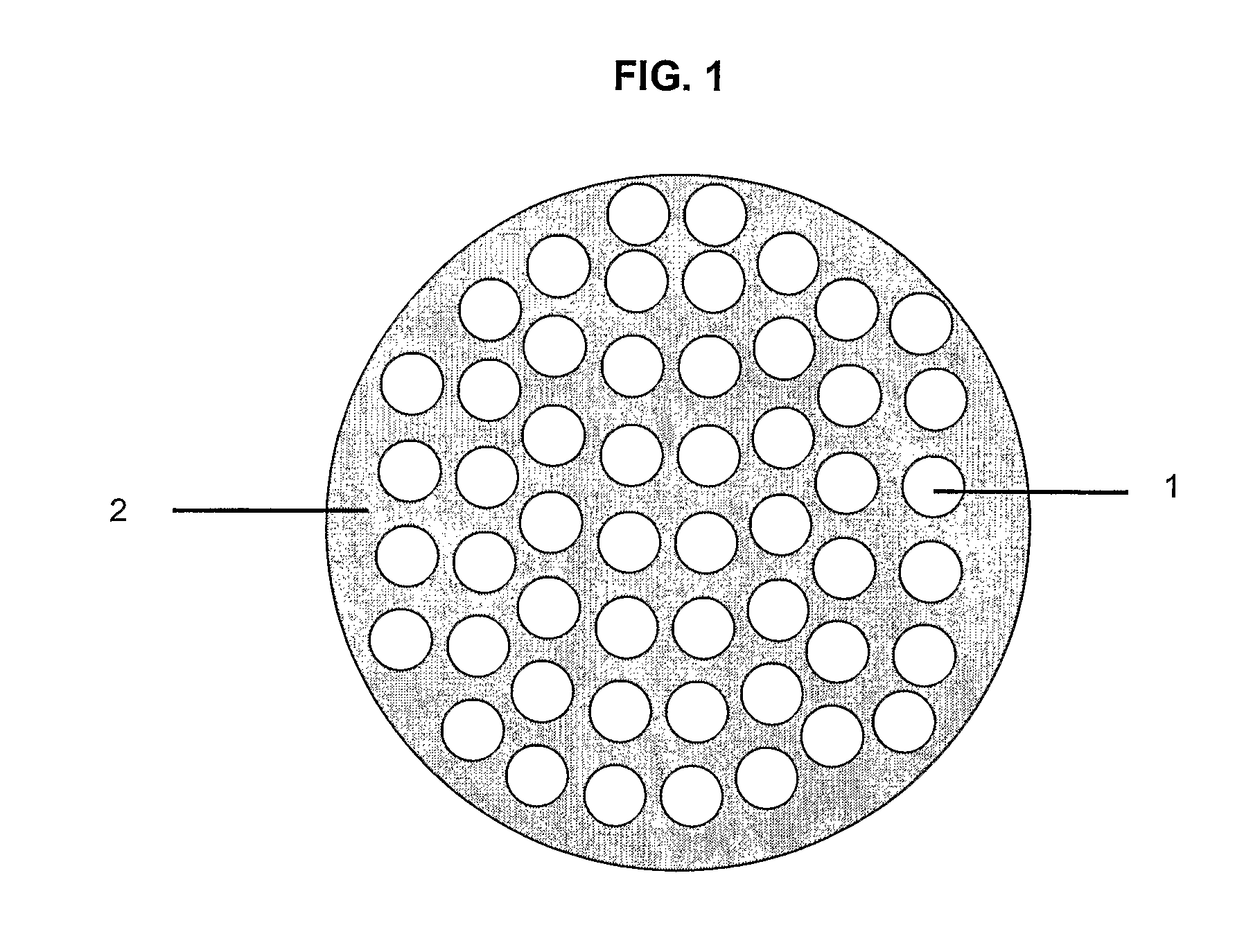

Method and device for multi-line silicon chip cutting with free-solidified compound abrasives

InactiveCN110497546AIncrease contact areaImprove cutting performanceWorking accessoriesGrinding machinesDiamond grindingSilicon chip

