Boring machine

a boring machine and cutting edge technology, applied in earth drilling and mining, earth drilling tools, pipe/joints/fittings, etc., can solve the problems of cutting edge biting or breaking the cutting edge, cutting force, cutting edge crashing into the workpiece, etc., to achieve the effect of reducing the radius of rotation of the handle, and large torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

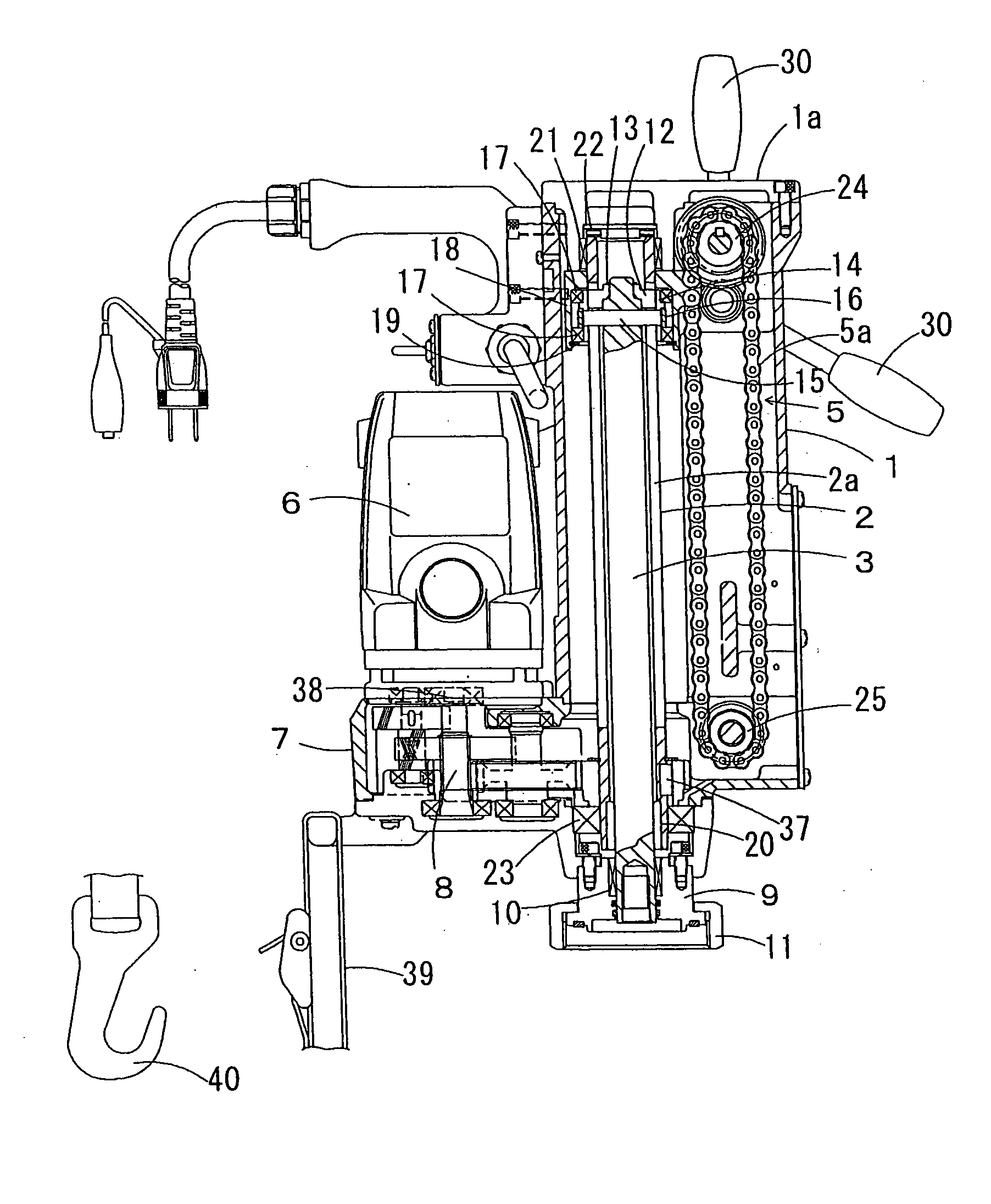

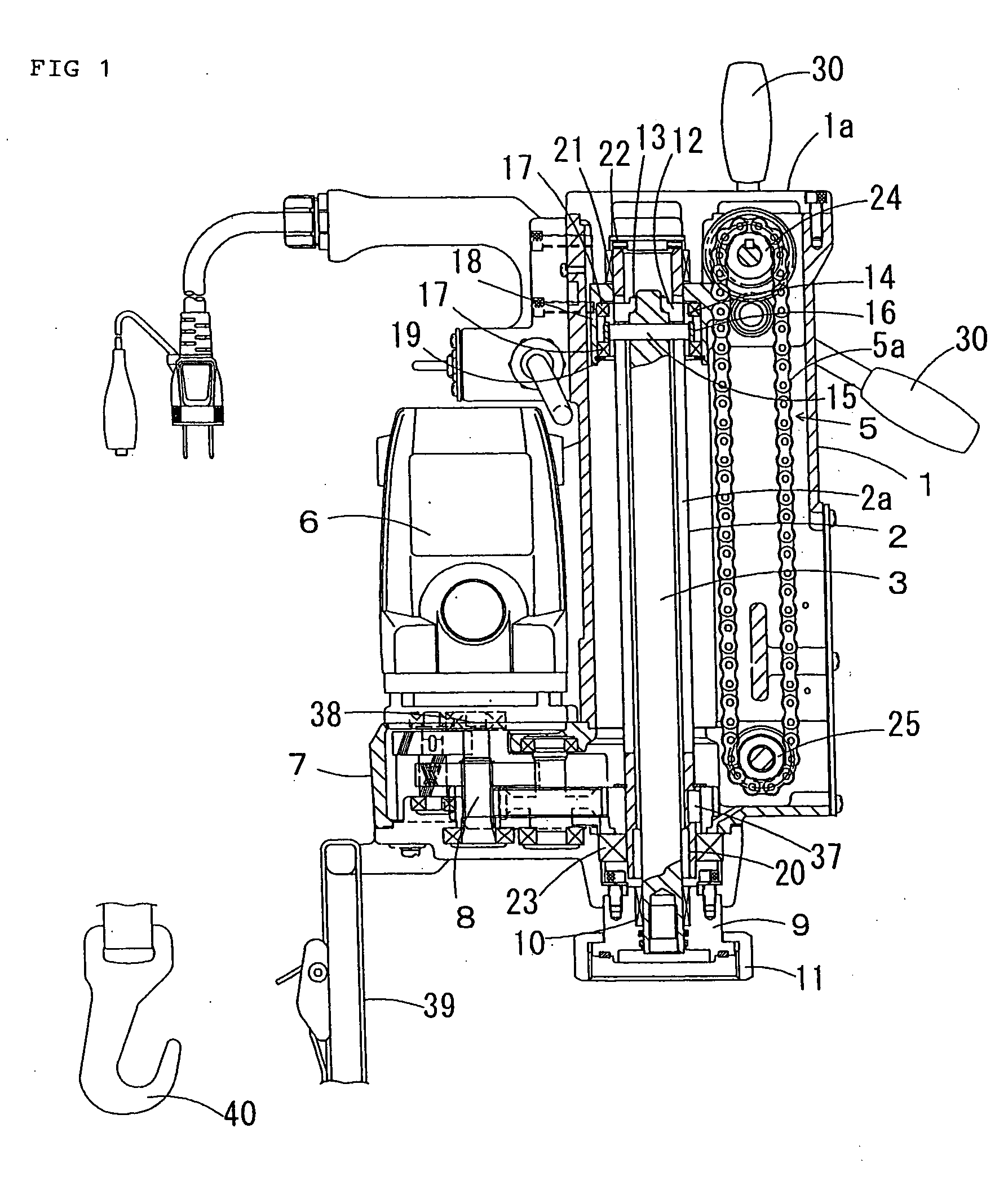