A method and device for multi-line silicon chip cutting with free-solidified compound abrasives belong to the technical field of processing of semiconductor materials and solve problems in silicon crystal slicing. The method for multi-line silicon chip cutting with the free-solidified compound abrasives comprises the steps that a silicon crystal ingot is cut through multi-line cutting with solidified abrasives, and a grinding solution containing suspended diamond abrasive granules is sprinkled to a cut area; and a metal wire with the diamond abrasive particles solidified on the surface bringsthe grinding solution containing the suspended diamond grinding particles into a cutting seam of the silicon crystal ingot during wire walking, so joint effects of free abrasives and the solidified abrasives are formed to jointly cut the silicon crystal ingot, and the silicon crystal ingot is cut into multiple slices during one time of processing. The device for multi-line silicon chip cutting with the free-solidified compound abrasives comprises a free abrasive multi-line cutting device, wherein the diamond abrasive particles are solidified on surfaces of all the metal wires of the free abrasive multi-line cutting device. The method and device provided by the invention are applied to cutting of silicon chips.

Owner:HARBIN UNIV OF COMMERCE

Roughing and finishing integrated hard alloy dry-cutting hob

InactiveCN111922448AImprove machining accuracyShort processGear teeth manufacturing toolsGear teethGear wheelAlloy

The invention discloses a roughing and finishing integrated hard alloy dry-cutting hob and belongs to the technical field of gear machining tools. The roughing and finishing integrated hard alloy dry-cutting hob comprises a hob body, a roughing hob set and a finishing hob set, wherein the center of the hob body is provided with a hob locating hole in the axial direction; the hob body, the roughinghob set and the finishing hob set are all made of hard alloy, the inner wall of the hob locating hole is provided with a key groove in key connection with a hobbing machine tool spindle, the roughinghob set and the finishing hob set are detachably and fixedly connected to the hob body respectively, multiple V-shaped roughing hob chip containing grooves are uniformly distributed in the outer circle surface of the roughing hob set, multiple V-shaped finishing hob chip containing grooves are uniformly distributed in the outer circle surface of the finishing hob set, a roughing front cutting edge and a roughing side cutting edge are arranged on the front surface of each roughing hob blade in the roughing hob set, and a finishing front cutting edge and a finishing side cutting edge are arranged on the front surface of each finishing hob blade in the finishing hob set. The hob is used for roughing and finishing of a gear.

Owner:HARBIN UNIV OF SCI & TECH

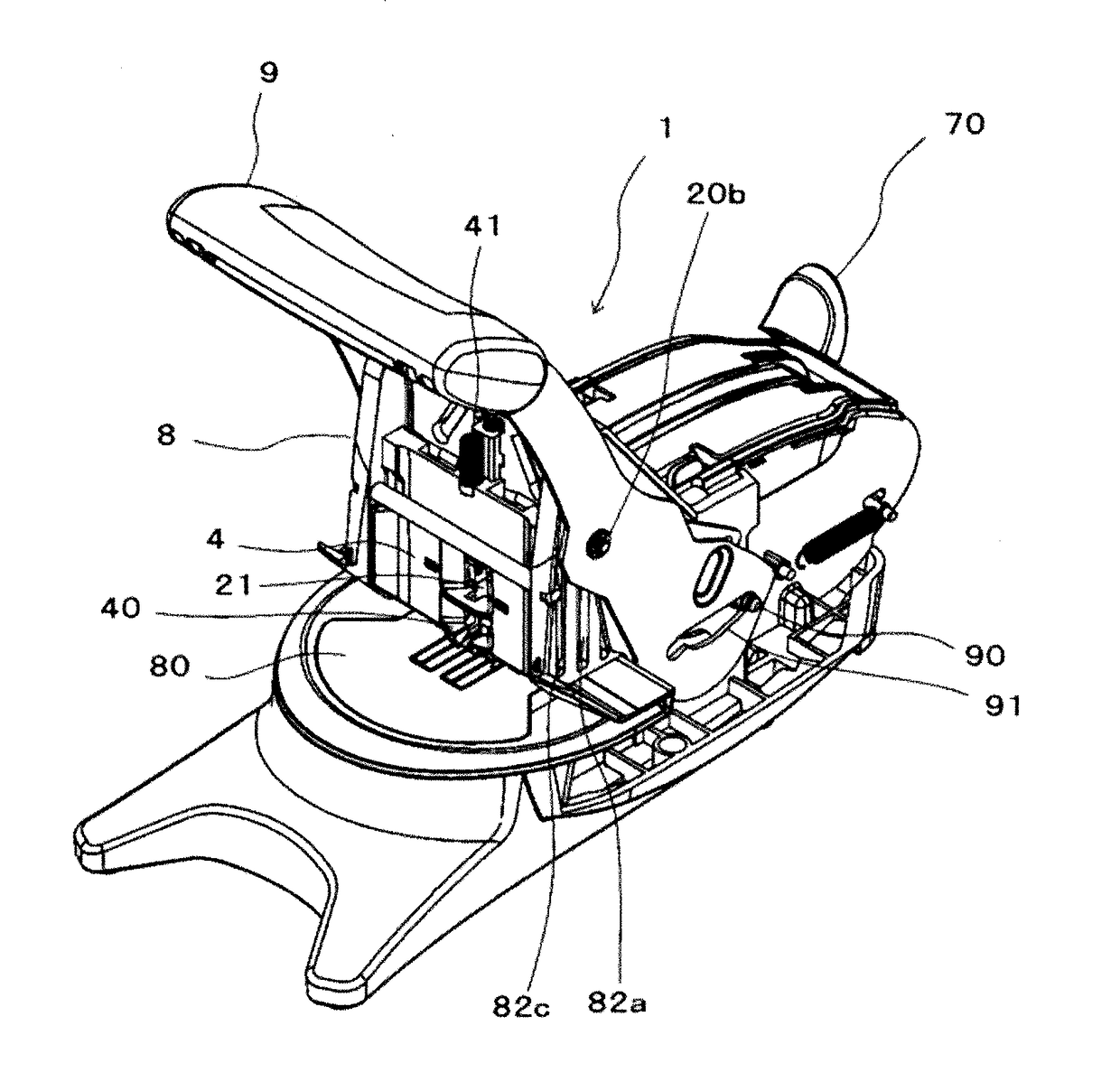

Stapler

ActiveUS20170087700A1Reduce contact lengthEasy loadingStapling toolsStaplesEngineeringSoft materials

A stapler is configured to bind a workpiece using a staple made of a non-metal soft material. The staple has a crown portion and a pair of leg portions formed by bending both longitudinal ends of the crown portion toward one direction. The stapler includes a placing base, a penetrating part, an opening, and a pressing portion. The opening is provided on the placing base so that the one pair of cutting blades and the one pair of leg portions of the staple inserted into the workpiece pass through the opening. The pressing portion that is provided in the opening of the placing base and suppresses deformation of the workpiece caused by a force applied to the workpiece from the cutting blades when the cutting blades penetrate the workpiece.

Owner:MAX CO LTD

Deep-second-degree burn wound high-speed rotating eschar excision device

ActiveCN105286949AFlexibleReduce cutting loadIncision instrumentsExcision instrumentsSecond-Degree BurnStress conditions

The invention discloses a deep-second-degree burn wound high-speed rotating eschar excision device, which comprises a cutter head, wherein the cutter head is connected with a rotating power source through a transmission mechanism; a vibration mechanism is arranged in the middle of the transmission mechanism; the cutter head comprises a cutter frame; and a plurality of cutters used for eschar excision are arranged on the cutter frame. The deep-second-degree burn wound high-speed rotating eschar excision device has the beneficial effects that a cutter adopts a bent wedge-shaped structure and is provided with an elastic element, so that the telescopic flexibility of the cutting is realized; the change of an eschar excision load in a certain range can be borne; the stress condition is improved; when the preset load upper limit is exceeded, the automatic retraction is realized; the occurrence of medical accidents due to excessive excision on the burn wound part is avoided; by arranging a negative pressure adsorption tube, the collection of cut eschar fragments is realized; cut eschar fragments are prevented from falling into the device or other space positions; and the use neatness of the device is ensured. The whole device has the advantages that the structure is compact; the medical effect is good; the anti-contamination capability is high; and the portability is realized.