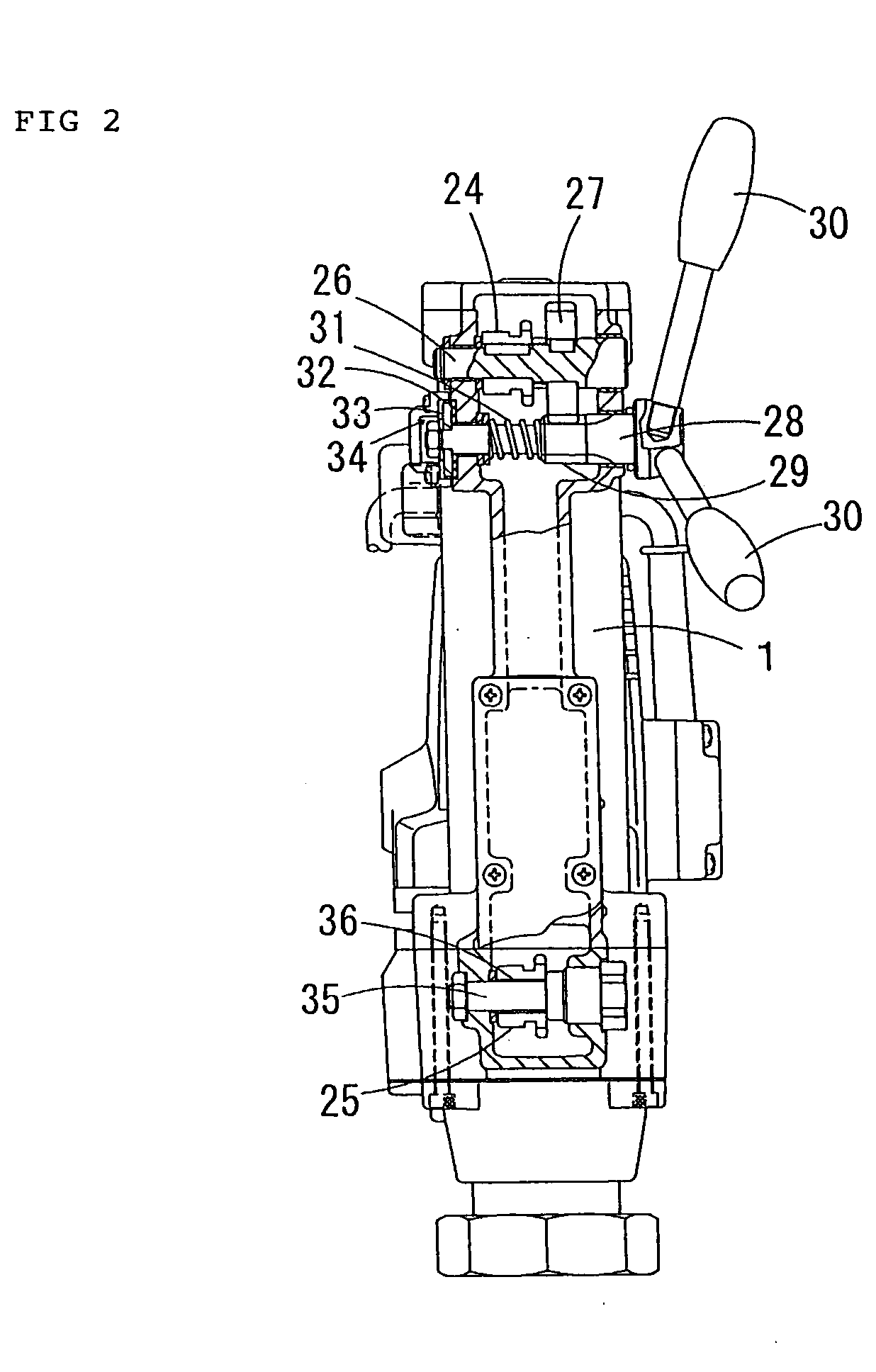

[0019] Boring machines of the preferred embodiments of the present invention are described below with reference to the drawings. FIG. 1 is a side view of the boring machine of one embodiment of the present invention with a portion thereof of broken away, FIG. 2 is a front view of the boring machine with a portion thereof of broken away, and FIG. 3 is a partial side view of the boring machine attached onto a saddle corporation stop.

[0020] Referring to FIGS. 1 through 3, there are shown a boring machine 1, a pipe spindle 2 rotatably supported within the boring machine 1, and a shaft 3 vertically slidably supported within the pipe spindle 2. A cutting edge 4 for cutting a water pipe is mounted to an end of the shaft 3 with a mounting shaft. A cutting edge feeding mechanism 5, employing a chain, vertically moves the shaft 3 through the pipe spindle 2. A motor 6 rotates the pipe spindle 2 and the shaft 3 via a reduction gear train 8 in a gear box 7. A saddle bracket 9 is fixed on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com