Owner:SHANDONG UNIV

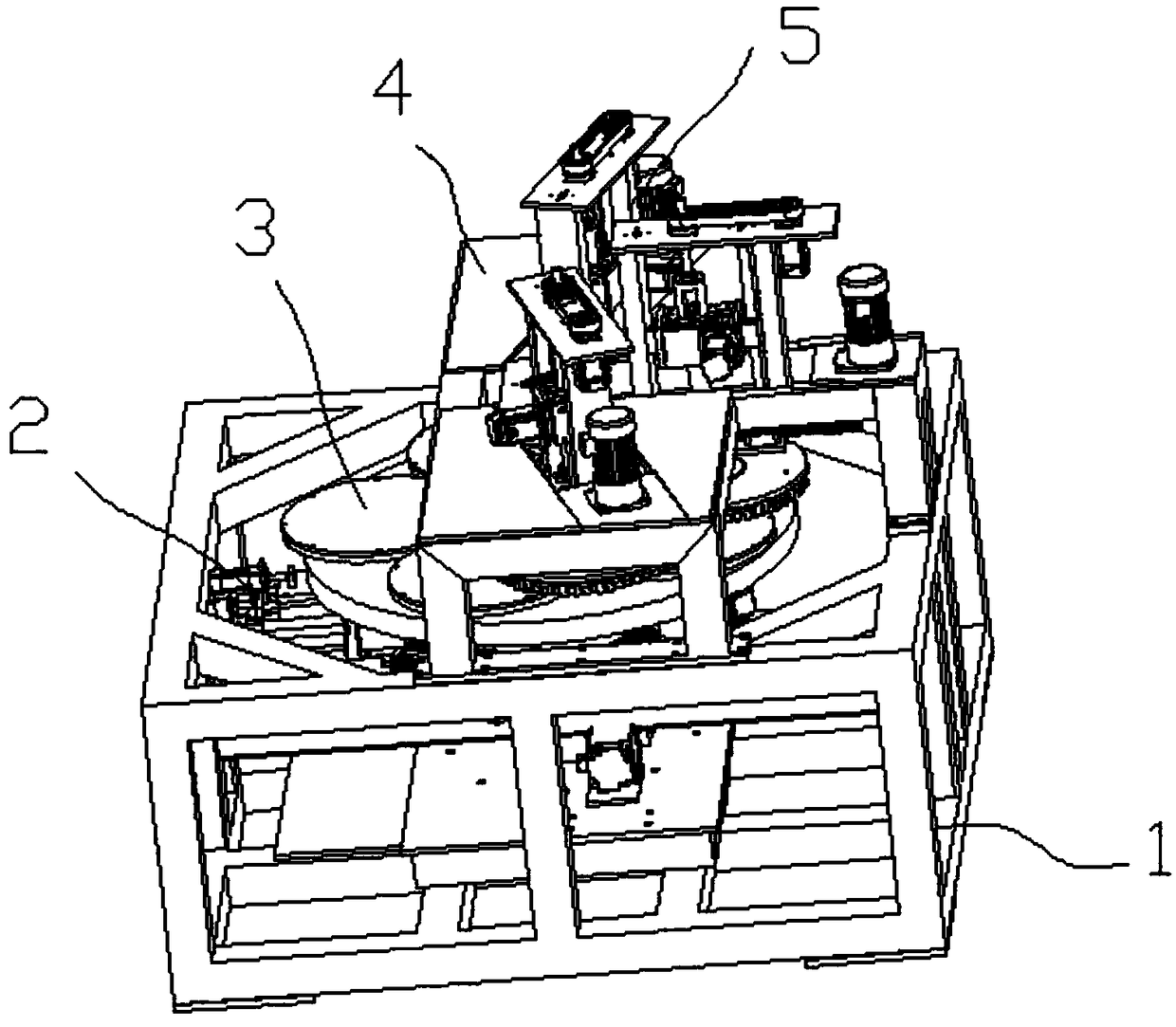

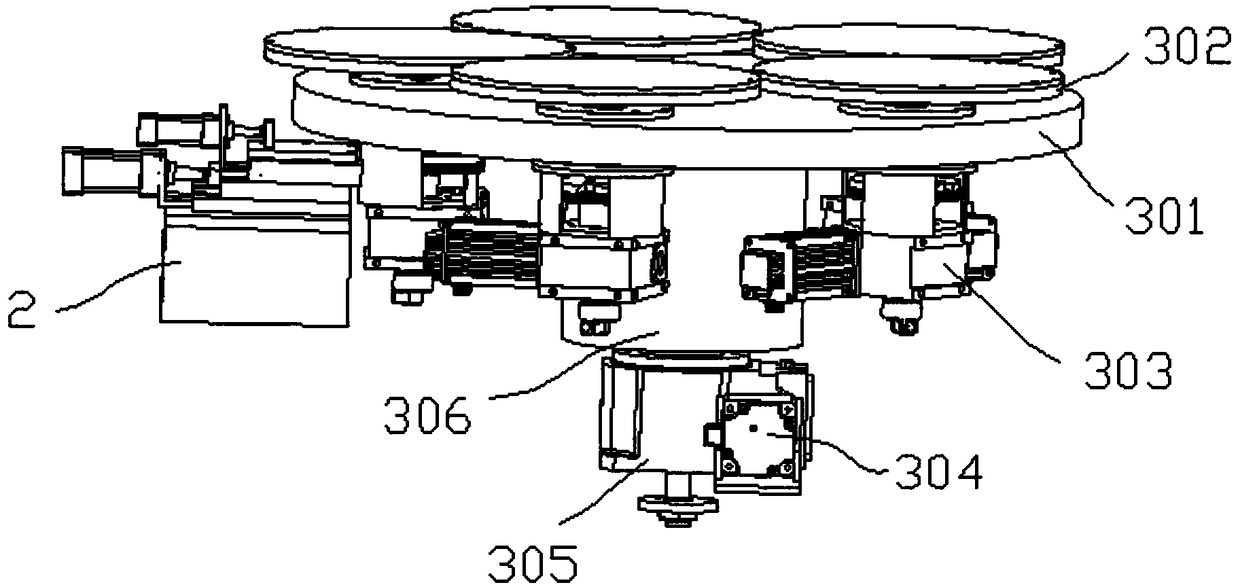

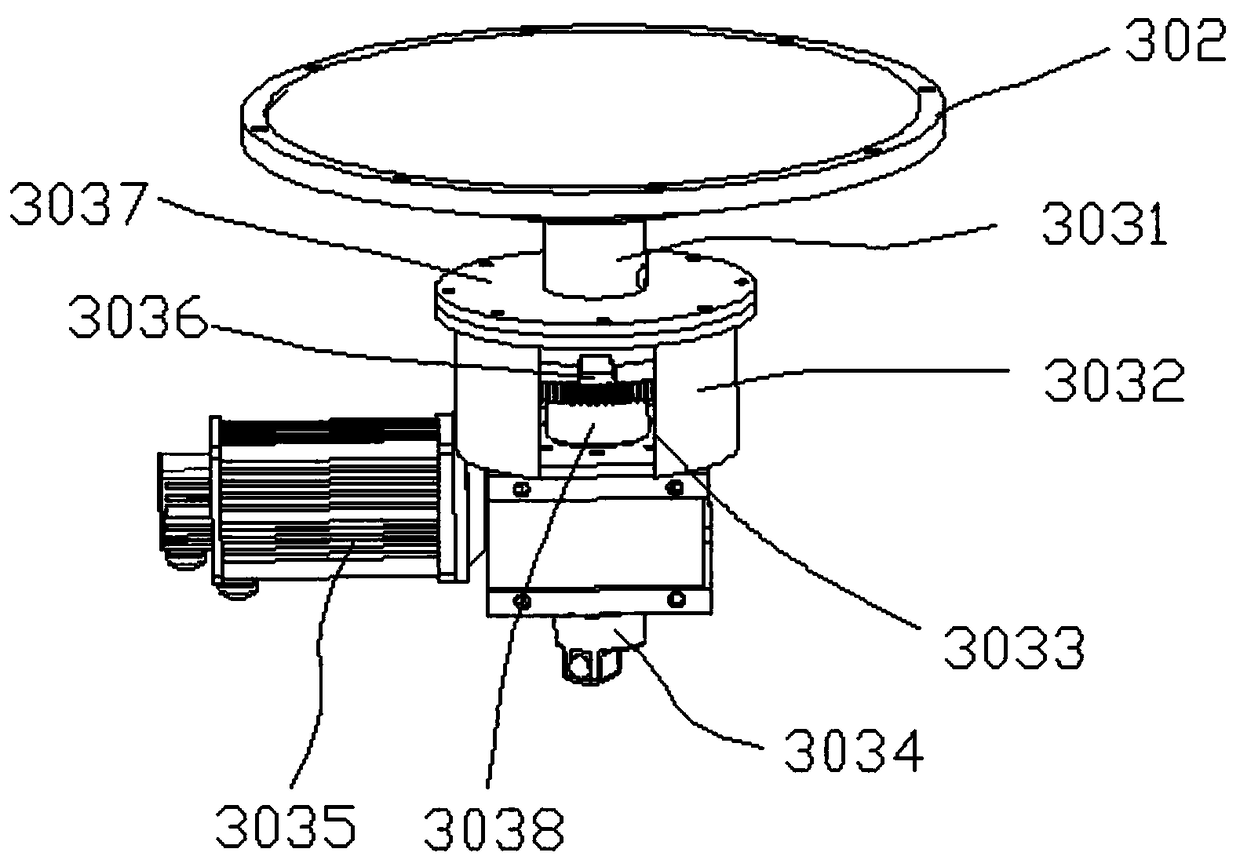

Intelligent positioning plane refine grinding machine

InactiveCN109202656APrecise positioningAutomatically adjust cutting forceGrinding machinesAutomatic grinding controlPulp and paper industryCutting force

The invention discloses an intelligent positioning plane refine grinding machine. The intelligent positioning plane refine grinding machine comprises a bottom frame and a multi-work position rotationplatform; the multi-work position rotation platform is mounted on the bottom frame; the bottom frame is provided with a dovetail positioning mechanism for precisely positioning the multi-work positionrotation platform; the upper end of the bottom frame is provided with a supporting frame; and a multi-work position grinding cutting mechanism is mounted on the supporting frame. With the intelligentpositioning plane refine grinding machine provided by the invention adopted, the accurate positioning of a workpiece in a pick-and-place process can be realized; a cutting force can be automaticallyadjusted; and the production quality of products is improved through swing polishing.

Owner:湖南晶日智能设备科技有限公司

Cutting insert and cutting tool

ActiveUS10525540B2Reduce cutting loadLess susceptible to edge fractureTransportation and packagingMilling cuttersStructural engineeringKnife blades

The present invention provides a cutting insert in which suitable honing is formed on a cutting edge. The cutting insert is provided with: two end surfaces opposing each other; a peripheral side surface extending between the two end surfaces; and a cutting edge formed on an intersecting ridge between at least one of the two end surfaces and the peripheral side surface. The cutting edge at least includes a major cutting edge and an inner cutting edge. Honing is provided on the major cutting edge and the inner cutting edge. A width of second honing of the inner cutting edge is narrower than a width of first honing of the major cutting edge, as viewed from a side of the end surfaces.

Owner:TUNGALOY CORP

Height adjustment apparatus for a can body

ActiveUS9700948B2Reduce loadReduce cutting loadShearing machinesHollow articlesReciprocating motionOrbit

A height adjustment apparatus that can reduce a load to trim a can body is provided. The height adjustment apparatus 1 is adapted to adjust a height of a can body to a desired height by trimming one of opening ends of the can body. The height adjustment apparatus comprises: mandrels on which the can body is individually mounted and which revolve along a predetermined orbit while rotating; outer blades arranged around the revolution orbit of the mandrels; an inner blade fitted onto each mandrel to trim the opening end of the can body together with the outer blade; and a vertical reciprocator that gradually changes a level of the opening end of the can body with respect to a level at which the outer blade and the inner blade are situated from an upstream side toward a downstream side in a revolution direction of the mandrel.

Owner:DAIWA CAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com